Search

Unveiling the Secrets Behind FPC Flexible Circuit Board Pricing: A Comprehensive Analysis of Material and Process Costs

- Apr 24,2025

-

Share

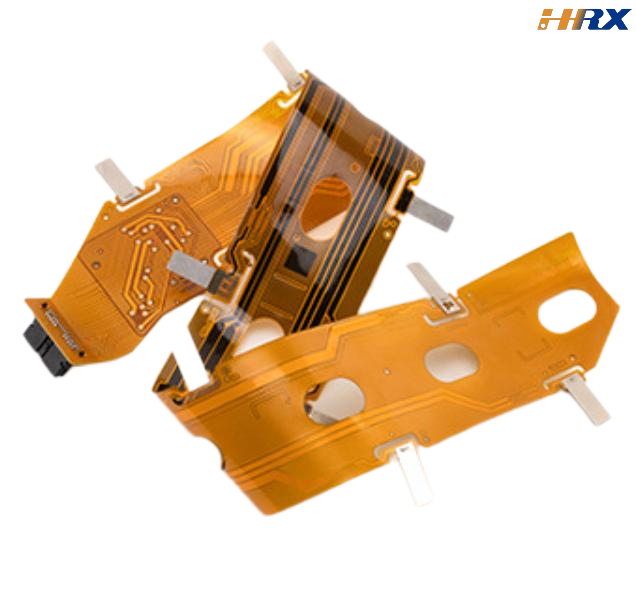

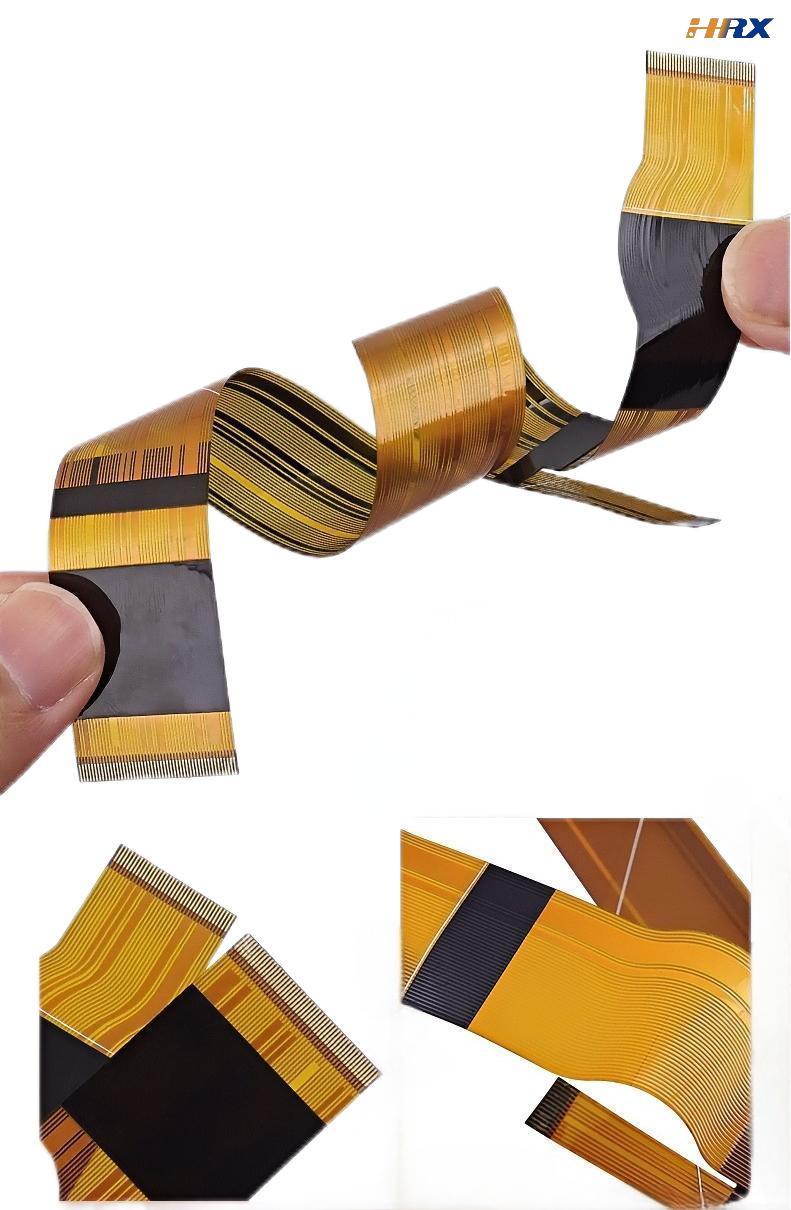

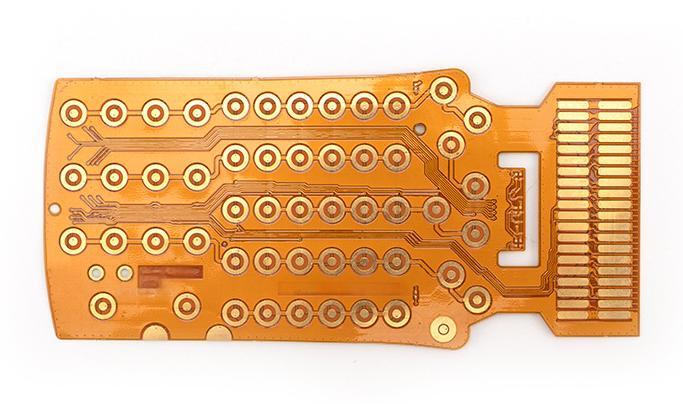

In the ever - evolving realm of electronics manufacturing, Flexible Printed Circuits (FPCs) have become an indispensable linchpin. Their ability to facilitate the creation of streamlined, compact, and high - performance electronic devices has solidified their position in the industry. As Shenzhen Huaruixin Electronics Co., Ltd., a seasoned and specialized provider in the design and production of FPCs, PCBs, and Rigid - Flex Printed Boards, we possess in - depth knowledge of the multifaceted factors that determine FPC pricing.

Material Costs: The Bedrock of FPC Pricing

Base Materials

The base material of an FPC is a fundamental element that exerts a profound influence on its pricing. Among the most commonly utilized base materials, polyimide and polyester stand out. Polyimide, renowned for its exceptional thermal stability, remarkable high - temperature resistance, and robust chemical durability, is the preferred choice for high - end applications, including aerospace and medical devices. However, its superior performance attributes come at a premium cost compared to polyester. Polyester, conversely, offers a more cost - effective solution and is well - suited for less exacting applications, such as consumer electronics with relatively lower temperature requirements. Additionally, the thickness of the base material plays a crucial role; thinner materials typically entail higher manufacturing and processing costs, thereby augmenting the overall price.

Conductive Materials

Copper remains the dominant conductive material in FPCs. The quality and thickness of the copper foil employed can vary significantly. High - purity electrolytic copper foils, which provide unparalleled electrical conductivity and reliability, command a higher price compared to lower - grade alternatives. Moreover, the thickness of the copper layer has a direct impact on cost. Thicker copper layers are indispensable for applications with elevated current - carrying capacities, but they not only increase material expenses but also heighten the complexity of subsequent manufacturing processes, further influencing the final price.

Adhesives and Dielectrics

Adhesives serve the critical function of bonding different layers of the FPC together, and their quality and type can significantly impact both the performance and cost. High - performance adhesives with exceptional bonding strength and excellent thermal stability are more costly. Dielectric materials, which act as insulators for the conductive traces, also contribute to the overall cost. Materials with superior dielectric properties, such as low dielectric constants and low dissipation factors, are often more expensive but are essential for high - frequency applications where signal integrity is of utmost importance.

Process Costs: The Influence of Manufacturing Complexity

Design Complexity

The design of an FPC is a pivotal determinant of its cost. Simple designs featuring fewer layers, less complex routing, and standard shapes are generally more affordable to produce. In contrast, complex multi - layer FPCs with elaborate circuit patterns, fine - pitch traces, and high - density interconnects (HDIs) demand the use of advanced design techniques and sophisticated software. The time and specialized expertise required to design such intricate FPCs contribute to an increase in the overall cost. Furthermore, custom designs tailored to specific customer requirements often necessitate additional engineering efforts, further driving up the price.

Manufacturing Processes

Photolithography

Photolithography is a cornerstone process in FPC manufacturing, responsible for transferring the circuit pattern onto the base material. The precision of the photolithography equipment and the quality of the photoresist utilized are key determinants of cost. Advanced photolithography techniques capable of achieving ultra - fine line widths and high - resolution patterns require the use of more expensive equipment and higher - quality consumables, thereby escalating the process cost.

Etching

The etching process is employed to remove the unwanted copper from the FPC, leaving behind the desired circuit pattern. The choice of etching method, whether wet etching or dry etching, along with the chemicals used, significantly impacts the cost. Wet etching, although more commonly used due to its relatively lower cost, may require additional steps for waste treatment, which adds to the overall cost. Dry etching, which offers enhanced precision and control, is more expensive due to the specialized equipment and gases involved.

Plating

Plating processes, including electroless plating and electroplating, are utilized to deposit additional layers on the FPC, such as gold or nickel - gold, to enhance conductivity and corrosion resistance. The cost of plating is contingent upon the type of metal used, the thickness of the plating layer, and the complexity of the plating process. Precious metals like gold are inherently costly, and the need for precise control over the plating thickness further contributes to the process cost.

Assembly

The assembly of components onto the FPC represents another cost - intensive aspect of production. Automated assembly using pick - and - place machines offers greater efficiency but necessitates a significant investment in expensive equipment and programming. Manual assembly, while suitable for low - volume production, is highly labor - intensive and time - consuming, resulting in increased labor costs. The complexity of the components being assembled, such as miniature surface - mount devices (SMDs) or high - pin - count integrated circuits (ICs), also has a substantial impact on the assembly cost.

Quality Control and Testing: Ensuring Reliability at a Cost

Quality control is of paramount importance in FPC manufacturing to guarantee the reliability and performance of the final product. Rigorous testing procedures, encompassing electrical testing, visual inspection, and environmental testing, are conducted at various stages of production. The cost of testing equipment, trained personnel, and the time dedicated to testing all contribute to the overall price of the FPC. Advanced testing methods, such as in - circuit testing (ICT) and flying probe testing, which are capable of detecting even the most minute defects, are more expensive but are essential for ensuring the production of high - quality FPCs.

At Shenzhen Huaruixin Electronics Co., Ltd., we are unwaveringly committed to delivering top - quality FPCs, PCBs, and Rigid - Flex Printed Boards at highly competitive prices. By leveraging our extensive expertise in material selection, state - of - the - art manufacturing processes, and stringent quality control measures, we strive to offer cost - effective solutions without compromising on performance. If you have any requirements or projects related to FPCs, PCBs, or Rigid - Flex Printed Boards, we invite you to visit our website at www.hrxfpc.com for more information or contact us via email at sales@hrxfpc.com. We also wholeheartedly welcome industry peers, new and old friends, to engage in exchanges and learning, as we firmly believe that collaboration and knowledge - sharing are the driving forces behind innovation in the electronics manufacturing industry.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP