Search

Common Circuit Effects in FPC Flexible Boards and Their Impact

- Apr 26,2025

-

Share

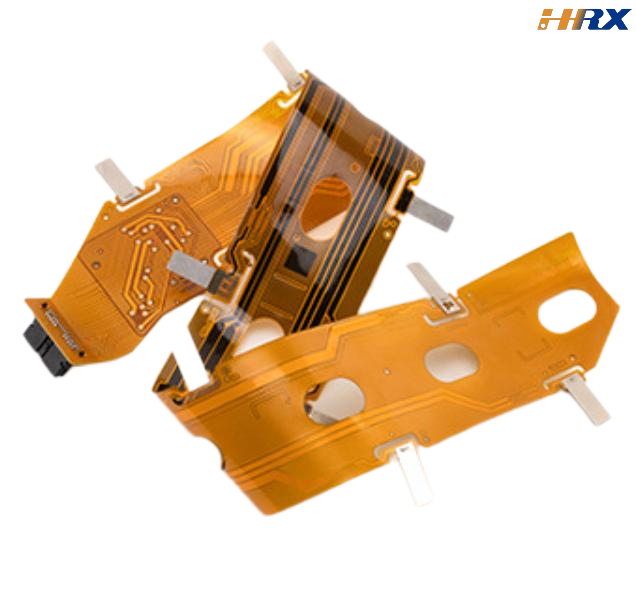

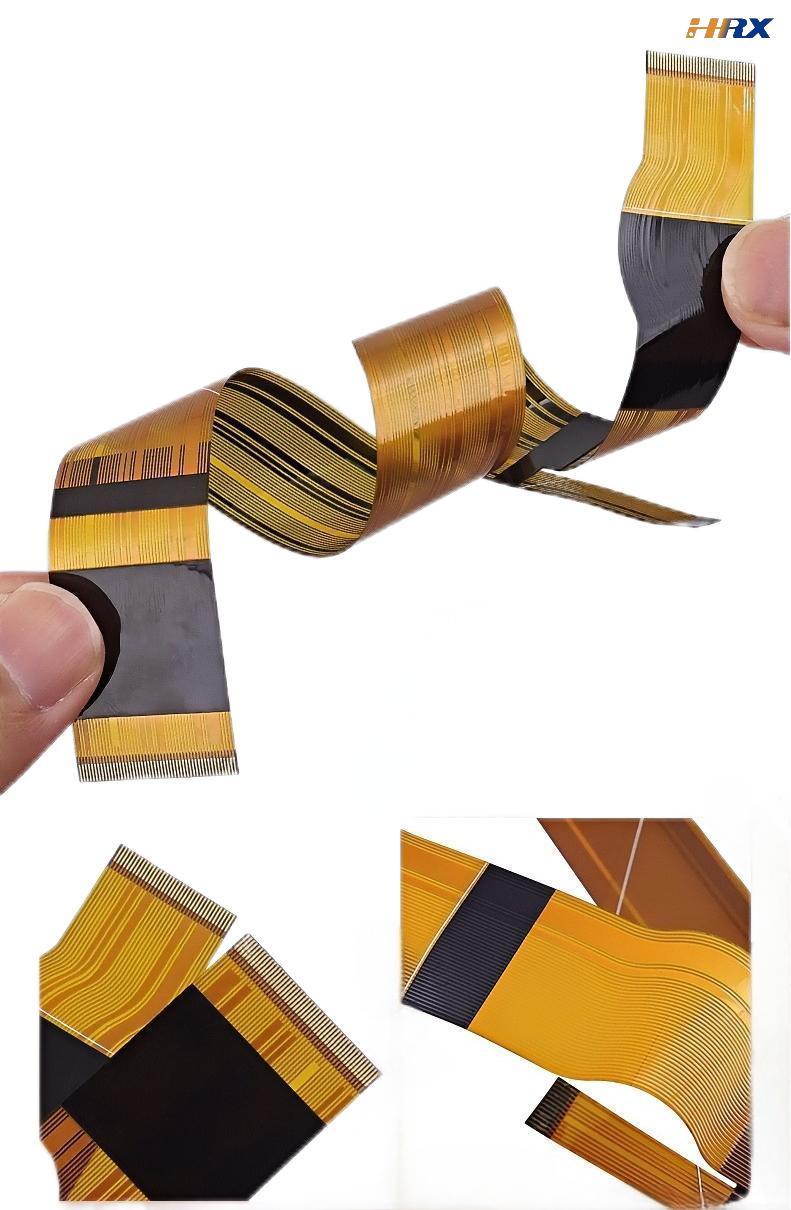

In the rapidly evolving landscape of modern electronics, Flexible Printed Circuits (FPCs) have become an indispensable cornerstone for advanced electronic systems, especially in applications requiring Flexible Interconnect Solutions. As a leading provider in the industry, Shenzhen Huaruixin Electronics Co., Ltd., renowned for its expertise in the design and production of FPCs, PCBs, and Rigid - Flex Printed Boards, deeply understands the critical role of various circuit effects in determining the performance and reliability of FPCs. This blog aims to dissect the most prevalent circuit effects in FPC soft boards, elucidate their underlying principles, and analyze their far - reaching impacts on FPC performance, while also highlighting our company’s innovative approaches to mitigate these effects.

1. Electromagnetic Effect

Principle

The electromagnetic phenomenon in FPCs encompasses two intertwined aspects: electromagnetic interference (EMI) and electromagnetic compatibility (EMC). In high - density FPC designs, when electrical current traverses the conductors, it generates an electromagnetic field in accordance with Ampere’s law. This generated field has the potential to interfere with adjacent electronic components, leading to signal degradation, data corruption, and even system failures. Conversely, EMC pertains to the ability of FPCs to function reliably in the presence of external electromagnetic disturbances without compromising their operational integrity. In the context of High - density Interconnect (HDI) FPCs, where conductor traces are closely packed, the risk of EMI is significantly elevated due to increased electromagnetic coupling.

Impact on FPC Performance

EMI poses a substantial threat to the performance of FPCs, particularly in high - speed data transmission scenarios. Crosstalk, a manifestation of EMI, occurs when the electromagnetic fields of neighboring signal traces on the FPC couple with each other. This coupling injects unwanted noise into the affected signals, causing signal distortion, increased bit - error rates, and reduced data transfer bandwidth. For applications such as high - speed serial interfaces in smartphones and tablets, where precise signal integrity is paramount, EMI - induced crosstalk can severely hamper device performance. At Shenzhen Huaruixin Electronics Co., Ltd., we implement state - of - the - art shielding techniques, including the application of conductive polymers and metallic shielding meshes, to contain electromagnetic fields and enhance the EMC compliance of our FPC products. Our commitment to EMC testing and certification ensures that our FPCs meet the stringent electromagnetic compatibility standards of global markets.

2. Thermal Effect

Principle

The thermal effect in FPCs is rooted in the fundamental principle of electrical resistance. When current flows through the conductors of an FPC, power dissipation occurs due to the inherent resistance of the conductive materials, as described by Joule’s law (\(P = I^{2}R\)). This dissipated power is converted into heat, which accumulates within the FPC layers. The rate of heat dissipation depends on the thermal conductivity of the FPC materials, including the dielectric layers and the conductive traces. In multi - layer FPC designs, the thermal management becomes more complex due to the presence of different materials with varying coefficients of thermal expansion (CTE).

Impact on FPC Performance

Excessive heat generation in FPCs can have detrimental consequences for both the mechanical and electrical properties of the circuit. Thermally induced expansion of the FPC materials can lead to delamination between layers, especially when there is a significant mismatch in CTE values. This delamination not only weakens the structural integrity of the FPC but also disrupts the electrical connections, potentially causing open circuits or short circuits. From an electrical perspective, high temperatures can increase the resistance of conductors, leading to voltage drops and power losses in the circuit. In high - power applications, such as battery - charging circuits in electric vehicles, effective thermal management is crucial to ensure the safe and reliable operation of FPCs. Our company utilizes advanced thermal simulation tools during the design phase to optimize conductor layouts, increase heat - dissipation areas, and select materials with high thermal conductivity. Additionally, we incorporate thermal vias and heat - spreading layers in our FPC designs to enhance heat dissipation efficiency, adhering to the best practices in FPC thermal management.

3. Capacitive and Inductive Effects

Principle

Capacitive and inductive effects in FPCs are a result of the close proximity of conductors and the changing electrical and magnetic fields. Capacitance is formed between adjacent conductors on the FPC, creating a charge - storage mechanism. When the voltage across these conductors changes, electrical charge is transferred between them, leading to capacitive coupling. Inductance, on the other hand, is associated with the magnetic fields generated by current - carrying conductors. According to Faraday’s law of electromagnetic induction, a change in the current of one conductor induces a voltage in nearby conductors, resulting in inductive coupling. In high - frequency FPC applications, these capacitive and inductive couplings become more pronounced, affecting the signal propagation characteristics.

Impact on FPC Performance

Capacitive and inductive couplings can severely degrade the signal integrity of FPCs. Capacitive coupling can introduce phase shifts and attenuation in high - frequency signals, distorting the waveform and reducing the signal - to - noise ratio. Inductive coupling, particularly in high - current or high - frequency circuits, can cause crosstalk, similar to EMI - induced crosstalk. These effects can lead to data transmission errors and reduced system performance. To address these challenges, our engineers at Shenzhen Huaruixin Electronics Co., Ltd. employ advanced routing algorithms and conductor - spacing optimization techniques during the FPC design process. By carefully controlling the physical layout of conductors, we minimize capacitive and inductive couplings, ensuring reliable signal transmission even in the most demanding high - frequency applications. Our expertise in impedance matching and signal - integrity analysis further enhances the performance of our FPC products, making them suitable for a wide range of high - tech applications.

In conclusion, a comprehensive understanding of the various circuit effects in FPC soft boards is the key to developing high - performance, reliable FPC solutions. As a trusted partner in the FPC manufacturing industry, Shenzhen Huaruixin Electronics Co., Ltd. is dedicated to leveraging our extensive knowledge and cutting - edge manufacturing techniques to overcome these challenges. Whether you are in need of custom FPC designs for consumer electronics, automotive applications, or medical devices, our team is ready to provide tailored solutions that meet your specific requirements. Visit our website at www.hrxfpc.com to explore our wide range of products and services, or contact us via email at sales@hrxfpc.com for detailed inquiries. We also invite industry professionals and enthusiasts to engage in technical discussions and knowledge sharing, as we strive to drive innovation and excellence in the field of printed circuit boards.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP