Search

Flexible Printed Circuits (FPCs): The Hidden Tech Revolution in Smart Devices

- Apr 26,2025

-

Share

In the rapidly evolving landscape of smart devices, every component plays a pivotal role. Among these, Flexible Printed Circuits (FPCs) are emerging as a transformative technology, poised to reshape the electronics industry. As Shenzhen Huaruixin Electronics Co., Ltd., a leading manufacturer specializing in FPC, PCB, and Rigid - Flex Printed Boards, we are at the vanguard of witnessing and driving this technological paradigm shift.

The Advantages of FPCs in Smart Devices

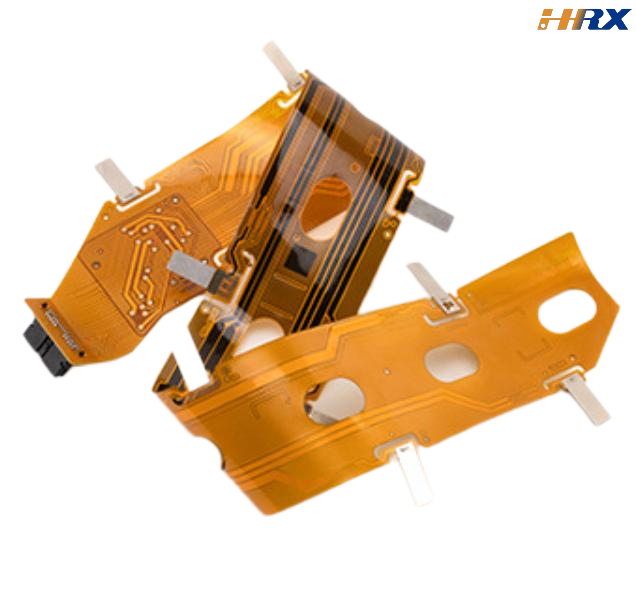

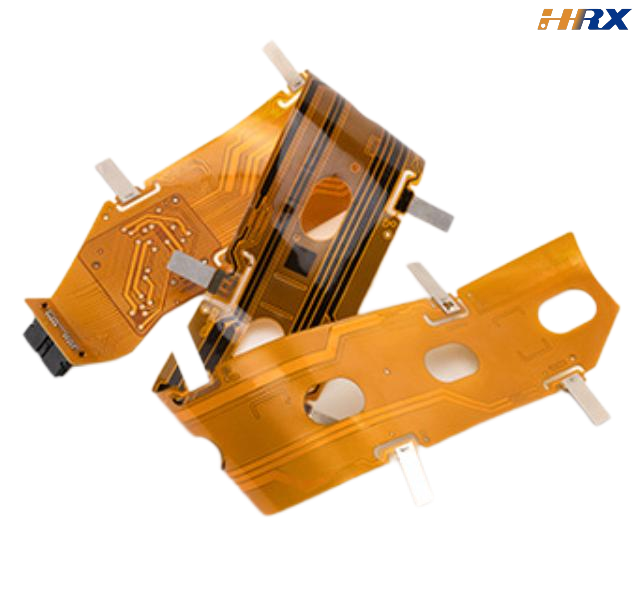

High - Density Integration

One of the most remarkable advantages of FPCs lies in their high - density integration capabilities. In smart devices where spatial constraints are paramount, FPCs leverage High - Density Interconnect (HDI) technology to pack a multitude of circuit connections into a minimal footprint. With their elevated wiring density, FPCs enable the seamless integration of multiple functional components, significantly reducing the reliance on traditional connectors. This not only conserves valuable space but also enhances signal integrity and reliability. For instance, in smartwatches, FPCs utilize Surface Mount Technology (SMT) to efficiently connect various sensors, displays, and communication modules, contributing to the device's sleek and compact design.

Automated and Precision Assembly

Automation is a defining trend in contemporary manufacturing, and FPCs are ideally suited to this paradigm. As pre - fabricated modules, FPCs are highly compatible with robotic assembly systems, facilitating easy installation by robotic arms. This automated assembly process significantly bolsters production efficiency, in stark contrast to traditional wire harnesses, where up to 95% of the assembly process may rely on manual wiring in some cases. The precision of FPCs, underpinned by advanced manufacturing techniques such as Laser Direct Imaging (LDI), ensures accurate and consistent connections, minimizing assembly errors. In the automotive electronics sector, where large - scale production demands high - speed and precise assembly, FPCs are increasingly adopted. For example, in automotive door wiring applications, FPCs can be accurately positioned to connect diverse components, streamlining the manufacturing workflow and enhancing overall production quality.

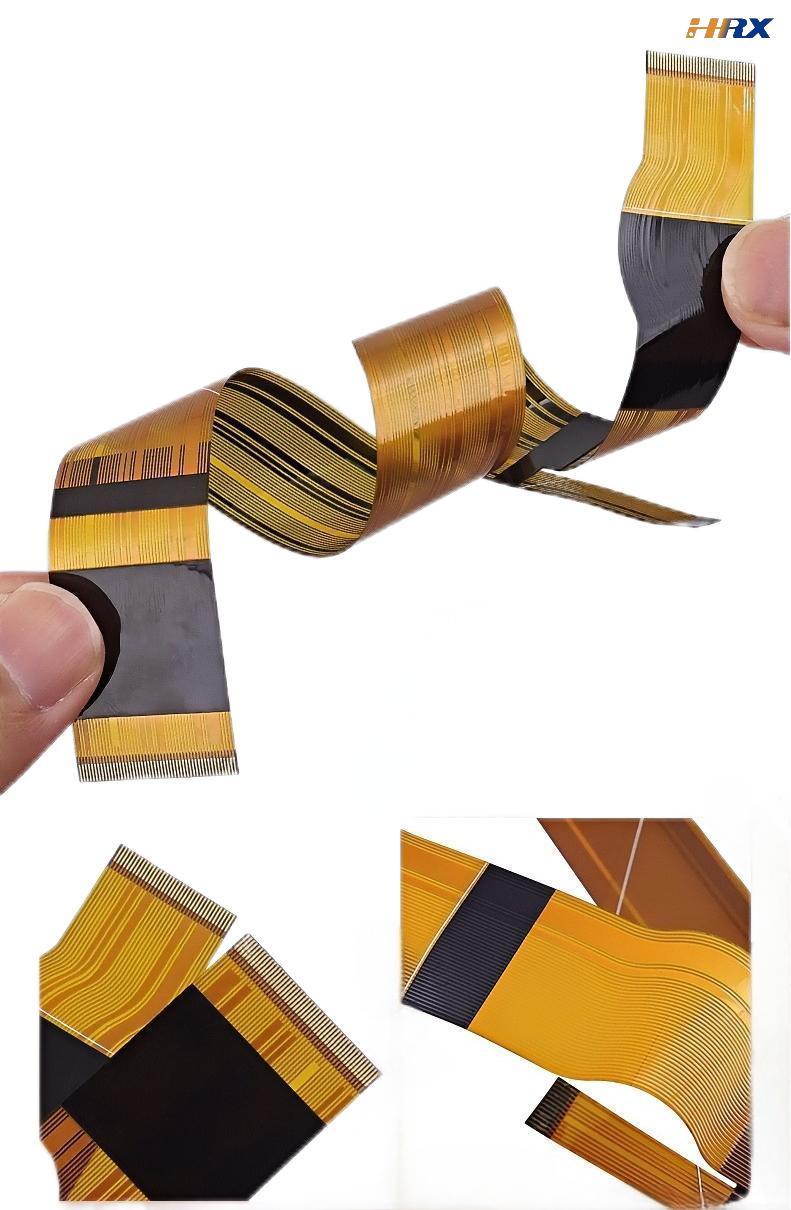

Ultra - Thin and Flexible Design

FPCs are characterized by their ultra - thin profile and exceptional flexibility, offering a distinct advantage in smart device design. With a thickness often measured in mere micrometers, FPCs can be bent, folded, or twisted to conform to complex geometries and confined spaces. This flexibility unlocks new possibilities for innovative and space - efficient designs. In smartphones, FPCs are routed around critical components such as batteries and cameras, optimizing the utilization of available space and contributing to the device's slim form factor. Wearable devices, like fitness trackers, benefit even more from the flexibility of FPCs. These devices require a comfortable fit that conforms to the body's contours, and FPCs enable the seamless integration of electronics into the wearable design, enhancing both functionality and user comfort.

Lightweight Construction

The lightweight nature of FPCs is another significant advantage. In an era where portability is highly prized, reducing the weight of smart devices is crucial for enhancing user experience and extending battery life. Compared to traditional rigid circuit boards, FPCs offer substantial weight savings, facilitating the miniaturization and lightweighting of electronic products. This not only improves the device's portability but also has a positive impact on energy consumption. Lighter devices require less power to operate, potentially extending battery runtime. In tablet computers, the adoption of FPCs contributes to a more lightweight and portable design, making them more convenient for users on the move.

FPCs vs. Traditional Wire Harnesses: The Changing Tides

Traditional wire harnesses have long been the standard for connecting components in electronic devices. However, they are encumbered by several limitations. Wire harnesses are bulkier, heavier, and demand a significant amount of space for routing. Additionally, the manual assembly process is time - consuming, labor - intensive, and prone to errors.

FPCs, in contrast, present a compelling alternative. As previously discussed, their high - density integration, automated assembly, and lightweight construction make them far more efficient. In the automotive industry, we are witnessing a notable shift towards FPCs. For example, Tesla has achieved remarkable reductions in vehicle wiring complexity by implementing FPCs. In the Model Y, the number of door wire harnesses was decreased from 25 to 8, and the total wire harness length was slashed from 1.5 kilometers to a mere 100 meters, resulting in an 80% weight reduction. This not only simplifies the manufacturing process but also enhances the reliability and performance of the vehicle's electrical system.

Market Prospects of FPCs

The FPC market is experiencing robust growth and shows no signs of abating. With the continuous expansion of the smart device market, encompassing smartphones, wearables, tablets, and automotive electronics, the demand for FPCs is projected to grow exponentially.

In the consumer electronics segment, the ongoing trend towards thinner, lighter, and feature - rich devices is a major driver of FPC adoption. As consumers increasingly demand smaller yet more powerful smartphones and wearables, manufacturers are turning to FPCs to meet these exacting design requirements.

The automotive industry is also a significant growth engine for FPCs. With the accelerating electrification and automation of vehicles, there is a burgeoning need for reliable and space - saving wiring solutions. FPCs, with their ability to handle high - voltage and high - speed data transmission while reducing vehicle weight, are well - positioned to meet these demands.

Furthermore, emerging markets such as the Internet of Things (IoT) and medical devices present substantial opportunities for FPCs. In IoT devices, which typically require low - power consumption and compact designs, FPCs' lightweight and flexible attributes make them an ideal choice. In the medical device sector, where reliability and miniaturization are of utmost importance, FPCs enable the development of more advanced and compact diagnostic and treatment equipment.

At Shenzhen Huaruixin Electronics Co., Ltd., we are dedicated to leveraging our extensive expertise in FPC manufacturing to meet the surging market demand. Our state - of - the - art manufacturing facilities, combined with a highly skilled team, enable us to produce FPCs of the highest quality that adhere to the strictest industry standards. We are excited about the future of FPCs in smart devices and look forward to playing an instrumental role in driving continued innovation in this dynamic field.

In conclusion, FPCs are not merely hidden components in smart devices; they are powerful enablers of technological innovation. Their myriad advantages over traditional wire harnesses position them as the technology of choice for the next generation of smart devices. As the market continues to expand, we anticipate FPCs playing an even more prominent role in shaping the future of the electronics industry.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP