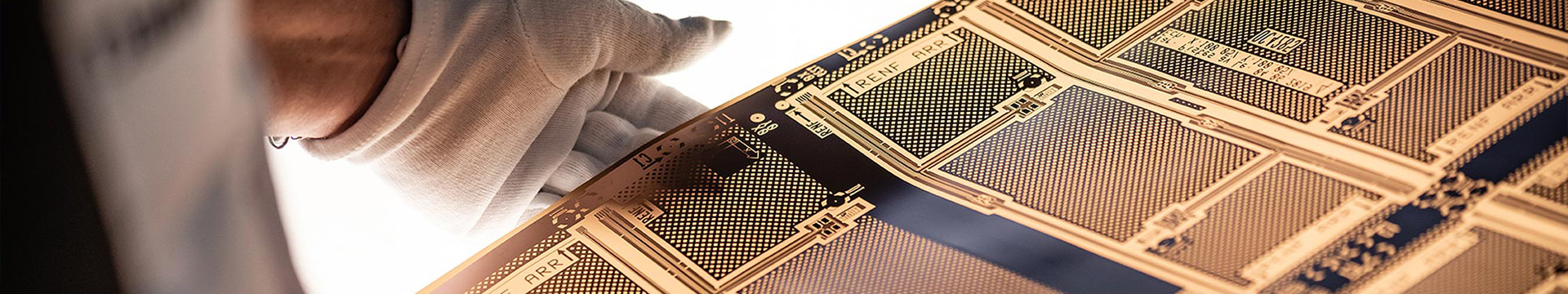

Welcome to our FPC Capabilities section, where we highlight our expertise in Flexible Printed Circuits. As technology advances, the demand for versatile and high-performance FPC solutions grows. Our production capabilities are designed to meet these demands with precision and innovation. In this section, you’ll find a detailed table outlining our FPC production specifications and features, showcasing our commitment to exceptional performance and flexibility.

Our state-of-the-art manufacturing processes and technology ensure that our FPC solutions meet your specific needs across various industries, from consumer electronics to automotive. Review the information below to see how our capabilities can support your projects and drive your success.

| Flex PCB Technical Capabilities | |

| ITEM | Standard Capabilities |

| FPC Layer | 1-16L |

| FPC Material | |

| Base Material | PI (12.5um, 25um, 50um, 75um, 100um) |

| Copper Type | RA Copper: 12um, 18um, 35um, 70um |

| ED Copper: 12um, 18um, 35um, 70um | |

| PI Coverlay | 12.5um, 25um, 50um, 75um |

| Adhesive | PSA Adhesive: 50um-100um (3M467, 3M468, 3M9077, Tesa 8853, etc.) |

| Stiffeners | PI Stiffener: 12.5/25/50/75/100/125/150/200/250 (um) |

| FR4 Stiffener: 0.1mm-2.0mm | |

| SUS Stiffener: 0.1mm-0.5mm | |

| Aluminum Stiffener: 0.1mm-0.5mm | |

| EMI shielding film | TSS100, TSS200, HCF-6000G, PC800, etc. |

| Board Size & Thickness | |

| Biggest Board Size | 1L:500mm*850mm; 250mm*2000mm; |

| 2L:500mm*850mm; 250mm*1200mm | |

| >2L:500mm*500mm; 250mm*1000mm (to be confirmed) | |

| Thinnest Board Thickness | 0.05mm |

| Thickness Tolerance | 0.05mm~0.24mm: ±0.03mm |

| 0.25mm~0.47mm: ±0.05mm | |

| Drill | |

| Minimum Hole Size | 0.1 mm |

| Holes Size Tolerance | PTH±0.075mm, NPTH±0.05mm |

| Holes Posistion Tolerance | ±0.05 mm |

| Minimum vias Pad Size | 0.25mm |

| Minimum Annular Ring Size | 0.075mm |

| Blind/Buried Vias | Yes |

| Copper Tracks and Plating | |

| Minimum Track Width/Space (35um Copper) | 0.1mm/0.1mm |

| Minimum Track Width/Space (18um Copper) | 0.07mm/0.07mm |

| Minimum Track Width/Space (12um Copper) | 0.05mm/0.05mm |

| Track Width Tolerance | 20% |

| Tracks/Pads Position Tolerance | ≥0.06 mm |

| Tracks/Pads To Board Edge | ≥0.15 mm |

| Golden Finger Pitch Tolerance | Pitch:10~20mm : ± 0.03mm |

| Pitch:20~50mm : ± 0.05mm | |

| Copper Plating Thickness | 8-20um |

| Hole Copper Thickness | 8-30um |

| Minimum Copper Thickness for Hollow Out FPC | 35um |

| Surface Finish | |

| ENIG | AU: 1-3u" Thickness |

| NI: 40-120u" Thickness | |

| Hard Gold Plating | AU: 1-50u” Thickness |

| NI: 80-320u" Thickness | |

| Immersion Silver | Ag: 6-12u" Thickness |

| OSP | 8-20u" Thickness |

| Immersion Tin | SN: 10-60u" Thickness |

| Tin Plating | SN: 5-30um Thickness |

| ENEPIG | Au:1-4u" Thickness |

| NI: 120-200u" Thickness | |

| Pd:1-6u" Thickness | |

| Coverlay | |

| Coverlay Opening Size Tolerance | ±0.1 mm |

| Minimum Drilling Size on Coverlay Opening | 0.45mm |

| Minimum Square Size on Coverlay Opening | 0.5mm*0.5mm |

| Coverlay Opening Position Tolerance | ±0.1 mm |

| Coverlay Align Tolerance | ±0.1 mm |

| Excessive Glue | ≤0.15 mm |

| Minimum Area of Excessive Glue | ≤20% Pads Area |

| Solder Mask and Silkscreen | |

| Solder Mask Thickness | 15um +/-5um |

| Solder Mask Tolerance For Opening Size | +/-0.05mm |

| Solder Mask Tolerance For Opening Position | 0.1mm |

| Minimum Silkscreen line width | 0.13mm |

| Minimum Silkscreen Gap | 0.2mm |

| Minimum Silkscreen Position Tolerance | +/-0.3mm |

| Minimum Silkscreen height | 0.8mm |

| Minimum Solder Mask Bridge | 0.13mm |

| Board Outline & Stiffeners | |

| Board Outline Tolerance with Steel Die | ±0.1 mm |

| Board Outline Tolerance with Knife Die | ±0.2 mm |

| Minimum Gap Between Drilling and Board Edge | ≥0.5 mm |

| PSA Position Tolerance | ±0.2 mm |

| Stiffeners Position Tolerance | ±0.2 mm |

| FPC E-Test | |

| Test Voltage | 10-50V |

| Insulation Test Impedance | ≥10MΩ |

| Conduction Test Impedance | ≤50Ω |

| Impedance Tolerance | 10% |

| FPC Physical Property | |

| Solderability Test | 245±5℃, 3 Seconds For One Time, soldering Area>95% |

| Thermal Shock Test | 288±5℃, 10 Seconds Per 3 Times, no Delamination and No Bubbles |

| FCCL Peel Strength | ≥0.8kgf/㎠ (1cm width sample) |

| Coverlay Peel Strength | ≥0.8kgf/㎠ (1cm width sample) |

| Stiffeners Peel Strength | 0.15 N/mm (Hot-Press Adhesive) |

| 0.49 N/mm (PSA Adhesive) | |

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP