Search

Why are Rigid-Flex PCBs Pricier Than Standard PCB

- Mar 06,2023

-

Share

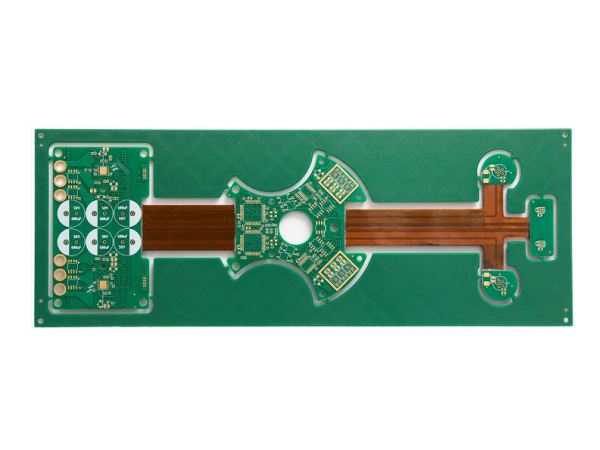

Rigid-flex PCBs have gained popularity in various industries due to their versatility and space-saving design. However, one aspect that often raises eyebrows is their higher cost compared to traditional rigid or flexible PCBs. In this article, we'll explore the factors contributing to the price disparity between rigid-flex PCBs and standard PCBs.

1. Complex Manufacturing Process:

One of the primary reasons for the higher cost of rigid-flex PCBs is the complexity of their manufacturing process. Unlike standard PCBs, which are typically fabricated in a single step, rigid-flex PCBs involve multiple intricate processes, including layer alignment, bonding, and lamination of flexible and rigid substrates. These additional steps require specialized equipment and expertise, driving up production costs.

2. Material Selection:

Rigid-flex PCBs utilize a combination of flexible and rigid materials, such as polyimide and FR-4, to achieve their unique structure. These materials are often more expensive than those used in standard PCBs, adding to the overall cost of manufacturing. Furthermore, the need for high-quality materials to ensure reliability and durability further contributes to the price difference.

3. Design Complexity and Customization:

Rigid-flex PCBs are often custom-designed to meet specific application requirements, resulting in higher design complexity and customization compared to standard PCBs. Designing a rigid-flex PCB involves considerations such as bend radius, layer stack-up, and routing constraints, which require advanced engineering expertise and specialized software tools. The additional time and resources invested in customizing the design contribute to the higher cost.

4. Quality Assurance and Testing:

Ensuring the reliability and performance of rigid-flex PCBs requires rigorous quality assurance and testing procedures. Due to their complex structure and the potential for mechanical stress during operation, thorough testing is essential to identify any defects or weaknesses. This includes electrical testing, impedance control, and mechanical reliability testing, all of which add to the overall cost of production.

5. Limited Production Capacity:

The specialized equipment and expertise required for manufacturing rigid-flex PCBs often result in limited production capacity compared to standard PCBs. This limited capacity can lead to higher setup costs and longer lead times, further contributing to the higher cost of rigid-flex PCBs.

While the higher cost of rigid-flex PCBs may initially seem prohibitive, it is essential to recognize the value they offer in terms of space savings, reliability, and design flexibility. By understanding the factors driving the price difference, designers and manufacturers can make informed decisions and leverage the unique capabilities of rigid-flex PCBs to create innovative and reliable electronic devices.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP