Search

When Are Rigid-Flex PCBs the Best Fit for Your Project?

- Jul 28,2023

-

Share

The world of electronics is continuously evolving, and with it, the need for more versatile and reliable circuit boards. Rigid-flex circuit boards have emerged as a solution that combines the best of both rigid and flexible PCBs, offering unique advantages for a wide range of applications. In this blog, we will delve into four key aspects of rigid-flex circuit boards: understanding their structure, their applications, their advantages, and when to choose them for your project.

1. Understanding Rigid-Flex Circuit Boards

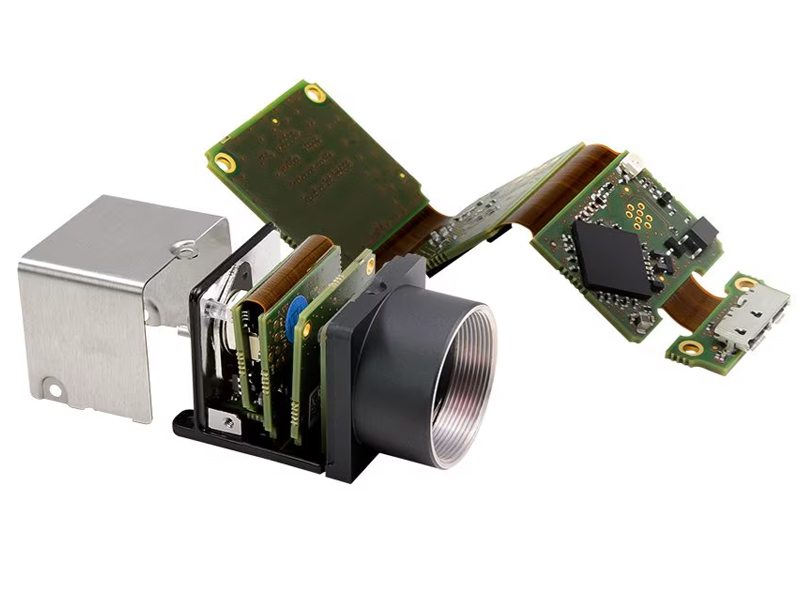

Rigid-flex circuit boards are a hybrid of rigid and flexible PCBs. They consist of multiple layers of flexible circuit substrates, often made of polyimide, which are laminated together with rigid board sections, typically made of FR-4. This combination allows for the creation of a unified board that can be bent or folded while maintaining structural integrity and providing reliable electrical connections.

The design and manufacturing process of rigid-flex PCBs are intricate and require careful consideration of several factors, including the precise alignment of layers, the use of specialized adhesives and coverlays, and rigorous quality control measures. The flexible parts of the PCB can bend and twist, which makes them ideal for applications where space is constrained or the board needs to fit into a non-flat shape.

2. Rigid-Flex PCB Applications

Rigid-flex PCBs are used in a wide variety of applications due to their versatility and reliability. Some of the key areas where they are employed include:

Aerospace and Defense: In these industries, the ability to withstand harsh conditions and vibrations is crucial. Rigid-flex PCBs are used in avionics, satellites, and military equipment where reliability and durability are paramount.

Medical Devices: The compact and flexible nature of rigid-flex PCBs makes them ideal for medical devices such as pacemakers, imaging equipment, and wearable health monitors. These boards help in reducing the size and weight of devices while maintaining high performance.

Consumer Electronics: Smartphones, tablets, and wearable devices benefit from the space-saving and flexible design of rigid-flex PCBs. They enable more compact and innovative product designs.

Automotive: Modern vehicles incorporate numerous electronic systems for safety, navigation, and entertainment. Rigid-flex PCBs are used in infotainment systems, sensor modules, and engine control units due to their robustness and flexibility.

3. Advantages of Rigid-Flex Circuit Boards

Rigid-flex PCBs offer several advantages over traditional rigid or flexible PCBs:

Space and Weight Savings: By integrating rigid and flexible parts, these PCBs reduce the need for connectors and cables, leading to significant space and weight savings. This is particularly beneficial in compact devices and applications where weight is a critical factor.

Enhanced Reliability: The elimination of connectors and cables reduces potential failure points, enhancing the overall reliability of the circuit. Rigid-flex PCBs can withstand vibrations and mechanical stresses better than traditional PCBs.

Improved Signal Integrity: With fewer interconnections, the risk of signal loss or interference is minimized. This results in better signal integrity and performance, especially in high-frequency applications.

Design Flexibility: Rigid-flex PCBs allow for more creative and compact designs. Engineers can design circuits that fit into unconventional shapes and spaces, opening up new possibilities for product development.

4. When to Choose Rigid-Flex Circuit Boards

Deciding when to use rigid-flex PCBs involves evaluating the specific requirements of your project:

Complex Geometries and Limited Space: If your design involves complex geometries or limited space, rigid-flex PCBs are an ideal choice. They can be bent and folded to fit into tight spaces without compromising performance.

High Reliability and Durability: For applications where reliability and durability are critical, such as aerospace, defense, and medical devices, rigid-flex PCBs provide a robust solution that can withstand harsh conditions.

Weight and Space Constraints: In industries like consumer electronics and automotive, where reducing weight and saving space are priorities, rigid-flex PCBs offer significant advantages by eliminating bulky connectors and cables.

Cost Considerations: While rigid-flex PCBs are generally more expensive to manufacture, their ability to combine multiple rigid and flexible circuits into a single board can reduce assembly costs and improve reliability, potentially offsetting the higher initial investment.

Rigid-flex circuit boards represent a significant advancement in PCB technology, offering unparalleled flexibility, reliability, and design versatility. Understanding their structure, applications, and advantages can help engineers and designers make informed decisions about when to incorporate them into their projects. While they come with higher manufacturing costs, the benefits they provide often justify the investment, especially in applications where space, weight, and reliability are critical factors. Whether you are developing cutting-edge consumer electronics or mission-critical aerospace systems, rigid-flex PCBs can provide the solution you need to meet your design challenges.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP