Search

Flexible Printed Circuit (FPC) Production Technology

- Apr 11,2025

-

Share

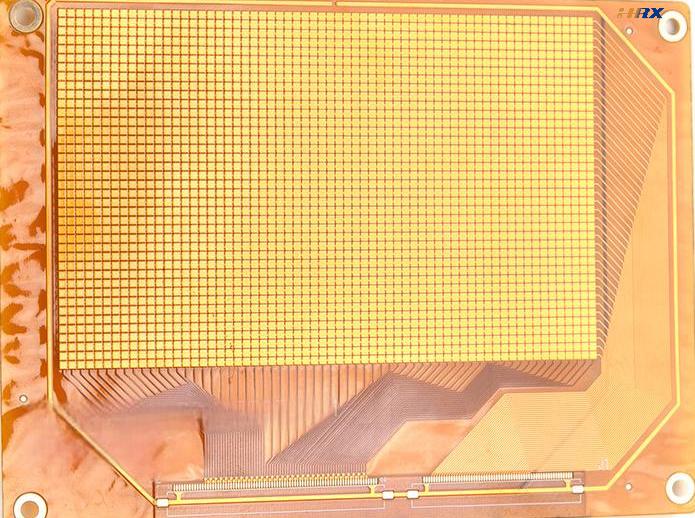

Shenzhen Huaruixin Electronics Co., Ltd. has firmly established itself as a leading force in the printed circuit board domain, with a strong focus on the design and production of Flexible Printed Circuits (FPCs), Printed Circuit Boards (PCBs), and Rigid - Flex Printed Boards. Their expertise in FPC production is particularly noteworthy, marked by the implementation of state - of - the - art technologies.

Advanced 10.8um Lithography Technology: A Game - Changer in FPC Production

The adoption of 10.8um advanced lithography technology represents a significant leap forward in FPC manufacturing. This cutting - edge technology allows for the creation of ultra - fine circuit patterns, significantly enhancing the integration density of FPCs. In the context of modern electronics, where miniaturization and high - performance are key, the ability to pack more components into a smaller footprint is invaluable.

High - density interconnect (HDI) is a crucial aspect here. The 10.8um lithography technology enables the realization of HDI FPCs, which are essential for applications such as high - end smartphones, wearables, and advanced medical devices. By achieving finer line widths and spaces, signal transmission becomes more efficient, reducing signal attenuation and crosstalk. This not only improves the overall performance of the FPC but also ensures reliable operation in high - speed data transfer scenarios.

Eliminating the Misaligned Hole Problem: Ensuring Precision and Reliability

One of the major challenges in FPC production has been the misaligned hole problem. At Shenzhen Huaruixin Electronics Co., Ltd., the advanced lithography process has effectively addressed this issue. In the FPC manufacturing process, misaligned holes can lead to problems during component assembly, such as poor soldering connections and mechanical instability.

Through strict process control and the use of high - precision equipment, the company ensures that holes are drilled accurately, maintaining tight tolerances. This not only improves the yield of the production process but also enhances the long - term reliability of the FPCs. For applications where reliability is of utmost importance, such as aerospace and automotive electronics, this attention to detail is crucial.

Production Experience and Best Practices

Over the years, Shenzhen Huaruixin Electronics Co., Ltd. has accumulated extensive experience in FPC production. One of the key lessons learned is the importance of material selection. The choice of base materials, such as polyimide films, can significantly impact the performance of the FPC. High - quality polyimide films with excellent thermal stability and mechanical properties are preferred for applications that require the FPC to withstand harsh environments.

Another critical aspect is the surface treatment of the FPC. Surface treatments like electroless nickel immersion gold (ENIG) or organic solderability preservative (OSP) are used to protect the copper traces and improve solderability. The company has developed optimized processes for these surface treatments to ensure consistent quality across all production batches.

Quality Control in FPC Production

Quality control is a cornerstone of Shenzhen Huaruixin Electronics Co., Ltd.'s FPC production. The company employs a comprehensive quality management system that includes in - line inspection at every stage of the production process. Automated optical inspection (AOI) systems are used to detect any defects in the circuit patterns, such as open circuits, short circuits, or missing components.

X - ray inspection is also utilized to ensure the integrity of through - hole connections and to detect any hidden defects. By implementing such rigorous quality control measures, the company can guarantee that its FPC products meet the highest industry standards.

Meeting the Demands of High - End Electronics

In today's fast - paced electronics market, high - end devices are constantly evolving, demanding ever - more sophisticated FPC solutions. Shenzhen Huaruixin Electronics Co., Ltd.'s technological prowess and production experience enable it to meet these demands head - on. Whether it's the need for high - density interconnects, high - speed signal transmission, or reliable operation in extreme conditions, the company's FPC products are designed to excel.

Get in Touch for Your FPC Needs

If you are in need of high - quality FPCs for your projects, whether it's for consumer electronics, industrial applications, or any other field, Shenzhen Huaruixin Electronics Co., Ltd. is your go - to partner. You can visit our website at www.hrxfpc.com to explore our comprehensive range of products and services. For any inquiries, feel free to send an email to sales@hrxfpc.com.

We also welcome industry professionals, new and old friends, to engage in technical exchanges and knowledge sharing. The world of FPC technology is constantly evolving, and through collaboration and learning, we can drive further innovation in this exciting field.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP