Search

What should we pay attention to EMI shield design to avoid the interfering?

- Oct 20,2023

-

Share

Electromagnetic interference (EMI) is a critical concern in electronic circuit design. Proper EMI shielding is essential to ensure that devices function correctly and do not interfere with one another. Below are some best practices to consider when designing EMI shields, aimed at minimizing interference and improving the overall performance of your circuit.

1. Maintain Signal Separation

Effective EMI shield design begins with keeping different types of signals separate. High-speed traces, such as clock signals, should be routed separately from low-speed signals to prevent interference. Similarly, analog signals should be isolated from digital signals. This separation helps to reduce crosstalk and signal degradation, ensuring that each type of signal operates within its intended parameters without being affected by others.

2. Minimize Return Path Lengths

Keeping return paths short is crucial in EMI design. Long return paths can act as antennas, picking up noise and emitting unwanted signals. By minimizing these paths, you reduce the likelihood of noise interference, helping to maintain signal integrity throughout the circuit.

3. Optimize Differential Pair Routing

Differential pairs should be routed as closely as possible. When differential traces are in close proximity, the coupling between them is enhanced. This increased coupling helps convert noise into common mode signals, which are less problematic for differential input stages. Proper routing of differential pairs is essential for maintaining high-speed signal integrity.

4. Use Vias with Caution

Vias are necessary for taking advantage of multi-layer PCB designs, but they come with their own set of challenges. Vias introduce additional inductance and capacitance, which can alter the signal's characteristic impedance and cause reflections. Designers should use vias judiciously, understanding their impact on the overall signal integrity.

5. Avoid Vias in Differential Traces

Whenever possible, avoid placing vias in differential traces, as they can disrupt the balance of the differential signal. If vias must be used, consider using an oval anti-pad shared by the two vias. This design reduces parasitic capacitance, minimizing its impact on the signal.

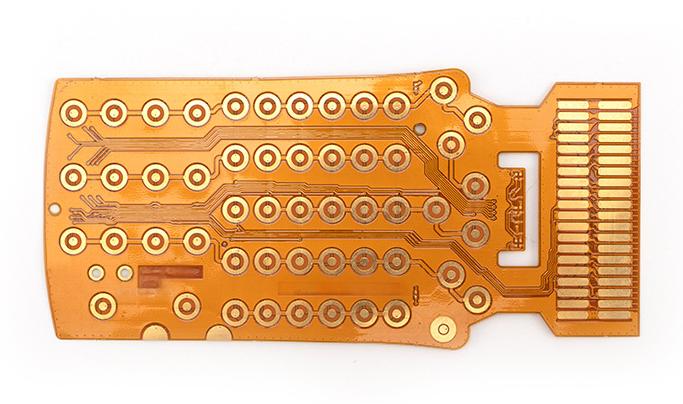

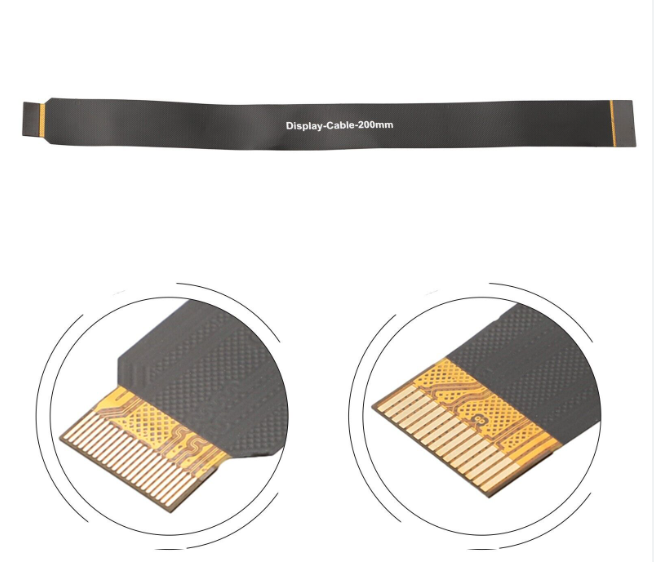

6. Opt for Dual-Sided or Multi-Layered FPC Designs

Single-sided Flexible Printed Circuit (FPC) EMI shields are often insufficient for effective interference protection. To achieve better shielding, consider designing dual-sided or multi-layered FPCs. These configurations provide better EMI suppression and enhance the overall robustness of the circuit.

7. Avoid Sharp Right-Angle Bends

Sharp right-angle bends in traces can increase capacitance in the corner region, altering the trace's characteristic impedance and leading to signal reflections. To mitigate this, use rounded or 45° angles instead of right angles. This design adjustment helps maintain consistent impedance and reduces the risk of signal reflection.

8. Ensure Proper Solder Mask Openings

For effective EMI shielding, the minimum solder mask opening should be more than 0.8mm. Additionally, ensure that the solder mask area is at least 0.2mm away from the traces. This distance helps prevent interference from the solder mask affecting the trace, maintaining the signal’s integrity.

Conclusion

Proper EMI shield design is a critical aspect of modern electronic circuit design. By following these best practices, designers can significantly reduce the risk of electromagnetic interference, ensuring that their devices operate reliably and efficiently. Whether it’s maintaining signal separation, optimizing differential pair routing, or avoiding sharp bends, attention to detail in EMI shield design can make a significant difference in the final product's performance.

Let’s talk! We’ll provide the perfect solution for you!

-

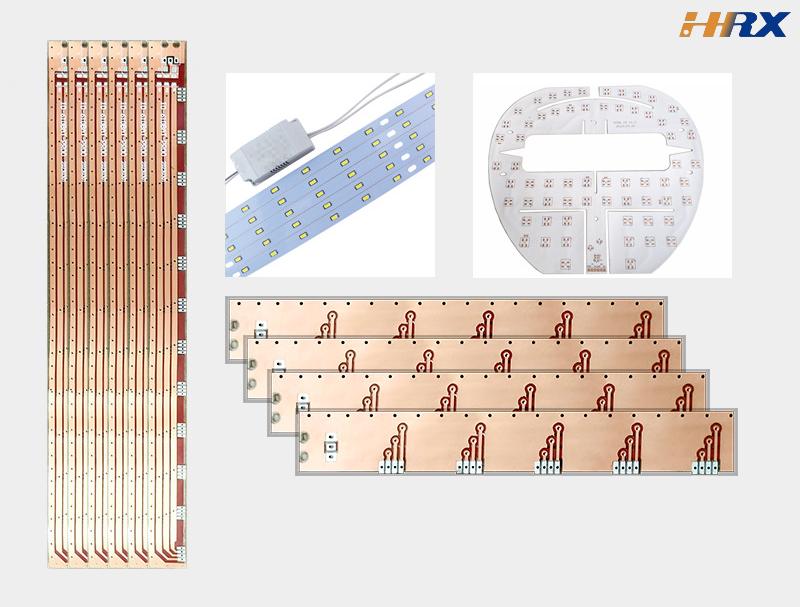

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP