Search

What Makes Rigid Flex PCBs More Expensive Than Other Circuit Boards?

- Aug 09,2023

-

Share

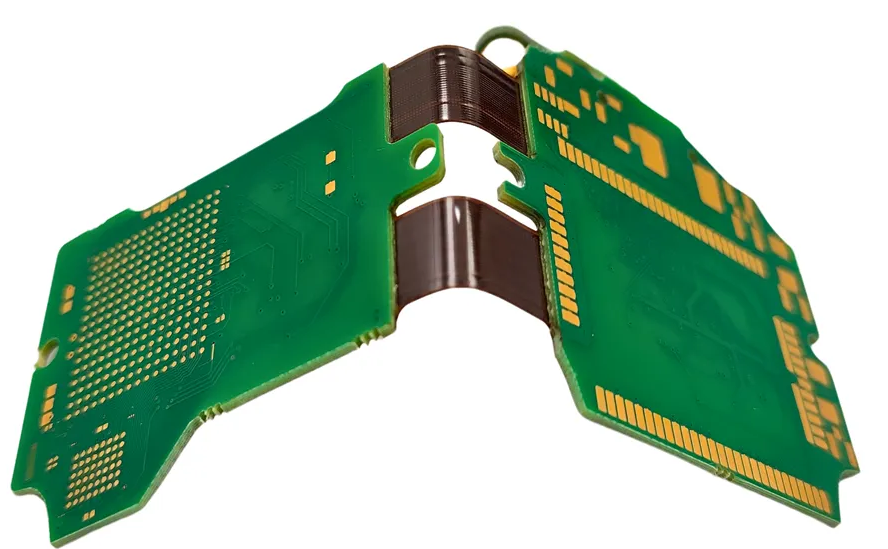

At HRX FPC, customers frequently ask about the cost of rigid flex circuits and why they are priced higher than standard rigid boards and flexible circuits with stiffeners. Typically, a rigid flex PCB will cost about seven times more than a comparable rigid board and two to three times more than a similar flexible circuit with stiffeners. So, what drives the cost of rigid-flex PCBs?

1. Complex Manufacturing Process

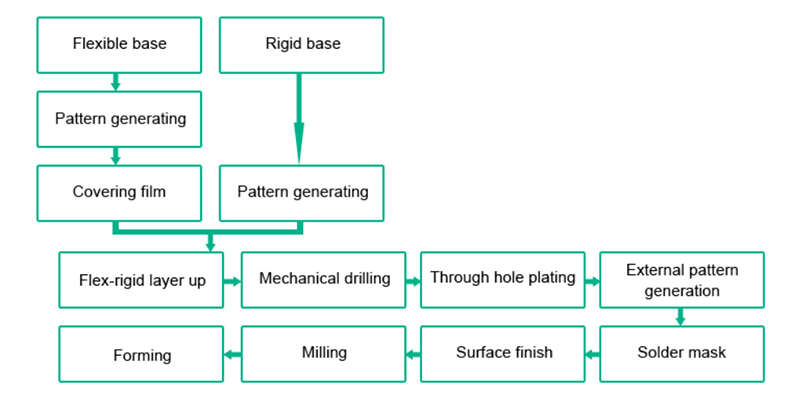

The manufacturing process of rigid-flex PCBs is significantly more complex than that of standard rigid or flexible PCBs. It involves multiple stages that require precise engineering and careful handling:

Layer Stack-Up: Rigid-flex PCBs consist of several layers of flexible circuits sandwiched between rigid boards. This intricate stack-up demands meticulous alignment and bonding processes to ensure reliability and functionality.

Lamination: The flexible and rigid sections need to be laminated together, which involves specialized equipment and materials. Ensuring that the lamination process is void-free and that the layers adhere properly is critical and time-consuming.

Drilling and Plating: Drilling holes through multiple layers, including flexible materials, is challenging. The holes must be plated accurately to maintain electrical connectivity and mechanical integrity across the different sections.

2. Precision and Quality Control

Maintaining high precision and rigorous quality control is crucial in the production of rigid-flex PCBs:

Tolerances: The tolerance levels for rigid-flex PCBs are much tighter than those for standard PCBs. Ensuring that the flexible sections can bend and twist without breaking the electrical connections requires exceptional precision.

Testing: Rigid-flex PCBs undergo extensive testing to verify their mechanical and electrical properties. This includes flex testing, thermal cycling, and other reliability tests that add to the production time and cost.

3. Design Complexity

Designing rigid-flex PCBs is a more intricate task compared to designing traditional PCBs:

CAD Design: The design process involves advanced CAD tools to simulate the mechanical and electrical performance of the board. Designers must consider factors such as bend radii, flex points, and strain relief areas.

Prototyping: Multiple iterations of prototypes are often required to fine-tune the design, which increases both the development time and cost.

4. Lower Production Volumes

Rigid-flex PCBs are typically produced in lower volumes compared to standard rigid or flexible PCBs:

Specialized Applications: They are often used in specialized applications like aerospace, medical devices, and high-end consumer electronics. The lower demand results in higher per-unit costs.

Customization: Each rigid-flex PCB design is highly customized to meet specific requirements, reducing the economies of scale that are achievable with mass production of standard PCBs.

The higher costs associated with rigid-flex PCBs are justified by the significant advantages they offer, including space savings, reduced weight, and enhanced reliability in complex electronic applications. The intricate manufacturing process, specialized materials, stringent quality control, complex design requirements, and lower production volumes all contribute to their premium pricing. Despite the higher costs, the unique capabilities of rigid-flex PCBs make them an invaluable component in cutting-edge technology.

Understanding these cost factors can help engineers and designers make informed decisions when choosing the right type of PCB for their projects, balancing performance needs with budget constraints.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP