Search

What Factors Affect FPC Flexibility?

- Feb 28,2024

-

Share

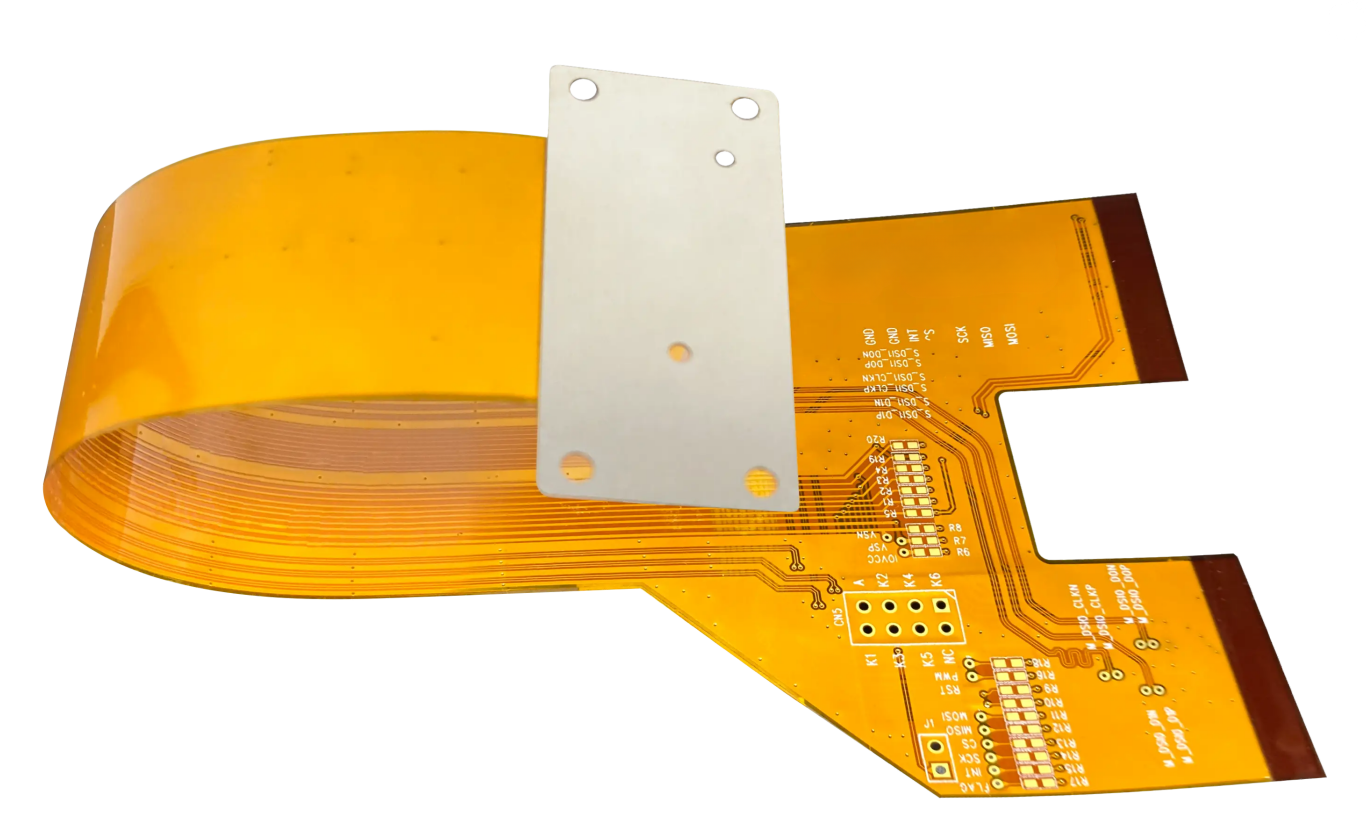

In an era where electronics are becoming increasingly integrated into our everyday lives, flexible circuits have gained significant importance. From wearable devices to foldable screens and medical equipment, FPCs allow engineers to design circuits that can bend, fold, and conform to tight spaces. However, achieving the right balance of flexibility without sacrificing performance remains a critical challenge in FPC design. This blog will explore several methods to improve the flexibility of FPCs, including the use of RA copper, adhesive-free materials, mesh circuit designs, and loose leaf multilayer boards.

Key Factors Influencing FPC Flexibility

The flexibility of an FPC is determined by both the materials used and the structural design. These factors directly impact the circuit's ability to withstand repeated bending and movement. Choosing the right copper type, dielectric materials, and circuit layout can make all the difference in the flexibility of your FPC.

Material Choice: One of the first considerations is the type of copper used. Rolled Annealed (RA) copper, known for its ductility, is preferred over Electro-Deposited (ED) copper in applications requiring dynamic bending. Additionally, using adhesive-free materials like polyimide can enhance flexibility by reducing the overall thickness and eliminating stiff adhesive layers.

Design Structure: The layout of copper traces also plays a major role in flexibility. Solid copper traces are more rigid and prone to cracking when bent repeatedly, while mesh grid designs distribute stress more evenly, increasing the circuit’s lifespan under mechanical strain.

The Role of RA Copper in Flexibility

RA copper is well-known for its excellent mechanical properties, making it the go-to choice for FPCs designed to endure frequent bending and flexing. Its grain structure allows it to deform without breaking, unlike ED copper, which is more brittle and suited for static applications. RA copper provides superior flexibility and is less likely to develop stress fractures over time, making it essential for applications such as wearable technology and medical devices.

Adhesive-Free Materials for Greater Flexibility

Many traditional FPC designs use adhesives between layers, which can hinder flexibility and add unnecessary thickness. Adhesive-free polyimide substrates, on the other hand, offer a thin and flexible alternative that allows for more dynamic movement. These materials also improve heat resistance and overall durability, making them ideal for applications that involve repeated folding or extreme environmental conditions.

Transition from Solid Copper to Mesh Circuit Design

The use of solid copper traces in FPCs may increase rigidity, especially in areas that experience repetitive bending. To improve flexibility, it’s beneficial to transition from solid copper lines to mesh grid designs. A mesh layout reduces the amount of copper used in each trace, lowering the overall stiffness without compromising the electrical integrity of the circuit. Mesh circuits also ensure that stress is evenly distributed across the board, reducing the risk of fractures or delamination in high-flex areas.

Loose Leaf Design for Multilayer Boards

When it comes to multilayer FPCs, flexibility can be even more challenging. Each additional layer increases the stiffness and limits the ability of the board to bend. A loose leaf design helps mitigate this issue by allowing each layer to move independently, reducing the overall stress on the FPC during flexing. This design is especially useful in applications requiring large bending radii, such as foldable displays and flexible medical devices.

Improving the flexibility of FPCs is essential for the next generation of wearable, foldable, and compact electronic devices. By incorporating RA copper, adhesive-free materials, mesh grid designs, and loose leaf multilayer boards, engineers can significantly enhance the flexibility and durability of their circuits. As the demand for more adaptable electronics grows, these innovations will play a crucial role in shaping the future of FPC design. Balancing flexibility with performance is key, and with the right strategies, it's possible to achieve both.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP