Search

What are the stiffener options for FPC

- Apr 12,2023

-

Share

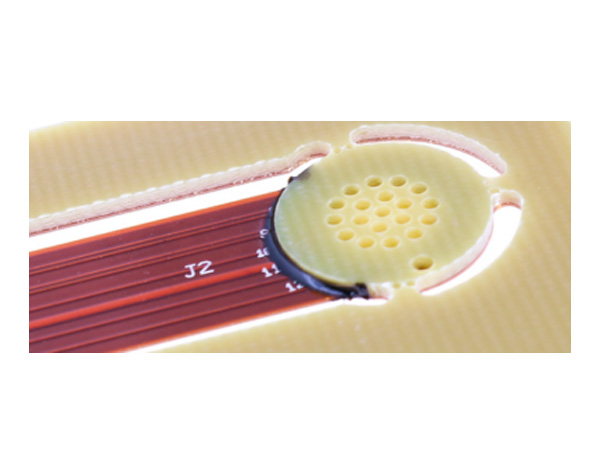

Flexible Printed Circuits (FPCs) have revolutionized the electronics industry with their ability to bend, twist, and conform to irregular shapes, enabling the development of innovative and compact electronic devices. However, to ensure the structural integrity and reliability of FPC assemblies, stiffeners are often employed. In this article, we'll delve into the various stiffener options available for FPCs and their applications.

What is a Stiffener?

Before we explore the options, let's understand the role of a stiffener in FPC assemblies. A stiffener is a rigid material that is attached to the FPC to provide support, reinforcement, and stability, particularly in areas where components are mounted or where mechanical stress is expected.

Types of Stiffener Materials:

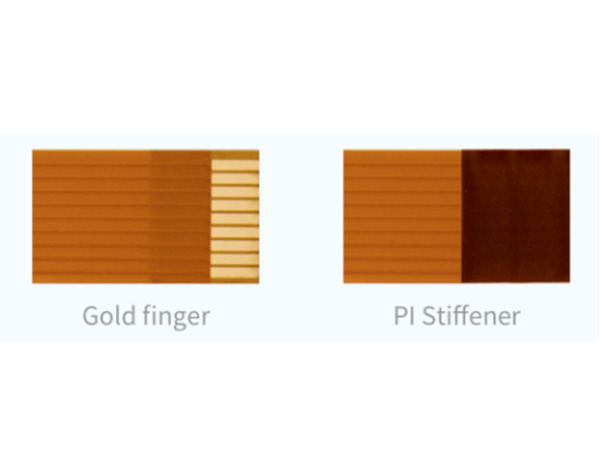

a. Polyimide Stiffeners:

Polyimide is a popular choice for stiffeners due to its excellent thermal stability, chemical resistance, and flexibility. It is well-suited for high-temperature applications and can withstand harsh environments.

b. FR-4 Stiffeners:

FR-4 is a glass-reinforced epoxy laminate known for its rigidity and electrical insulation properties. It offers good mechanical strength and dimensional stability, making it suitable for FPCs in demanding electronic applications.

c. Metal Stiffeners:

Metal stiffeners, such as stainless steel or aluminum, provide superior mechanical strength and durability. They are often used in FPCs where additional support is required to withstand mechanical stress or to improve heat dissipation.

Application Considerations:

When selecting a stiffener for an FPC assembly, several factors should be considered, including:

a. Environmental conditions (temperature, humidity, chemical exposure).

b. Mechanical stress and strain requirements.

c. Electrical insulation and impedance control.

d. Cost and manufacturing feasibility.

In conclusion, choosing the right stiffener option is crucial for ensuring the reliability and performance of FPC assemblies. By understanding the characteristics and applications of different stiffener materials, engineers can make informed decisions to meet the specific requirements of their electronic designs.

Whether it's polyimide, FR-4, or metal stiffener, each option offers unique advantages and considerations. Ultimately, the selection should be based on a comprehensive evaluation of the application's technical requirements, environmental conditions, and cost constraints.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP