Search

Unraveling the Mysteries of Durability and Flexibility in Home Appliance FPCs

- Dec 24,2024

-

Share

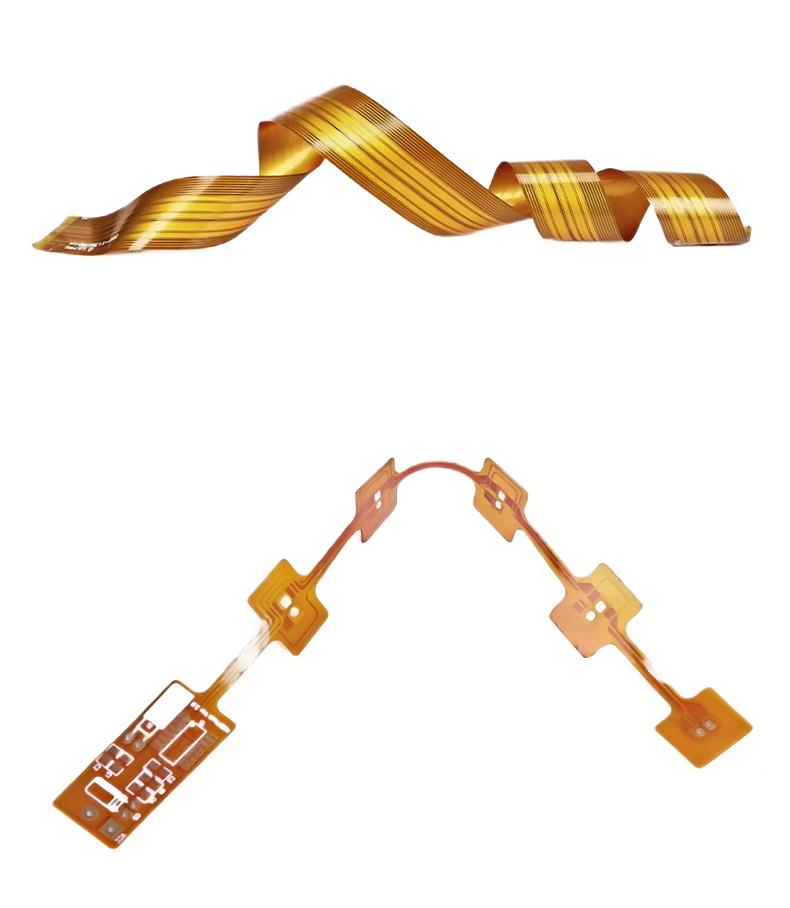

In the electrifying realm of home appliance Flexible Printed Circuit (FPC) design and production, two titans reign supreme: durability and flexibility. These twin pillars not only uphold the integrity of the circuitry but also dictate the very lifespan and performance of our beloved household gadgets. Shenzhen Huaruixin Electronics Co., Ltd., a vanguard in the FPC manufacturing and sales domain, armed with a trove of experience, is here to lift the veil and offer some sagacious counsel.

I. Durability: The Fortress Against the Elements and Stress

The Perils Lurking in the Depths

The Arsenal of Defense and Resilience

II. Flexibility: The Art of Bending Without Breaking

The Trials and Tribulations of Flexibility

The Pathways to Pliable Perfection

Shenzhen Huaruixin Electronics Co., Ltd. is on a noble quest to empower appliance manufacturers to craft FPCs that are the epitome of durability and flexibility. By heeding these insights and implementing the proffered remedies, our home appliances can boast of electrical connections that are as reliable as the rising sun and as enduring as the ages. We extend a warm invitation to our customers to join us in this cerebral symposium, to explore and unearth the optimal FPC solutions for their unique appliance aspirations.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP