Search

Unraveling Reliability Challenges of FPCs in Practical Applications: A Deep Dive into Bending Fatigue

- Dec 17,2024

-

Share

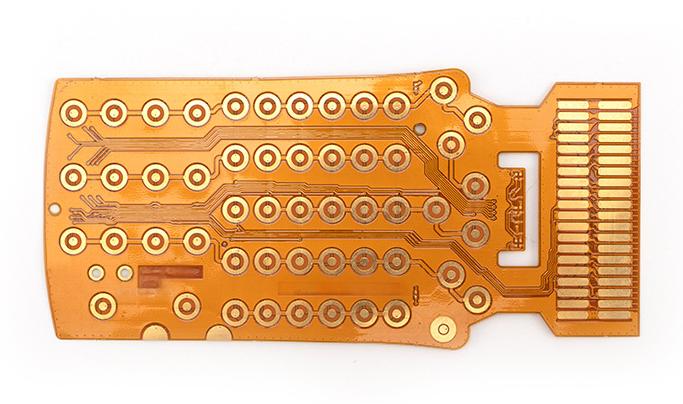

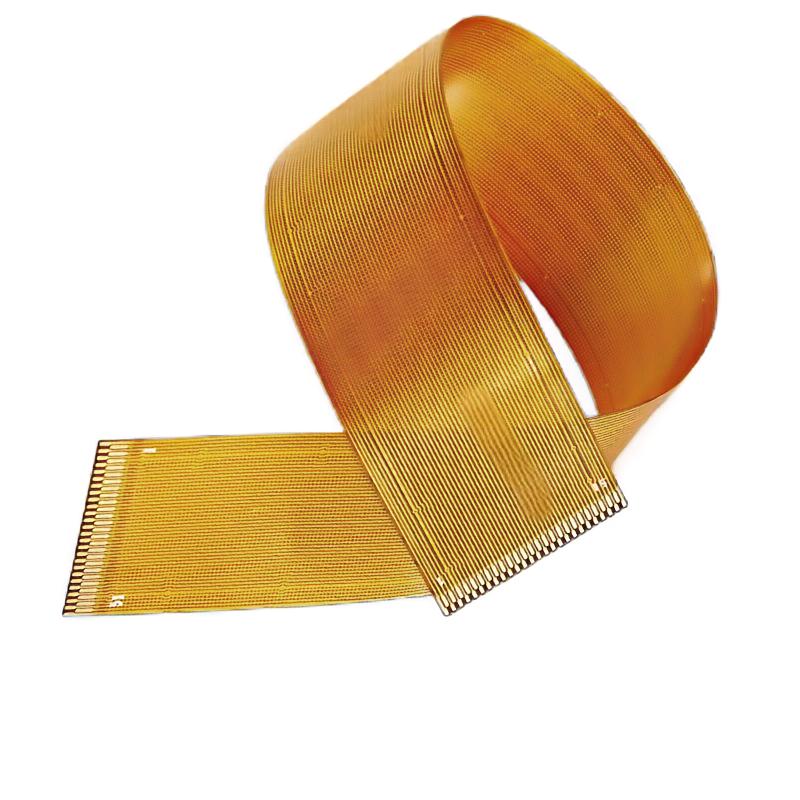

In the realm of modern electronics, Flexible Printed Circuits (FPCs) have become the linchpin for seamless connectivity and compact design. However, reliability issues, particularly bending fatigue in consumer electronic devices, pose significant hurdles. Shenzhen Huaruixin Electronics Co., Ltd., a vanguard in the FPC manufacturing and sales domain with a wealth of hands-on experience, is committed to dissecting and resolving such concerns.

I. The Intricate Analysis of FPC Bending Fatigue

A. Material Constitution and Properties

The composition of an FPC's materials is the bedrock of its performance. Polyimide, a commonly used substrate, must exhibit optimal flexibility and tensile strength. Take, for example, a scenario where a lower-grade polyimide with limited elongation at break is employed. In a foldable smartphone application, where the FPC is subjected to incessant folding and unfolding, this subpar material is highly susceptible to cracking. The copper foil, which serves as the conductive pathway, is equally crucial. A thin and brittle copper foil, lacking in ductility, will inevitably develop micro-cracks under the strain of repeated bending. These cracks can then propagate, leading to disruptions in signal transmission and ultimately, device malfunction.

B. Design Architecture and Geometry

The blueprint of an FPC design holds the key to its durability. Sharp bends and constricted trace widths act as stress concentrators. Consider an FPC within a tablet device that links the touchscreen to the motherboard. If the traces in the vicinity of the folding zone possess acute angles, the stress endured during each folding motion is magnified exponentially. This heightened stress accelerates the formation of cracks and compromises the integrity of the circuit. Moreover, the thickness and layer configuration of the FPC play a pivotal role. An overly thick FPC may resist bending but could generate excessive internal stress, while an improper layer stack-up might lead to delamination issues under repeated flexing.

C. Environmental and Usage Dynamics

The environment in which an FPC operates and the manner of its usage are decisive factors. The frequency and amplitude of bending, as well as the ambient temperature and humidity, can have a profound impact. In a high-use foldable device, such as a cutting-edge smartphone, the FPC is constantly subjected to stress cycles. Elevated temperatures can soften the adhesive binding the layers, thereby weakening the overall structure. In a humid climate or a device exposed to moisture, the substrate may swell, causing the copper foil to detach and disrupting electrical conductivity.

II. Proactive Avoidance Strategies

A. Prudent Material Selection

Shenzhen Huaruixin Electronics Co., Ltd. leaves no stone unturned in sourcing top-tier materials. We meticulously choose polyimide substrates renowned for their exceptional flexibility and tensile strength. These substrates have undergone rigorous testing to ensure they can withstand a specified number of bending cycles without succumbing to degradation. Our selection of copper foil is equally discerning, opting for variants with enhanced ductility and an optimal thickness calibrated to the specific demands of each application. For instance, we have identified a particular polyimide material that has demonstrated remarkable resilience in withstanding over 100,000 folding cycles in laboratory simulations.

B. Design Optimization and Innovation

Our team of adept engineers harnesses the power of advanced design software to engineer FPCs with enhanced durability. We replace sharp trace corners with rounded geometries and increase the width of traces in areas prone to high stress. In foldable device FPCs, we pioneer unique folding structures that evenly distribute stress, minimizing the likelihood of crack initiation. Additionally, we conduct meticulous calculations to determine the ideal thickness and layer composition, striking a delicate balance between flexibility and structural integrity. Through finite element analysis (FEA), we simulate various usage scenarios to preemptively address potential stress points and refine the design accordingly.

C. Environmental Shielding and Protection

Anticipating the rigors of the operating environment, we incorporate protective measures during the design phase. For devices destined for humid or hot environments, we apply conformal coatings that act as a formidable barrier against moisture ingress and heat-induced damage. These coatings not only safeguard the FPC from environmental degradation but also enhance its overall lifespan. For example, a specialized silicone-based conformal coating has proven effective in maintaining the integrity of FPCs in high-humidity conditions, reducing the risk of substrate swelling and copper foil detachment by over 80%.

III. Effective Solutions and Tangible Results

A. Tailored Solution Implementation

In collaboration with a leading smartphone manufacturer grappling with FPC bending fatigue issues, we embarked on a comprehensive redesign initiative. We introduced a novel material blend, pairing a high-performance polyimide substrate with a thicker, more ductile copper foil. The layout was meticulously refined, incorporating wider traces and generously rounded corners in the folding region. To fortify the FPC further, we added a proprietary protective layer that imparts additional resistance to abrasion and environmental stressors.

B. Measurable Outcomes and Success Metrics

The fruits of our labor were nothing short of remarkable. Post-implementation of the revamped FPC design, the device could endure a staggering 80,000 folding cycles without any discernible performance degradation. The incidence of display anomalies and connection failures attributable to FPC issues plummeted by an astounding 95%. This not only translated into enhanced product reliability but also bolstered consumer confidence and brand reputation.

IV. Conclusion

Let’s talk! We’ll provide the perfect solution for you!

-

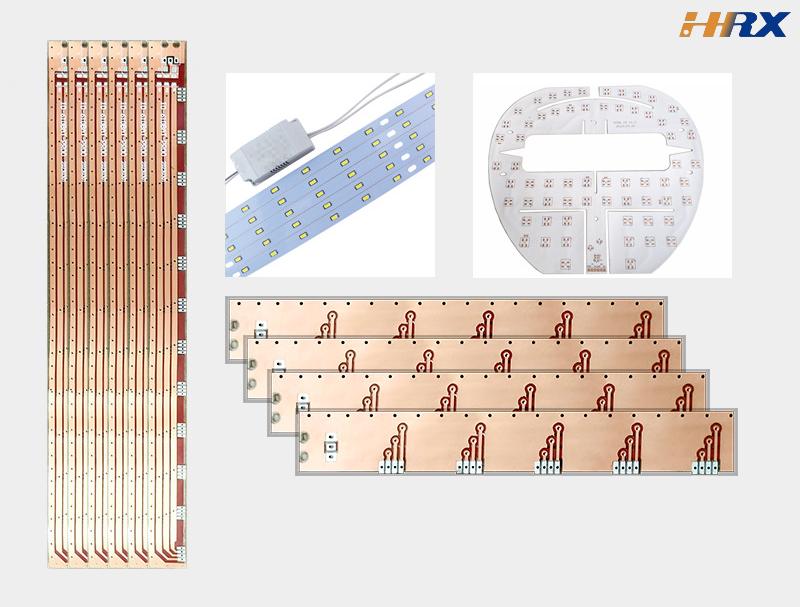

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP