Search

Understanding X-out Boards in PCB Manufacturing and Their Impact on SMT Efficiency

- Aug 21,2024

-

Share

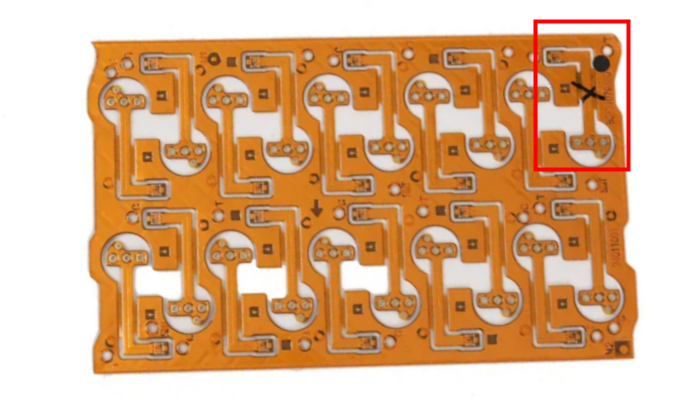

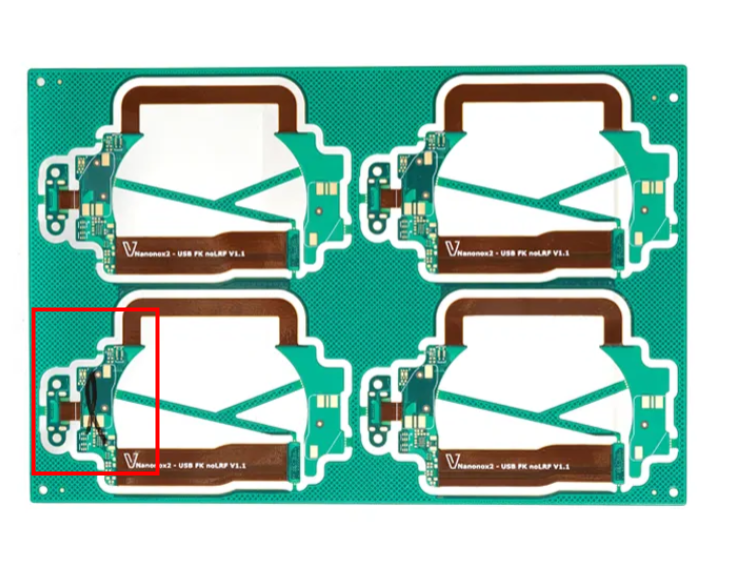

In the FPC or PCB manufacturing, the term “X-out” (also referred to as “Cross-board” or “X-board”) denotes defective boards that are marked with an X on the top of the PCB panel. These marks indicate that the board is unusable, usually due to production defects. X-out boards are a common challenge faced by PCB manufacturers, and managing them is crucial for ensuring both product quality and operational efficiency.

Why X-out Boards Matter

During the PCB production process, X-out boards are inevitable—especially in larger panels. The more PCBs present in a single panel, the higher the likelihood that some will be defective. However, allowing these defective boards into the production line can significantly affect the efficiency of downstream processes, particularly during Surface Mount Technology (SMT) assembly.

The Impact on SMT Efficiency

In the SMT process, defective X-out boards slow down production and create inefficiencies. SMT factories typically aim to maintain a smooth, uninterrupted flow of boards through their assembly lines. However, when X-out boards are present, they must either be bypassed, causing delays, or lead to manual intervention in the production line. For this reason, most SMT factories do not accept panels containing X-out boards, as they disrupt the efficiency of automated processes.

Acceptable Quality Level (AQL) for X-out Boards

Given that X-out boards are often unavoidable, the PCB industry has established standards for managing them. The Acceptable Quality Level (AQL) dictates the permissible percentage of X-out boards in a panel. Typically:

· In a panel with 4 PCBs, only 1 X-out board is allowed (i.e., 25% of the total).

· In a panel with 8 PCBs, 2 X-out boards are permitted.

The total amount of X-out boards must also be less than 10% of the total shipment. These guidelines ensure that defects are kept within reasonable limits, balancing quality control and cost management.

Handling X-out Boards in Shipment

When shipping PCBs with X-out boards, proper packaging and clear labeling are essential. X-out boards must be positioned consistently within each panel to allow for easy identification. If the number of X-out boards is less than the total package quantity, the remaining panels should be packed in a separate box (referred to as the "mantissa box"), and the total quantity of both functional PCBs and X-out boards should be clearly marked.

Buyers’ Role in Managing X-out Boards

Buyers of PCBs have the option to either allow or reject X-out boards in their shipments. If buyers permit X-out boards to exist within the panels, SMT factories can adjust their assembly programs to skip over defective boards by identifying the bad marks, but this adjustment results in a loss of efficiency in the SMT process.

On the other hand, if buyers do not allow X-out boards, the PCB manufacturer is required to produce additional panels to replace those containing defective boards. This process results in a higher production cost but ensures maximum SMT efficiency by eliminating disruptions caused by X-out boards.

Striking a Balance: Cost vs. Efficiency

The presence of X-out boards presents a trade-off between cost and efficiency. Buyers must consider whether they are willing to accept X-out boards and manage them in their SMT processes, or whether the added cost of eliminating X-out boards is worth the gain in efficiency. For PCB manufacturers, striking the right balance between quality control and production output is essential for meeting customer expectations while maintaining cost-effectiveness.

X-out boards are an inherent challenge in PCB production, and their management requires careful coordination between manufacturers and buyers. By understanding the AQL standards, packaging requirements, and impact on SMT processes, businesses can make informed decisions that optimize both cost and efficiency in their operations.

In the end, achieving the right balance ensures that the PCB manufacturing process runs smoothly while minimizing defects and maintaining the high-quality standards required for today’s complex electronic devices.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP