Search

Understanding the Importance of Impedance Control in PCB Design

- Oct 04,2024

-

Share

As technology advances, PCBs are becoming more complex and compact, with high-speed transmission and signal integrity being critical in many applications. In such environments, impedance control plays a key role in ensuring smooth and reliable signal transmission. This post explores what impedance control is, why it is vital in PCB design, and how to achieve it through thoughtful design practices.

What is Impedance Control in PCBs?

Impedance is a combination of capacitance and inductance, representing the opposition to current flow in a circuit. In high-frequency applications, impedance must be carefully managed to prevent signal distortion as it travels between the source and receiver. Impedance control ensures that signal transmission remains clear and stable, helping to maintain the integrity of the signal from start to finish.

The goal of impedance control in PCBs is to manage the electrical resistance throughout the board, preventing uncontrolled variations that could lead to signal degradation, especially in high-speed or high-frequency circuits.

Why is Impedance Control Crucial in PCB Designs?

In modern devices like smartphones, computers, and other electronics, the demand for high-frequency signal transmission has increased significantly. Impedance control is essential in these applications for several reasons:

· Maintaining Signal Integrity: Impedance control ensures clear signal transmission by matching the impedance of PCB traces, preventing data loss or corruption.

· Consistent Electrical Flow: By regulating impedance, the flow of electricity is more predictable, allowing circuits to operate reliably at high frequencies.

· Optimized for Complex Designs: As PCB designs become more intricate, controlled impedance helps reduce the negative effects that complex layouts can have on signal performance.

· Preventing Signal Reflection: When the impedance of a trace matches the source and load, signal reflection is minimized, leading to better signal quality.

Overall, controlled impedance allows PCBs to handle the demands of high-frequency signals more effectively, ensuring that devices perform as intended.

Key Factors for Achieving Good Impedance Control in PCBs

To achieve controlled impedance, designers must consider several important factors during the PCB design process:

1. Spacing Between Traces and Planes: The distance between signal traces and ground or power planes is critical in controlling impedance. For high-frequency signals, the vertical spacing between the signal layer and its reference plane must be optimized to match the desired impedance.

2. Trace Geometry: The width, thickness, and overall geometry of the PCB traces significantly affect impedance. Careful calculation of trace dimensions is necessary to ensure that the impedance is within acceptable limits for high-frequency signals.

3. Dielectric Material Selection: The dielectric constant (Dk) of the material used between the PCB layers also impacts impedance. The dielectric material should be chosen based on its compatibility with the signal traces to maintain consistent impedance values.

By managing these factors, PCB designers can ensure that the board performs well under high-frequency conditions, supporting the transmission of high-speed signals without loss or distortion.

Conclusion

As PCBs continue to shrink in size and increase in complexity, impedance control is becoming more critical than ever, especially for high-frequency applications. A well-designed PCB with controlled impedance helps ensure signal integrity, enabling devices to perform reliably even in the most demanding environments.

If you're looking for a trusted partner to help you design PCBs with controlled impedance, working with a reliable manufacturer is key. A professional PCB manufacturer can help you navigate the complexities of impedance control and deliver boards that meet the performance standards of modern electronics.

By following these guidelines and working with experienced manufacturers, you can create PCBs that support advanced technologies and maintain signal integrity in high-frequency applications.

Let’s talk! We’ll provide the perfect solution for you!

-

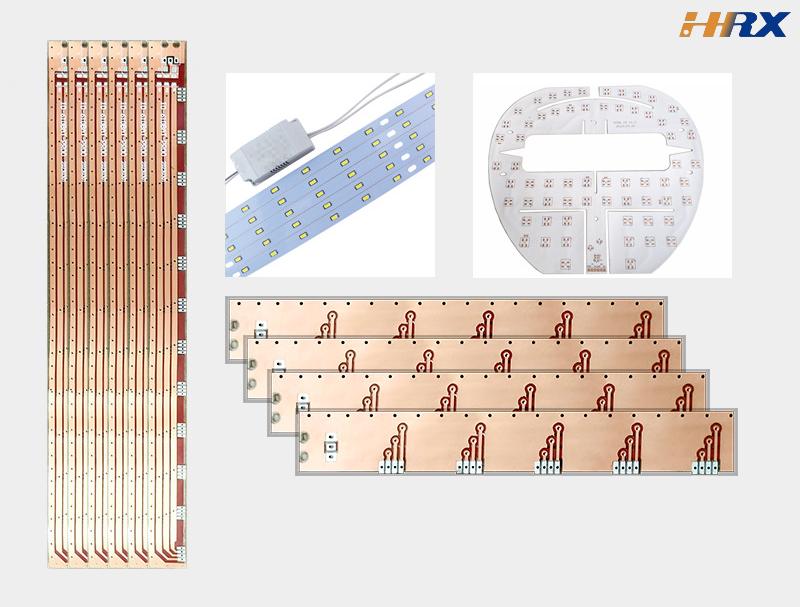

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

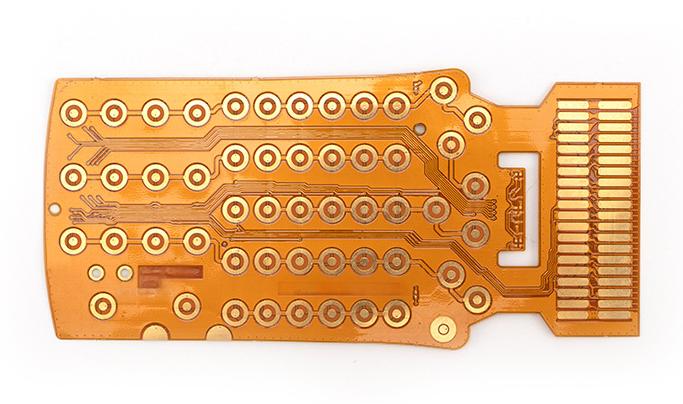

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP