Search

Understanding the Differences and Applications of PI, FR4, and Stainless Steel Stiffeners in FPC

- Dec 05,2023

-

Share

Flex PCB have revolutionized modern electronics by enabling compact, lightweight, and flexible designs. However, flexibility can sometimes pose challenges, especially when rigidity or additional support is needed. This is where FPC stiffeners come into play. Stiffeners are added to FPCs to provide mechanical support, ensure reliability, and improve the overall performance of the circuit. In this blog, we’ll explore the three most common types of FPC stiffeners: PI (Polyimide), FR4, and Stainless Steel, discussing their unique properties, typical applications, and how to choose the right one for your design needs.

What Are FPC Stiffeners?

FPC stiffeners are reinforcing materials attached to specific areas of a flexible circuit to enhance its rigidity. They are essential for various reasons, such as improving connector insertion durability, providing a stable platform for surface-mount devices (SMD), or facilitating reliable soldering processes. Without these stiffeners, the flexible nature of FPCs might lead to failures in mechanical stress situations, such as during repeated insertions or in areas requiring precise alignment.

Types of FPC Stiffeners

PI (Polyimide) Stiffener

PI, or Polyimide, is a popular choice for FPC stiffeners due to its excellent thermal stability, flexibility, and dielectric properties. It is typically used behind gold fingers—those conductive strips on the edge of FPCs that connect with external connectors. The main purpose of the PI stiffener in this context is to achieve a total thickness that ensures secure and reliable insertion into connectors. PI stiffeners are available in various thicknesses, typically ranging from 0.05mm to 0.2mm, allowing designers to meet specific design requirements. The benefits of PI stiffeners include ease of processing, compatibility with various adhesives, and their contribution to the overall robustness of the FPC.

FR4 Stiffener

FR4 is a glass-reinforced epoxy laminate that offers excellent mechanical strength and durability. It’s widely used in traditional rigid PCBs and serves as an effective stiffener in FPC designs, particularly when additional support is needed for SMD components or through-hole soldering. FR4 stiffeners provide a stable and rigid platform, ensuring that components remain securely in place and that solder joints maintain their integrity during thermal cycling and mechanical stress. Typical thicknesses for FR4 stiffeners range from 0.2mm to 2.0mm, depending on the specific application. FR4 is especially beneficial in situations where a robust, non-flexible support is crucial for maintaining the overall functionality of the circuit.

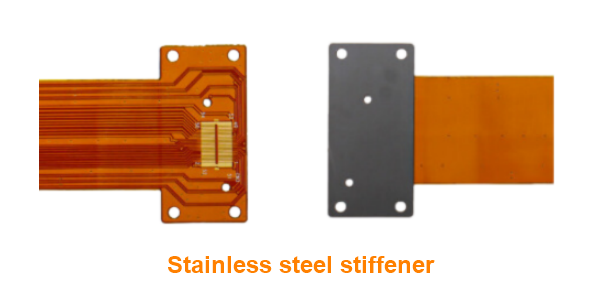

Stainless Steel Stiffener

For applications that demand superior rigidity and grounding capabilities, Stainless Steel stiffeners are the ideal choice. Stainless Steel offers the highest mechanical strength among the common stiffener materials, making it suitable for situations where the FPC must endure harsh conditions or repeated mechanical stress. Additionally, Stainless Steel stiffeners can be used to provide a grounding plane, which is particularly valuable in high-frequency or EMI-sensitive applications. The thickness of Stainless Steel stiffeners typically ranges from 0.1mm to 0.3mm, depending on the level of rigidity required. While more challenging to process due to its hardness, the benefits of using Stainless Steel in demanding environments outweigh the complexities.

Applications and Selection Criteria

Selecting the right stiffener for your FPC design depends on several factors, including the mechanical demands of the application, the required rigidity, thermal performance, and whether grounding is needed.

· For connector insertion areas (e.g., gold fingers), PI stiffeners are often the best choice due to their flexibility and ease of achieving the required thickness.

· For areas with SMD components or where through-hole soldering is required, FR4 stiffeners offer the necessary mechanical support to ensure reliable assembly and operation.

· For high-rigidity or grounding applications, Stainless Steel stiffeners provide unparalleled strength and can help manage electromagnetic interference (EMI).

Understanding these factors will help in making the most appropriate choice, ensuring that the FPC performs reliably throughout its lifecycle.

Conclusion

Incorporating the right stiffener in an FPC design is critical to achieving the desired performance and longevity of the circuit. PI, FR4, and Stainless Steel stiffeners each offer distinct advantages tailored to specific applications. By carefully considering the needs of your project, you can select the stiffener that will provide the necessary support, durability, and functionality.

Have you worked with FPC stiffeners before? Share your experiences or challenges in the comments below! If you’re looking for expert advice on choosing the right stiffener for your next project, feel free to reach out. We’re here to help you design the most reliable and efficient FPC solutions.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP