Search

The Pivotal Role of FPC in the Medical Device Landscape

- Apr 15,2025

-

Share

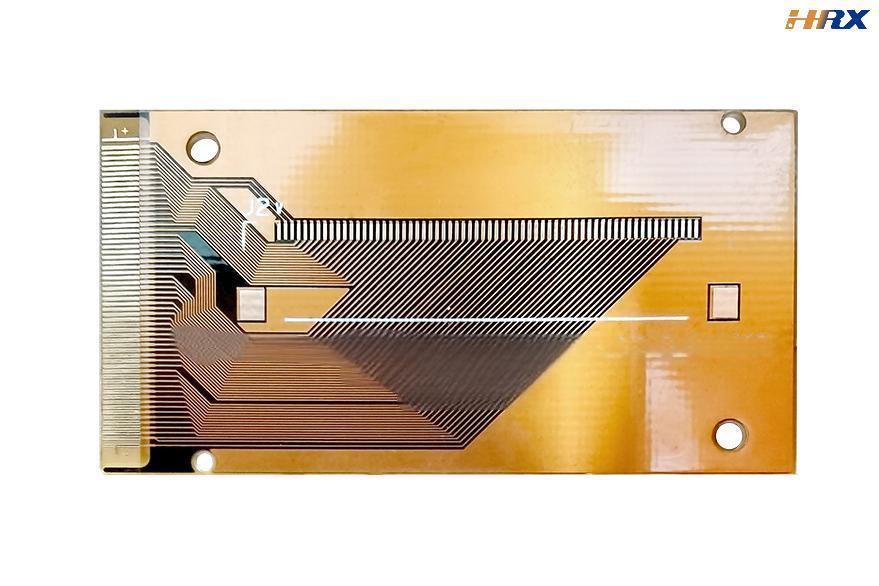

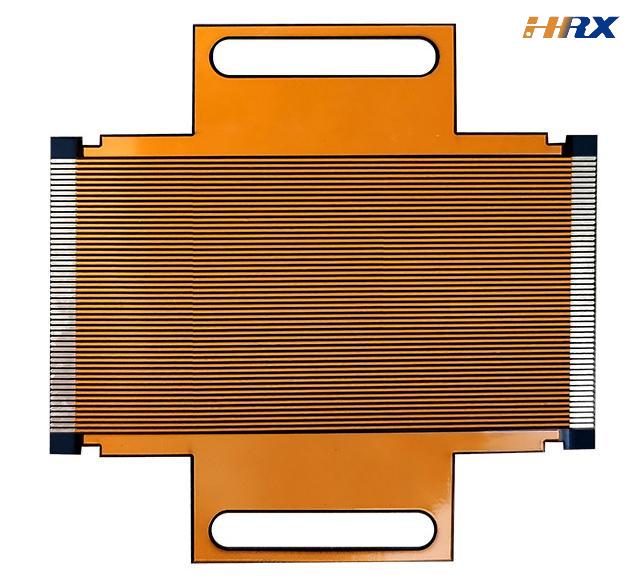

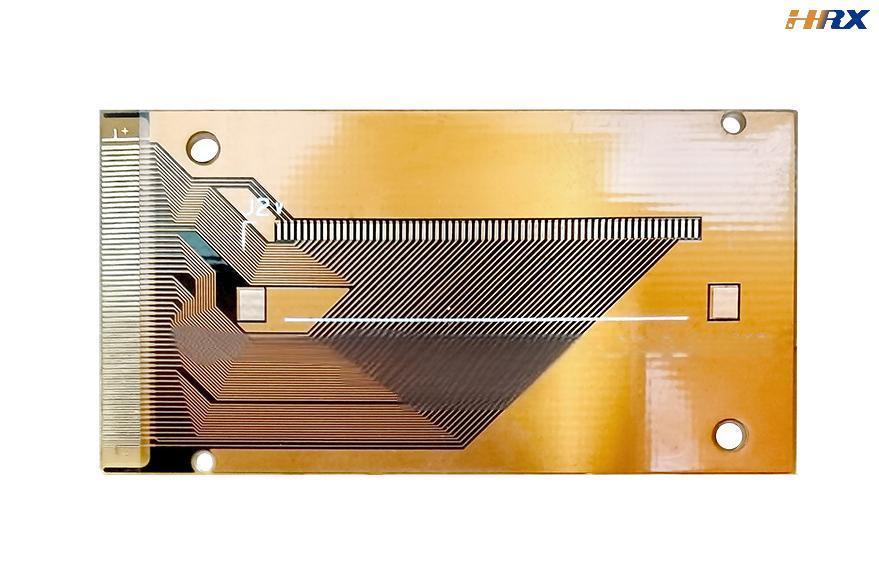

In the dynamic realm of medical devices, the twin imperatives of miniaturization and hyper - precision are driving a technological revolution. As healthcare demands escalate, medical devices are shrinking in physical dimensions while simultaneously striving for unparalleled accuracy. This paradigm shift has catapulted Flexible Printed Circuits (FPC) to the forefront of innovation, with their omnipresence in critical components such as high - sensitivity sensors, high - resolution displays, and intricate circuit boards.

At Shenzhen Huaruixin Electronics Co., Ltd., our prowess in FPC technology is a cut above the rest. Our team of seasoned engineers, boasting extensive tenures in the design and fabrication of FPC, PCB, and Rigid - Flex Printed Boards, has an intimate understanding of the idiosyncratic demands of the medical device sector. FPCs bring a plethora of advantages to medical equipment. Their inherent flexibility allows for seamless integration into the compact and convoluted designs of contemporary medical devices. This not only facilitates the achievement of a more streamlined form factor but also bolsters the device's durability, as FPCs can better endure vibrations and mechanical stress encountered during normal operation.

Our Stringent Production Process

Raw Material Procurement

We source our raw materials from a cadre of trusted suppliers, adhering to a zero - tolerance approach towards quality. For FPC manufacturing, base materials like high - grade polyimide films and electrolytic copper foils are meticulously selected. Our procurement team wields advanced inspection tools to ensure that incoming materials meet our exacting standards. Only materials with uniform thickness, superior electrical conductivity, and high - temperature resilience are green - lighted for production.

Design and Layout

Our design mavens collaborate closely with clients, translating their visions into highly detailed FPC blueprints. Leveraging state - of - the - art Electronic Design Automation (EDA) software, we optimize circuit layouts to minimize electromagnetic interference (EMI) and maximize spatial utilization. Each design undergoes multiple rounds of rigorous peer review to ensure its technical viability and compliance with the exacting standards of the medical device industry.

FPC Manufacturing

Etching Process

During the etching phase, we deploy advanced subtractive etching techniques to precisely etch away unwanted copper from the copper - clad laminate. Achieving the ultra - fine traces requisite for medical device applications demands unrivaled precision. Our automated etching systems are calibrated at regular intervals to guarantee consistent etching depth and linewidth tolerance within micron - level accuracy.

Plating

To augment the FPC's electrical conductivity and corrosion resistance, we execute both electroplating and electroless plating processes. The plating thickness is precisely controlled, tailored to the specific requirements of each project, using advanced thickness - monitoring equipment.

Assembly

Our skilled technicians, trained in the latest Surface Mount Technology (SMT) and through - hole assembly techniques, meticulously assemble FPC components. This includes the precise attachment of high - reliability connectors and other electronic elements, following a strict Standard Operating Procedure (SOP) to ensure optimal alignment and secure connections.

Final Testing and Packaging

Prior to dispatch, FPCs are subjected to an exhaustive battery of tests. Electrical testing, including in - circuit testing (ICT) and functional testing, is carried out to verify circuit integrity. Insulation resistance testing is performed to safeguard against electrical leakage, and mechanical flexibility testing simulates real - world usage conditions. Only products that pass these stringent tests are carefully packaged, using anti - static and moisture - resistant materials, for delivery.

Our Robust Quality Control Regime

In - line Quality Checks

Throughout the production continuum, we have multiple in - line quality control checkpoints. Trained quality inspectors, armed with high - magnification microscopes, automated optical inspection (AOI) systems, and electrical test fixtures, vigilantly search for defects such as short circuits, open circuits, and sub - standard etching. Any non - compliant products are immediately removed from the production line for rework or, if necessary, scrapped.

Final Inspection

Post - testing, a comprehensive visual and dimensional inspection is carried out. High - magnification digital microscopes are used to detect even the most minuscule surface defects on the FPC, while precision measuring instruments, such as coordinate measuring machines (CMMs), are employed to ensure that the FPC's dimensions adhere to the design specifications with micron - level precision.

Quality Management System

We operate under a rigorous Quality Management System (QMS) that is fully compliant with international benchmarks such as ISO 9001. This QMS serves as the backbone of our operations, ensuring that every aspect of production, from raw material sourcing to after - sales service, is executed with unwavering quality focus.

Our extensive industry experience has equipped us with the acumen to anticipate and surmount potential challenges in the manufacturing process. Over the years, we have refined our production techniques and quality control protocols to consistently deliver top - tier FPC products. In the medical device industry, where patient safety is non - negotiable, the reliability of FPCs is of paramount importance. A malfunctioning FPC in a medical device can have grave consequences for patient well - being.

We have forged successful partnerships with numerous medical device manufacturers. A prime example is our collaboration with a leading global company in the development of a next - generation portable blood glucose monitor. The client required a high - performance, compact FPC solution for sensor - to - display connectivity. Our team engaged with them from the ground - up, commencing with the initial design ideation. By harnessing our advanced manufacturing capabilities, we produced FPCs with sub - micron - level ultra - fine traces, which were instrumental in facilitating high - precision signal transmission for the glucose sensor. The outcome was a marked improvement in the accuracy of blood glucose readings. Additionally, the FPC's compact design contributed to the overall miniaturization of the device, enhancing its portability and user - friendliness. This project was a resounding success, with the product garnering widespread acclaim in the global market.

Beyond portable medical diagnostic devices, FPCs have also carved a niche in the burgeoning field of smart medical wearable devices. These wearables, designed for long - term, unobtrusive use, demand lightweight and flexible components. FPCs, with their ability to be seamlessly integrated into fabric - based or form - fitting structures, offer reliable electrical connectivity while maintaining the device's comfort and flexibility.

If you are seeking innovative FPC, PCB, or Rigid - Flex Printed Board solutions for your medical device projects, we invite you to get in touch. Visit our website at www.hrxfpc.com to explore our comprehensive product portfolio and service offerings. For inquiries, please email us at sales@hrxfpc.com. We also encourage industry professionals, new and old, to engage in knowledge exchange and collaborative learning. We firmly believe that through continuous dialogue and learning, we can propel FPC technology forward and better serve the evolving needs of the medical device industry and beyond.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP