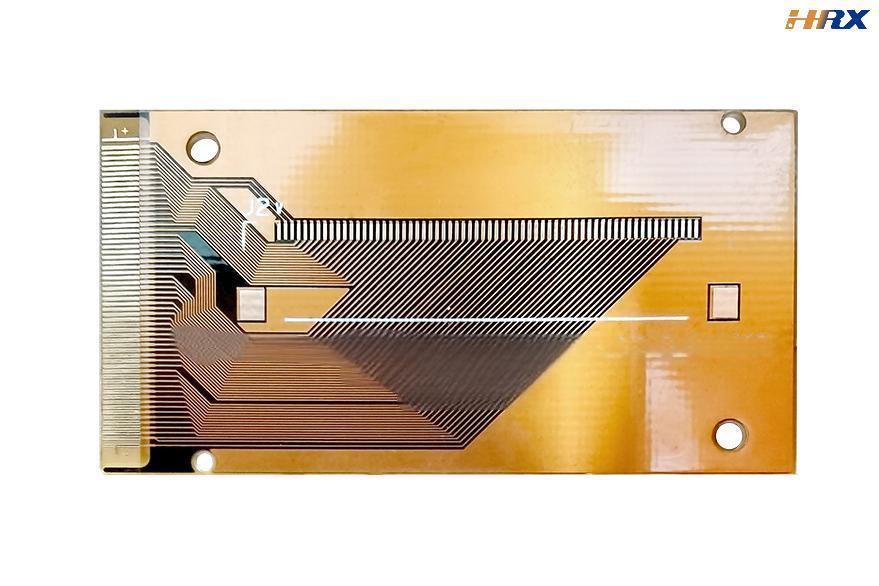

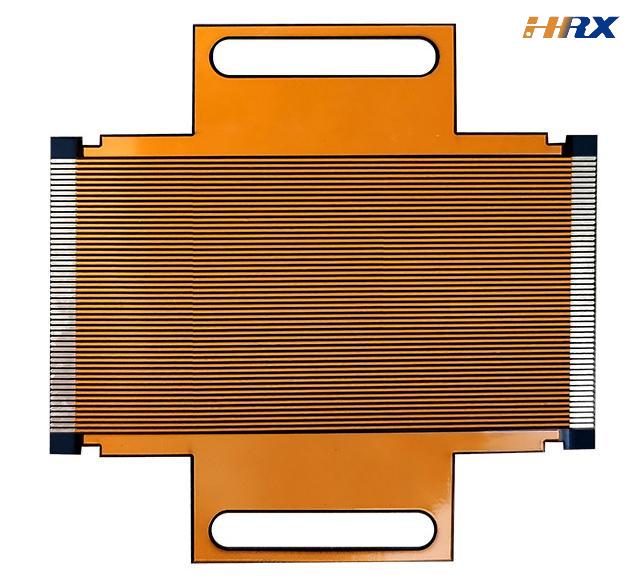

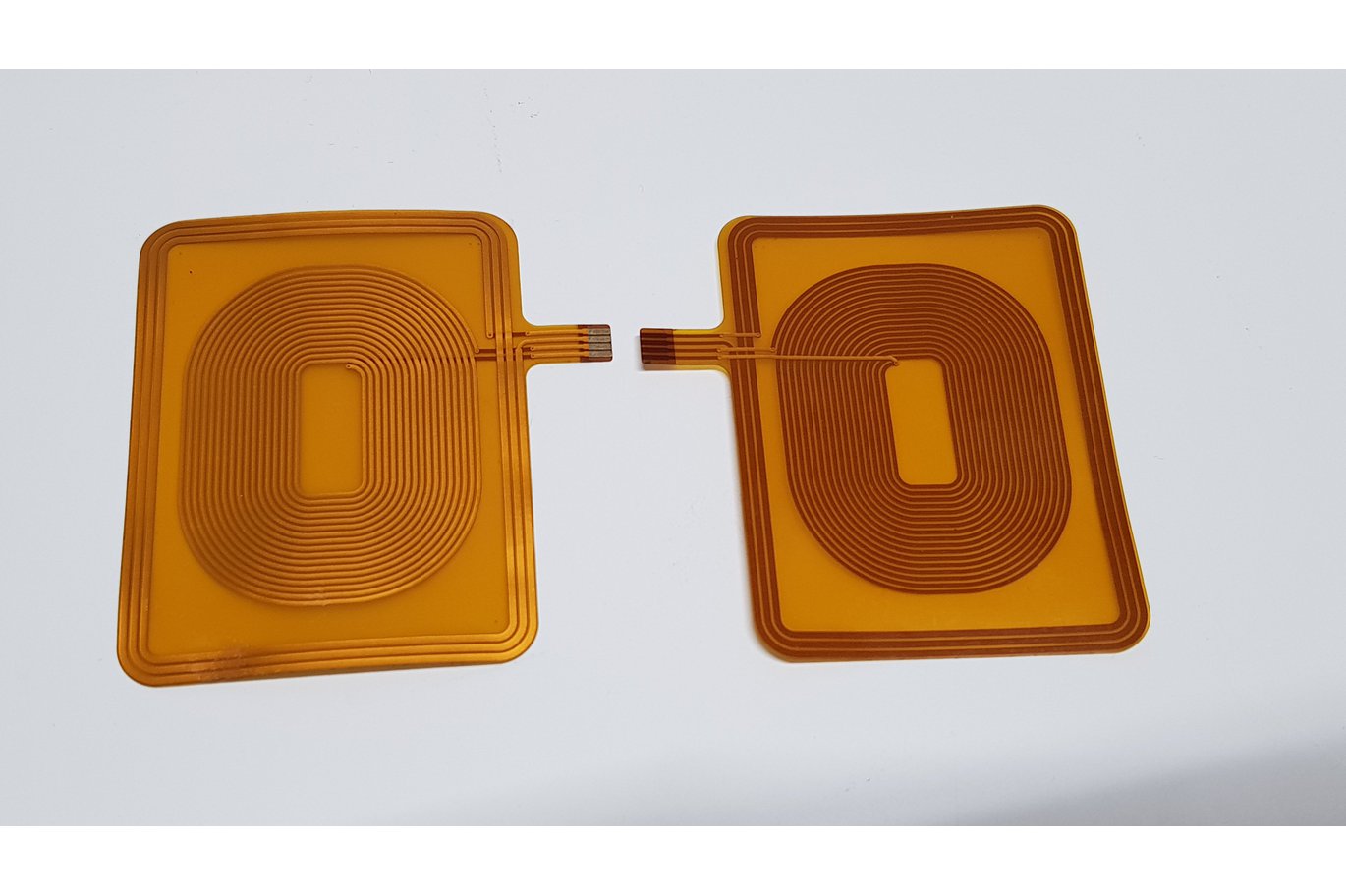

Flexible circuits are essential components in various electronic devices due to their adaptability, light weight, and ability to connect components in tight spaces. Given the critical nature of FPCs, ensuring their reliability and performance through rigorous testing is vital. Below are key methods and standards used in testing FPC boards.

1. Appearance of the Base Film

The visual inspection of the base film (substrate) is a fundamental aspect of FPC testing. Defects in the substrate where the conductor is not present are permitted within the scope outlined in standardized tables. However, any wrinkles, creases, embedded foreign objects, or other deformations that could affect performance or usability are strictly prohibited.

2. Appearance of the Cover Layer

The appearance of the cover film and coating is also carefully inspected. Any defects in the cover film, such as uneven surfaces, creases, or delamination, are allowed only within specified limits. Defects that could impact the functionality, such as bulging or layer separation, are not permitted, ensuring the integrity of the circuit is maintained throughout its lifespan.

3. Deviation of Pads and Cover Layer

Alignment between the connection pads and the cover layer is another critical factor. For circuits with dimensions smaller than 100 mm, the permissible deviation between the pad and cover layer is limited to ±0.3 mm. For circuits larger than 100 mm, the allowed deviation is a maximum of ±0.3% of the overall dimensions. Maintaining this tight tolerance ensures that the alignment does not affect the electrical connectivity or assembly process.

4. Flow of Adhesive and Cover Coating

The degree of adhesive or cover coating flow should not exceed 0.2 mm. However, when inspecting the connection pads, the combined deviations in the cover layer and punching process must satisfy the minimum ring width (g ≥ 0.05 mm). This precision is crucial in preventing short circuits or other connectivity issues in high-density designs.

5. Discoloration of the Conductor Under the Cover Layer

After subjecting the FPC to a humidity resistance test at 40°C and 90% humidity for 96 hours, the conductor under the cover layer should not exhibit discoloration. Even after such testing, the FPC must continue to meet the standards for voltage resistance, bending resistance, flexibility, and soldering performance. This ensures the circuit remains functional in harsh environmental conditions, a common requirement in various industrial applications.

6. Coating Defects

Parts of the conductor that lack proper coating are evaluated based on solderability requirements. In such cases, no tin should adhere to uncoated sections of the conductor. This standard helps maintain the circuit's overall reliability and ensures proper function during soldering and assembly processes.

7. Poor Electroplating Adhesion

Any separation or poor adhesion of the electroplating layer is unacceptable. The width (W1) and length (L) of poorly adhered plating, as well as the width (W) of the conductor after processing, are strictly monitored to ensure these issues do not compromise the reliability of contact areas. Poor adhesion can lead to weak connections, which may cause circuit failure during use.

Conclusion

FPC boards are used in a wide variety of industries where performance and reliability are critical. Meeting these stringent testing standards is essential to ensuring that FPCs function properly in their intended applications. By focusing on factors such as appearance, alignment, adhesive flow, discoloration, and electroplating quality, manufacturers can confidently deliver products that meet high-performance requirements across a range of environments.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.