Search

Tenting Vias in FPC: Design and Production Considerations

- Nov 11,2024

-

Share

What are Tenting Vias?

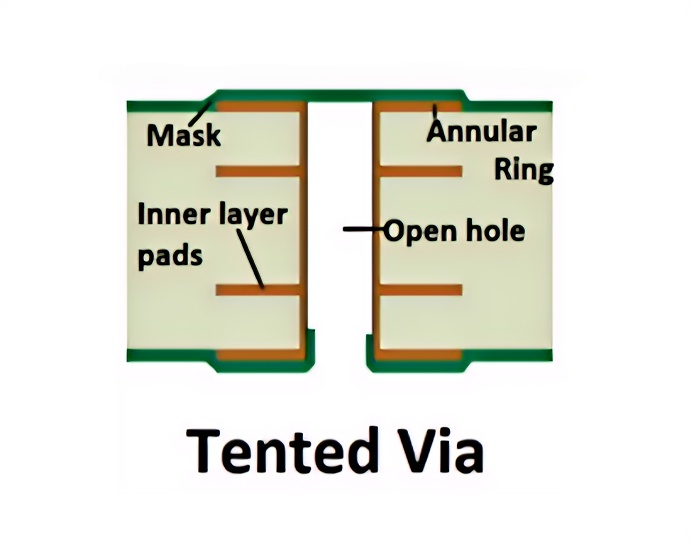

Tenting vias are vias that are covered with a layer of solder mask or other insulating material. This process is used to prevent solder from flowing into the vias during the soldering process and to provide electrical isolation.

1. Via size and spacing: The size and spacing of the vias should be carefully considered to ensure that there is enough room for the tenting material and that the vias are not too close together, which could lead to bridging or other issues.

2. Material selection: The material used for the tenting should be compatible with the FPC material and the soldering process. Common materials include solder mask, polyimide film, and epoxy resin.

3. Design for manufacturability: The design should be optimized for manufacturability, taking into account factors such as drilling accuracy, registration, and processing time.

1.Process control: The tenting process should be carefully controlled to ensure consistent coverage and quality. This includes monitoring the thickness and uniformity of the tenting material, as well as ensuring that there are no voids or defects.

2.Quality inspection: Quality inspection should be performed at various stages of the production process to detect any issues with the tenting vias. This can include visual inspection, electrical testing, and cross-sectional analysis.

3. Environmental considerations: The production environment should be clean and free from contaminants that could affect the quality of the tenting vias. This includes controlling dust, humidity, and temperature.

Case 1: In a recent project for a high-end consumer electronics device, our team designed and produced an FPC with tenting vias that provided excellent electrical isolation and reliability. The vias were carefully sized and spaced to ensure optimal performance, and the tenting material was selected for its compatibility with the soldering process and environmental requirements.

Case 2: For an automotive application, we designed an FPC with tenting vias that could withstand the harsh environmental conditions of the vehicle. The tenting material was chosen for its durability and resistance to temperature, vibration, and moisture. The production process was carefully controlled to ensure consistent quality and reliability.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP