Search

RA copper vs ED copper, which is better?

- Mar 13,2024

-

Share

Electronics engineers often grapple with the question of whether to use Electro-Deposited (ED) copper or Rolled Annealed (RA) copper for FPC production. Both materials are highly regarded in the industry, but each has distinct characteristics that make them suitable for different applications. This article delves into the main differences between ED and RA copper, helping you determine which type is best for your specific needs.

Rolled Annealed (RA) Copper

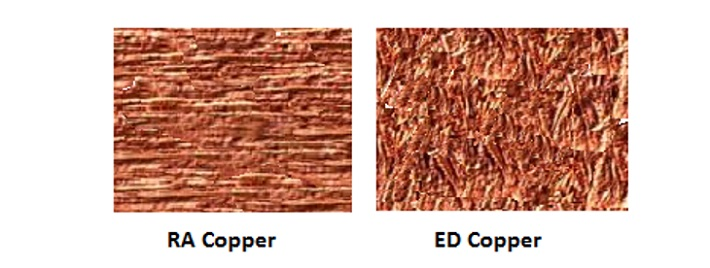

Production Process: RA copper is manufactured by rolling a copper block into thin foils and then annealing it at high temperatures. This process results in a smooth, flexible copper foil with a lamellar crystal structure.

Characteristics:

Flexibility: RA copper is highly flexible, making it suitable for applications that require bending and flexing.

Smooth Surface: It has a smoother surface compared to ED copper, which is beneficial for high-frequency signals.

Thermal Properties: RA copper offers excellent thermal cycling resistance, making it ideal for thermally demanding applications.

Applications: RA copper is extensively used in flex circuits and rigid-flex PCB fabrication, where flexibility and high-frequency performance are critical.

Understanding ED Copper

Production Process: ED copper is produced through an electro-deposition process where copper ions are deposited onto a substrate in an electrolyte bath. This method allows for precise control over the thickness and surface finish of the copper foil.

Characteristics:

High Conductivity: ED copper boasts excellent electrical conductivity, making it ideal for applications where signal integrity is crucial.

Surface Finish: It has a slightly rougher surface compared to RA copper, which can enhance adhesion with the laminate.

Cost-Effective: The production process is relatively straightforward, making ED copper a cost-effective option for many PCB applications.

Applications: ED copper is commonly used in consumer electronics such as cell phones and digital cameras, where high conductivity and low weight are essential.

Comparing ED Copper and RA Copper

Flexibility:

RA Copper: More flexible due to its grain structure and annealing process, making it ideal for dynamic, flexible circuitry.

ED Copper: Less flexible but offers higher conductivity and is more cost-effective.

Surface Roughness:

RA Copper: Smoother surface (0.35 microns RMS), beneficial for high-frequency applications.

ED Copper: Slightly rougher surface, which can improve adhesion but may increase insertion loss.

Cost:

RA Copper: Generally more expensive due to the complex manufacturing process.

ED Copper: More cost-effective, making it a preferred choice for high-volume production.

Applications:

RA Copper: Best for flexible PCBs, high-frequency signals, and applications requiring significant bending.

ED Copper: Ideal for consumer electronics, high-speed dynamic applications, and scenarios where cost is a significant factor.

Which is Better for Your PCB?

The choice between ED copper and RA copper depends on the specific requirements of your PCB application. Here are some guidelines:

For Flexibility: Choose RA copper if your PCB needs to bend or flex frequently.

For High Conductivity: Opt for ED copper if electrical conductivity is your top priority.

For Cost-Effectiveness: ED copper is the more budget-friendly option.

For High-Frequency Applications: RA copper’s smoother surface makes it better suited for high-frequency signals.

Mechanical Properties

When considering mechanical properties, ED copper excels in applications with high thermal and mechanical stress, while RA copper offers superior thermal cycling resistance. The choice here will depend on the specific mechanical and thermal demands of your PCB.

Both ED copper and RA copper have their unique advantages, making them suitable for different types of PCB applications. By understanding the differences in their production processes, characteristics, and mechanical properties, you can make an informed decision that aligns with your project's specific needs.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP