Search

Plugged Vias in FPC: Design and Production Insights

- Nov 13,2024

-

Share

In the domain of Flexible Printed Circuits (FPC), plugged vias are a significant aspect that demands careful attention during both design and production phases. Shenzhen Huaruixin Electronics Co., Ltd., a specialized FPC production and sales company, is here to share valuable knowledge regarding this crucial element.

Understanding Plugged Vias

Plugged vias in FPCs are vias that are filled or covered to prevent issues such as solder wicking, short circuits, or interference with other components. They play a vital role in maintaining the integrity and functionality of the FPC.

Design Considerations

1. Via Size and Shape:The size and shape of the vias to be plugged need to be carefully determined. Smaller vias might be easier to plug accurately, but they could also pose challenges during the plugging process if the equipment used has limited precision. For example, in some high - density FPC designs, vias with a diameter of 0.2mm or less require specialized plugging techniques. The shape of the via, whether circular, square, or rectangular, can also impact the plugging process and the subsequent performance of the FPC.

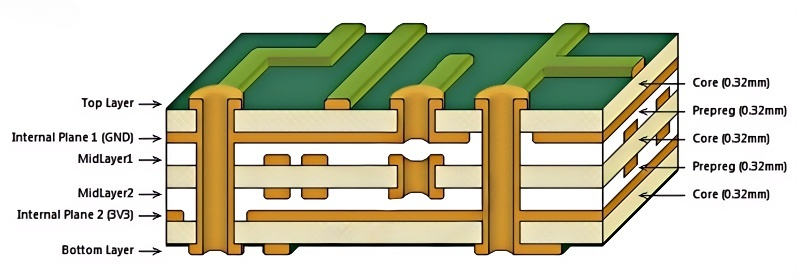

2.Location and Distribution:The location of plugged vias within the FPC layout is crucial. They should be strategically placed to avoid interference with signal paths and other components. In designs where there are multiple layers and complex routing, careful consideration of via distribution is necessary. For instance, in an FPC for a mobile device motherboard, plugged vias are positioned away from the antenna area to prevent any negative impact on signal transmission.

3. Compatibility with Materials: The choice of plugging material must be compatible with the FPC substrate and other materials used in the circuit. Different materials have different thermal expansion coefficients and chemical properties. For example, if the FPC uses a polyimide substrate, the plugging material should have similar thermal stability to avoid delamination during temperature variations.

Production Considerations

1.Plugging Process Selection: There are various methods for plugging vias, such as using conductive or non - conductive pastes, epoxy resins, or mechanical inserts. Each method has its own advantages and disadvantages. For high - volume production, an automated dispensing system for paste - based plugging might be more efficient. However, for applications requiring high mechanical strength, mechanical inserts could be a better choice. The production process must be carefully controlled to ensure uniform plugging quality.

2.Quality Control: During production, strict quality control measures are essential. Visual inspection can detect any visible defects such as incomplete plugging or over - spillage of the plugging material. Additionally, electrical testing can be performed to ensure that there are no short circuits or open circuits caused by the plugged vias. For example, in - line electrical testing can quickly identify any faulty vias before the FPC proceeds to the next production stage.

3.Process Optimization: To improve production efficiency and reduce costs, continuous process optimization is necessary. This can involve adjusting the parameters of the plugging process, such as the dispensing speed and pressure for paste - based plugging. Also, analyzing production data to identify bottlenecks and areas for improvement can enhance the overall quality of the plugged vias.

Successful Design Cases

1.Medical Device FPC: In a project for a medical monitoring device, our team at Shenzhen Huaruixin Electronics designed an FPC with plugged vias. The vias were carefully sized and located to avoid interference with the sensitive sensor signals. We used a non - conductive epoxy resin for plugging, which provided excellent electrical isolation. The FPC was able to function reliably in the high - precision medical environment, with no issues of signal interference or short circuits due to the well - designed and produced plugged vias.

2.Industrial Control FPC: For an industrial control system FPC, we had to deal with harsh environmental conditions including high temperatures and vibrations. The plugged vias were designed with a larger diameter to accommodate mechanical inserts. These inserts were made of a high - strength, temperature - resistant material. The production process was optimized to ensure that each via was properly plugged, and the FPC has been operating stably in the industrial environment for years, demonstrating the effectiveness of our design and production approach for plugged vias.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP