Search

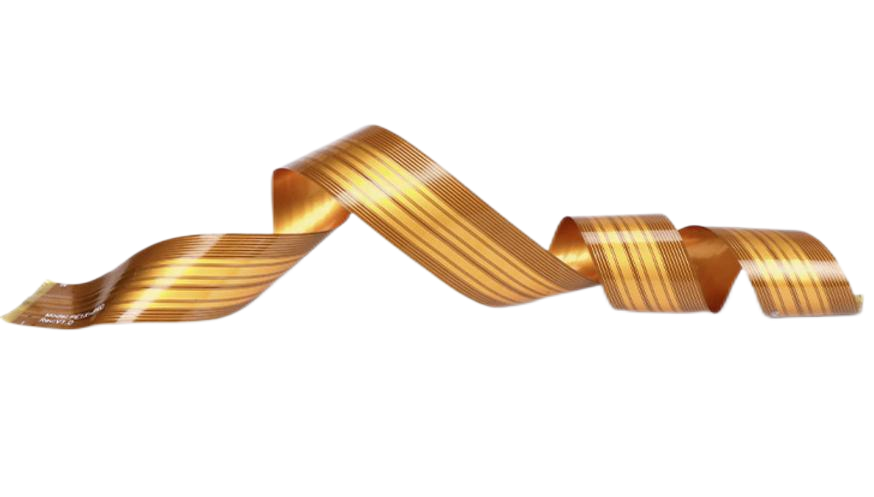

Overcoming Challenges in FPC Soft Cable and Flexible Circuit Board Bend Life Design and Production

- Nov 25,2024

-

Share

In the realm of FPC soft cable and flexible circuit board design and production, especially when it comes to bend life, numerous obstacles need to be surmounted. This blog will explore how to break through these barriers, common mistakes to avoid, the role of testing experiments in analysis, selection strategies, and present some successful design cases. Shenzhen Huaruixin Electronics Co., Ltd., a professional FPC manufacturer with a wealth of experience, welcomes new and old customers to engage in discussions and collaborative learning.

I. Breaking Through Bend Life - related Barriers

A. Material Innovation

B. Circuit Design Optimization

C. Manufacturing Process Refinement

II. Common Mistakes to Avoid Based on Testing Experiments

A. Ignoring Material Compatibility

When selecting materials for different layers of the FPC, it's essential to ensure their compatibility. Incompatible materials can lead to delamination or chemical reactions during bending. For example, if an adhesive reacts with the substrate or the conductive layer, it can cause the FPC to fail prematurely. Material compatibility tests, such as thermal cycling and humidity tests combined with bending, can identify such issues before mass production.

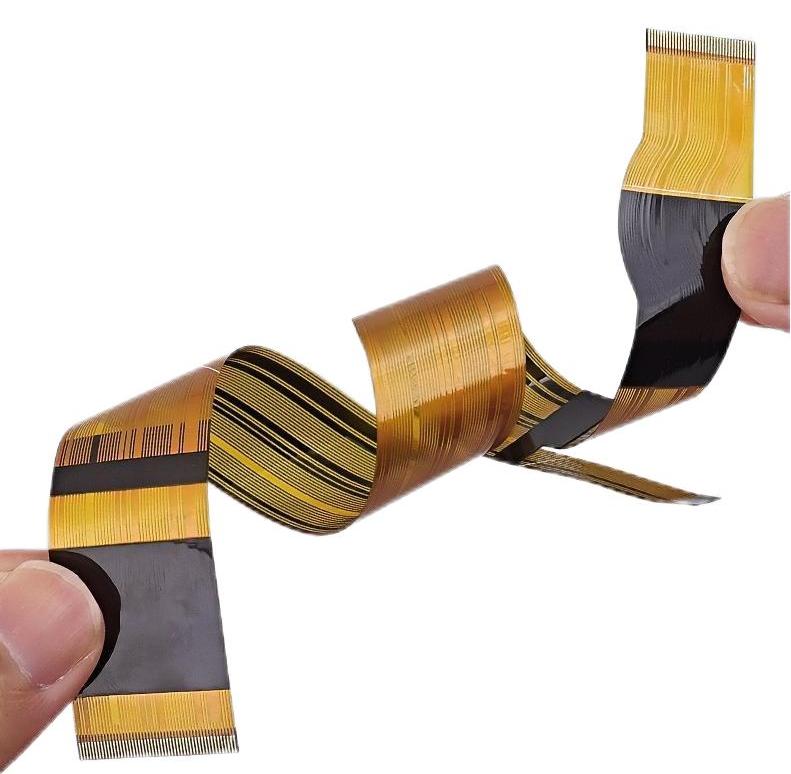

B. Overlooking Bend Radius Limitations

Designing an FPC without considering the minimum bend radius it will experience in its application is a common mistake. If the FPC is bent beyond its limit, cracks and breaks will occur. Bend radius tests should be carried out during the design phase to determine the safe operating range. This information can then be used to guide the circuit design and material selection. For example, if a particular application requires a small bend radius, a more flexible substrate and thinner copper layers may be necessary.

C. Neglecting Environmental Factors in Testing

The performance of an FPC can be significantly affected by environmental conditions such as temperature, humidity, and exposure to chemicals. Testing only under standard laboratory conditions and ignoring the real - world environment can lead to inaccurate predictions of bend life. Environmental testing experiments, including temperature - humidity - bias (THB) tests combined with bending, can provide a more comprehensive understanding of the FPC's performance. For example, in a high - humidity environment, moisture can penetrate the FPC and cause corrosion or swelling, reducing its bend life.

D. Inadequate Sampling in Testing

To obtain reliable results from testing experiments, an adequate sample size is crucial. Testing only a few FPCs and basing design decisions on those results can be misleading. Statistical analysis should be used to determine the appropriate sample size based on the desired level of confidence and accuracy. For example, if a new material or design change is being evaluated, a larger sample size may be required to detect any significant differences in bend life.

III. Selection Based on Testing Results

A. Supplier Selection

When choosing an FPC manufacturer, look for a company that has a strong track record in bend life performance. Shenzhen Huaruixin Electronics Co., Ltd. is an excellent example. They conduct extensive testing on their products and can provide detailed test reports. A reliable supplier should have a well - established quality control system that includes bend life testing at various stages of production. Additionally, they should be able to offer customization options based on specific bend life requirements.

B. Material Selection

Based on the results of material testing experiments, select materials that have demonstrated excellent bend life characteristics. Consider not only the initial performance but also the long - term stability. For example, a substrate material that shows minimal degradation in bend life after aging tests is preferable. The same goes for conductive layers and adhesives. Look for materials that have been tested under a variety of conditions and have consistently met or exceeded the required bend life standards.

C. Design Option Selection

Evaluate different design options using the results of circuit design and manufacturing process testing. Choose the design that offers the best combination of bend life, electrical performance, and manufacturability. For example, if a particular trace routing and via design has shown superior bend life in testing while still meeting the electrical requirements, it should be selected. Consider the cost - effectiveness of different design options as well. A more complex design that offers only a marginal improvement in bend life may not be worth the additional cost.

IV. Successful Design Cases

A. FPC for a Foldable Smartphone

Shenzhen Huaruixin Electronics Co., Ltd. designed an FPC for a foldable smartphone. The substrate was a modified PI material with added nanoparticles, which significantly increased its flexibility and resistance to cracking. The conductive layer consisted of a thin, ductile copper foil with a nickel - gold plating for enhanced durability. The circuit design optimized the trace routing and via design to minimize stress during folding. Through extensive testing, including thousands of folding cycles under different environmental conditions, the FPC demonstrated excellent bend life. It was able to withstand the repeated folding and unfolding of the smartphone without any loss in electrical performance, ensuring a reliable connection between the different components of the device.

B. FPC for a Flexible Medical Device

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP