Search

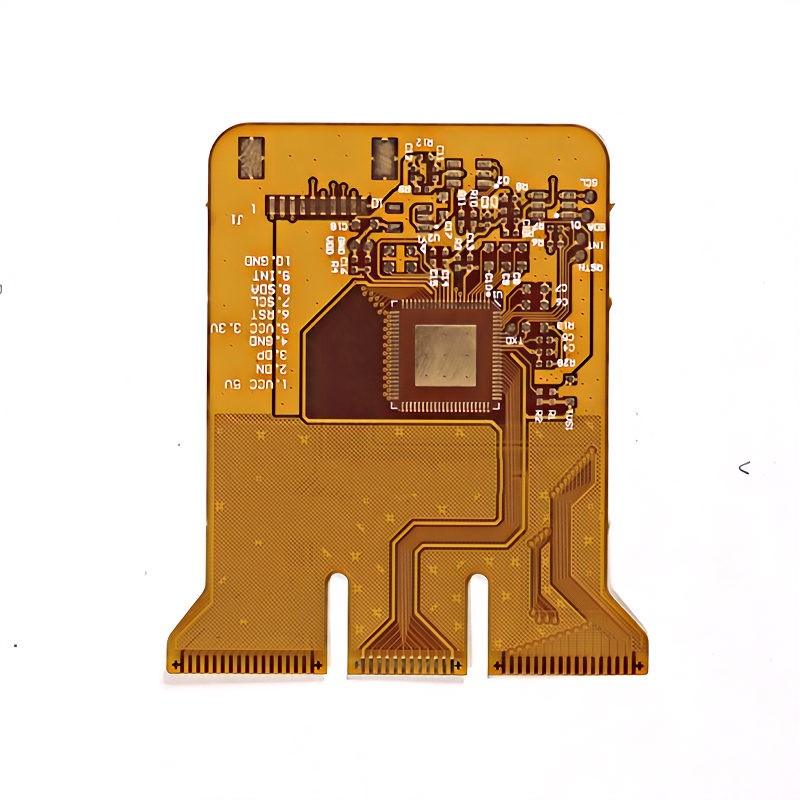

Optimizing Routing in High-Multi-Layer HDI Rigid-Flex PCB Technology

- Nov 05,2024

-

Share

In the realm of high-multi-layer HDI rigid-flex printed circuit boards (PCBs), optimizing routing is crucial for ensuring reliable performance and efficient functionality. Here are some key strategies to achieve optimal routing in this advanced technology.

1. Thorough Planning and Design

Before starting the routing process, it's essential to conduct a comprehensive analysis of the circuit requirements. Understand the signal types, frequencies, and power distributions that will be present on the board. This knowledge will help in making informed decisions about layer stack-up, trace widths, and spacing.

Create a detailed design plan that takes into account the flexibility and rigidity sections of the PCB. Determine the optimal placement of components to minimize signal paths and reduce interference. Use advanced PCB design software that allows for 3D visualization and simulation to preview the routing and identify potential issues early on.

2. Signal Integrity Considerations

For high-speed signals, signal integrity is of utmost importance. Minimize crosstalk by keeping high-speed traces as far apart as possible from other signals. Use ground planes and shielding to further reduce crosstalk and electromagnetic interference.

Control impedance by carefully designing trace widths and spacing to match the characteristic impedance of the signal. Impedance mismatches can lead to signal reflections and degradation. Use simulation tools to verify impedance values and make adjustments as needed.

3. Flexibility and Bend Areas

In the flexible sections of the HDI rigid-flex PCB, special attention must be given to routing. Use wider traces and larger bend radii to reduce stress on the copper during flexing. Avoid sharp bends and kinks that can cause cracks and signal failures.

Design the routing to accommodate the expected flexing cycles and ensure that the traces can withstand the mechanical stresses without breaking. Consider using reinforcement materials or cover layers in the flex areas to enhance durability.

4. Power and Ground Distribution

A stable power supply and proper ground distribution are essential for optimal performance. Design dedicated power and ground planes to minimize impedance and provide a clean power source to the components. Use multiple vias to connect the power and ground planes throughout the board to ensure uniform distribution.

Avoid long power traces and minimize the use of power loops to reduce electromagnetic interference and voltage drops. Place decoupling capacitors close to the power pins of high-speed components to filter out noise and improve signal stability.

5. Manufacturing Constraints

Be aware of the manufacturing limitations and constraints when optimizing routing. Consult with the PCB manufacturer to ensure that the designed routing can be fabricated reliably and cost-effectively. Consider factors such as minimum trace widths, via sizes, and layer-to-layer spacing.

Use design for manufacturability (DFM) guidelines to avoid common manufacturing issues such as drill hits, trace shorts, and soldering problems. Conduct a design rule check (DRC) before finalizing the routing to ensure compliance with the manufacturing process.

In conclusion, optimizing routing in high-multi-layer HDI rigid-flex PCBs requires a combination of careful planning, signal integrity considerations, flexibility management, power and ground distribution, and awareness of manufacturing constraints. By following these strategies, designers can achieve reliable and high-performance PCBs that meet the demanding requirements of modern electronic applications.

In search of top-notch PCB solutions? Shenzhen Huaruixin Electronics Co., Ltd is here for you! We specialize in high-multi-layer HDI rigid-flex PCB technology. Our team's expertise is dedicated to serving your unique needs. Whether it's complex designs or tight deadlines, we've got you covered. You have the need, we have the know-how. Let's collaborate and create great things together!

Let’s talk! We’ll provide the perfect solution for you!

-

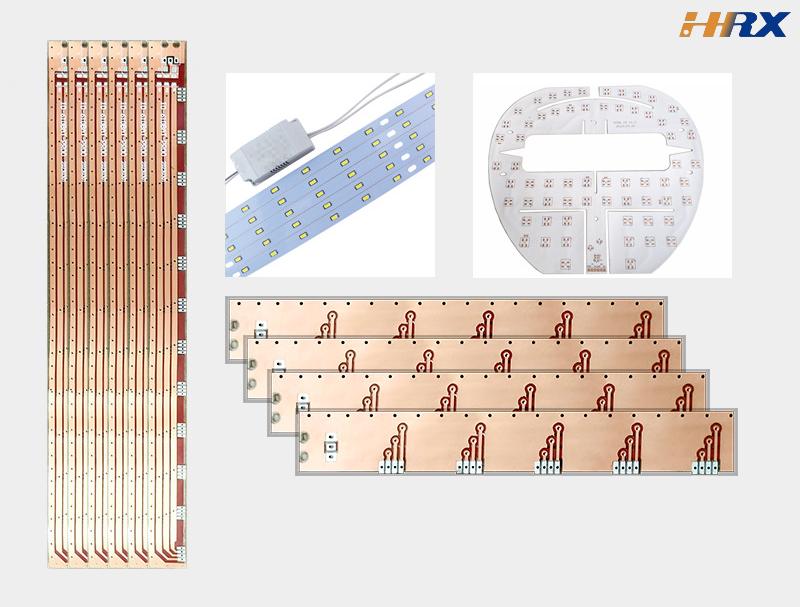

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

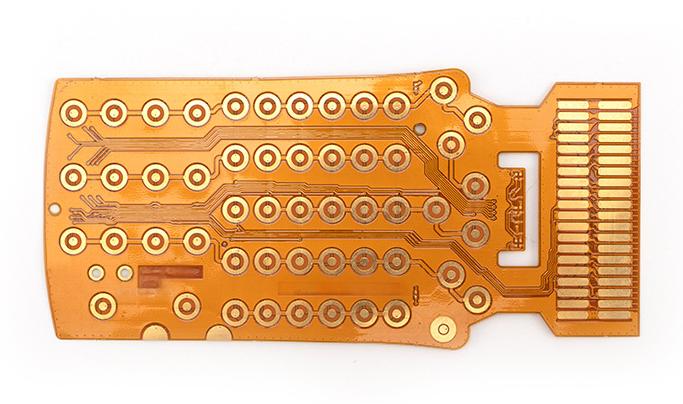

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP