Search

Optimizing Rigid - Flex Printed Board Design for Enhanced Production Efficiency

- Mar 20,2025

-

Share

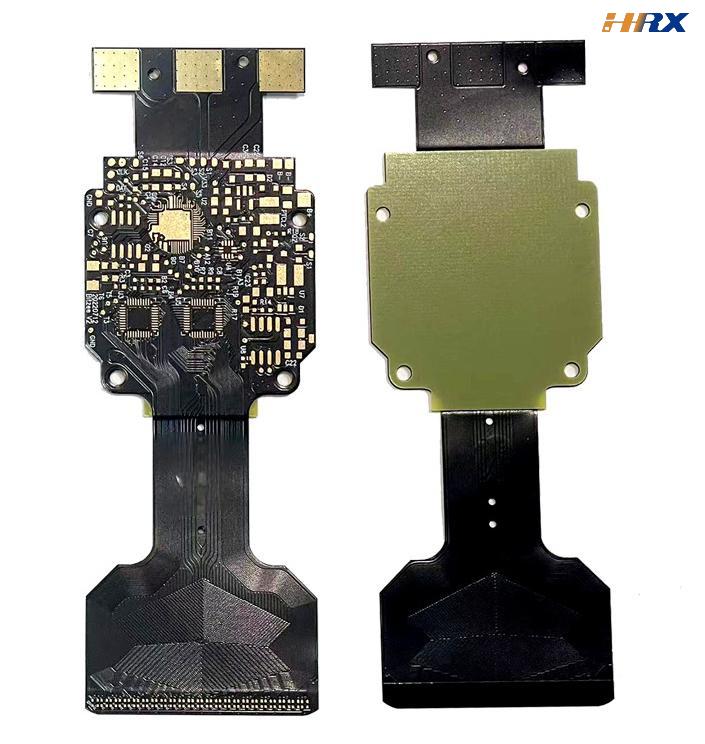

In the ever - evolving landscape of electronics manufacturing, rigid - flex printed boards (RFPCBs) have become an indispensable element, particularly in applications where space is severely constrained and high - performance interconnect solutions are demanded. Shenzhen Huaruixin Electronics Co., Ltd., a prominent provider specializing in the design and production of Flexible Printed Circuits (FPCs), Printed Circuit Boards (PCBs), and Rigid - Flex Printed Boards, boasts extensive expertise in this domain. Here, we will delve into strategies for optimizing the design of rigid - flex boards to significantly enhance production efficiency.

1. Understanding the Fundamentals of Rigid - Flex Boards

Rigid - flex boards artfully integrate the benefits of rigid PCBs and flexible FPCs. The rigid segments offer robust mechanical support and serve as a stable foundation for components that require a fixed platform. Meanwhile, the flexible portions, often crafted with advanced flexible substrates like Polyimide (PI), enable flexible routing, folding, and connection. This synergy results in a more compact and reliable design. However, it also presents unique challenges in both the design and manufacturing processes, such as managing differential impedance in high - speed signal lines and ensuring proper adhesion between rigid and flexible layers.

2. Design Considerations for Elevated Production Efficiency

Component Placement

Function - based Grouping: During the design of a rigid - flex board, it is of utmost importance to group components according to their functions. This approach not only streamlines the routing process but also simplifies manufacturing. For instance, all power - related components, such as capacitors, inductors, and voltage regulators, can be concentrated in one designated area, while signal - processing components like integrated circuits (ICs) and transistors can be placed in another. At Shenzhen Huaruixin Electronics Co., Ltd., our design team has developed a highly systematic methodology for component placement. By meticulously analyzing the electrical specifications of each component, including current ratings, voltage requirements, and signal frequencies, we can precisely determine the most optimal location for each component on the board. This ensures efficient power distribution, minimizes signal interference, and maximizes the overall performance of the board.

Avoiding Component Overcrowding: Overcrowding of components can lead to numerous difficulties in soldering, inspection, and repair processes. Adequate clearance between components should be maintained to facilitate easy access during manufacturing. Our engineers leverage state - of - the - art Computer - Aided Design (CAD) tools, such as Altium Designer and Cadence Allegro, to simulate the manufacturing process comprehensively. These tools can accurately identify potential overcrowding issues, such as insufficient solder mask clearance or overlapping component footprints, before the design is finalized. By addressing these issues early on, we can prevent costly production delays and ensure high - quality manufacturing.

Routing Design

Signal Path Simplification: Signal paths should be kept as short and straight as possible. This significantly reduces signal attenuation, minimizes electromagnetic interference (EMI), and simplifies the overall routing complexity. In rigid - flex boards, the flexible sections demand special attention. Our unique design philosophy at Huaruixin emphasizes minimizing the number of bends in the flexible areas while still satisfying the stringent electrical requirements. By carefully optimizing the routing in flexible regions, we can enhance the reliability of the board and accelerate the manufacturing process. For example, using serpentine routing techniques in the flexible sections can help manage signal length matching and impedance control without sacrificing flexibility.

Layer Stack - up Optimization: The layer stack - up of a rigid - flex board plays a pivotal role in its performance and manufacturability. By carefully selecting the number of layers, the type of materials (such as high - frequency laminates for RF applications), and the arrangement of power and ground planes, we can optimize the electrical characteristics of the board and simplify production. Our team possesses in - depth knowledge of various layer stack - up options, including single - sided, double - sided, and multi - layer configurations. We can recommend the most suitable solution based on the specific requirements of the project, such as signal integrity, power distribution, and cost - effectiveness.

Flex - Rigid Transitions

Smooth Transition Design: The transitions between the rigid and flexible sections of the board must be designed with great care to avoid stress concentration and potential failures. Rounded corners and gradual tapers should be employed in flex - rigid transitions. At Huaruixin, we have developed proprietary techniques for creating seamless flex - rigid transitions. These techniques ensure the long - term reliability of the board and simplify the manufacturing process. For example, using a combination of laser - ablated vias and flexible adhesives can improve the connection between rigid and flexible layers, reducing the risk of delamination.

Proper Reinforcement: Reinforcing the flex - rigid transitions with appropriate materials is crucial to enhance their mechanical strength. This can prevent cracking or delamination during both the manufacturing process and in - field use. Our engineers are well - versed in selecting the right reinforcement materials, such as fiberglass - reinforced polymers or metal - clad laminates, based on the specific application requirements. By choosing the optimal reinforcement materials, we can ensure the durability and reliability of the board in various operating conditions.

3. Our Professional Insights

Over the years, Shenzhen Huaruixin Electronics Co., Ltd. has observed that many design teams underestimate the significance of early collaboration between the design and manufacturing teams. By involving manufacturing experts from the initial design stage, potential issues related to Design for Manufacturability (DFM) can be identified and resolved more efficiently. Our in - house manufacturing team collaborates closely with the design team, providing valuable feedback on aspects such as component selection, layout optimization, and manufacturing process feasibility. This collaborative approach has enabled us to substantially reduce production lead times and improve the overall quality of our rigid - flex boards.

Another key aspect is our continuous investment in research and development to stay at the forefront of the industry. We have adopted cutting - edge manufacturing technologies, such as laser - direct structuring (LDS) for creating 3D conductive patterns on flexible substrates and high - precision pick - and - place machines for accurate component placement. These advanced technologies not only enhance the quality of our boards but also increase our production capacity, allowing us to meet the growing demands of our customers.

4. Contact Us

If you have any requirements or projects related to FPCs, PCBs, or Rigid - Flex Printed Boards, please do not hesitate to contact us. You can visit our website at www.hrxfpc.com or send an email to sales@hrxfpc.com. We also warmly welcome new and old friends to engage in communication and knowledge sharing. At Shenzhen Huaruixin Electronics Co., Ltd., we are committed to delivering high - quality products and excellent services to meet all your electronic manufacturing needs.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP