Search

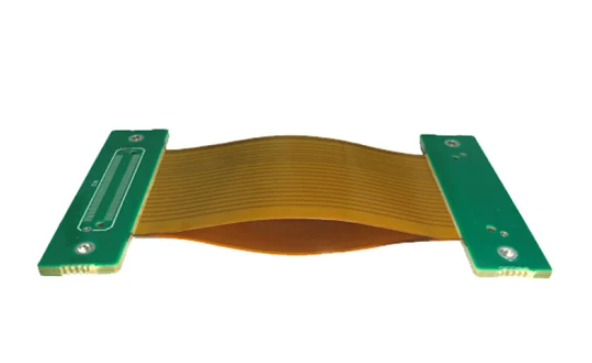

Loose-Leaf Designs to Improve Flexibility of Rigid-Flex PCB

- Oct 09,2023

-

Share

In the evolving landscape of electronics, flexibility is no longer just a desirable trait—it’s a necessity. Flexible Printed Circuits (FPC) and Rigid-Flex PCBs have become integral in the development of modern electronic devices, from wearable technology to aerospace applications. As these technologies advance, so too does the need for innovative design solutions that can improve their performance and adaptability. One such innovation is the Loose-Leaf design.

What is Loose-Leaf Design?

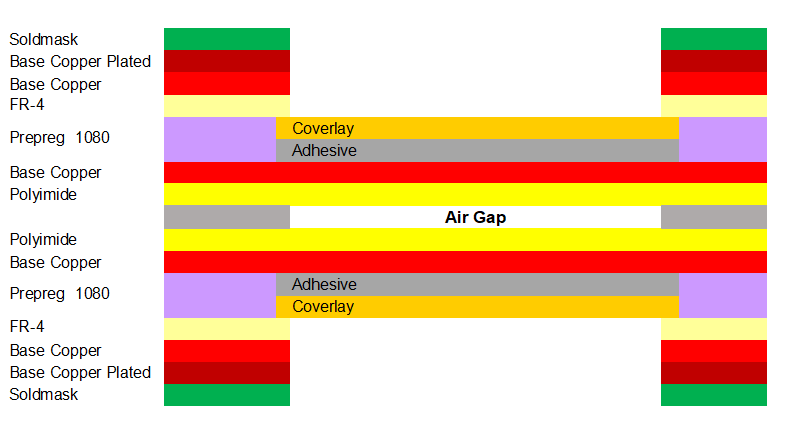

Loose-Leaf design is a novel approach that enhances the flexibility and durability of FPCs and Rigid-Flex PCBs. Unlike traditional designs, where layers of circuits are tightly bonded, the Loose-Leaf approach involves a partially bonded structure where certain layers are deliberately left unbonded or loosely attached. This configuration allows for greater mechanical flexibility, reduced stress on the circuits, and improved durability in dynamic applications.

Advantages of Loose-Leaf Design

1. Increased Flexibility: The primary advantage of the Loose-Leaf design is its ability to significantly increase the flexibility of the PCB. By leaving certain layers unbonded, the circuit can bend and flex more freely, making it ideal for applications where the board needs to be folded or subjected to continuous movement.

2. Reduced Mechanical Stress: Traditional multilayer PCBs can experience significant stress when bent, leading to potential failure points, especially at the layer interfaces. The Loose-Leaf design alleviates this by allowing layers to move independently, thereby reducing the mechanical stress and increasing the overall lifespan of the circuit.

3. Enhanced Durability: In applications where the PCB is exposed to constant movement or vibration, the Loose-Leaf design’s ability to absorb and distribute mechanical strain makes it more durable than fully bonded alternatives. This can be particularly beneficial in industries such as automotive, aerospace, and consumer electronics, where reliability is critical.

4. Improved Signal Integrity: By reducing the stress on individual layers, the Loose-Leaf design can also help maintain signal integrity. In tightly bonded designs, stress can cause microcracks or deformation, leading to signal degradation. The Loose-Leaf approach minimizes these risks, ensuring consistent performance.

Applications of Loose-Leaf Design

The Loose-Leaf design is particularly well-suited for applications where space constraints and mechanical flexibility are key considerations. Some of the notable applications include:

1. Wearable Devices: As wearable technology becomes more ubiquitous, the demand for flexible, durable, and compact PCBs has surged. Loose-Leaf designs can accommodate the unique form factors and continuous movement associated with wearable devices.

2. Aerospace and Automotive: Both of these industries require components that can withstand harsh conditions, including extreme temperatures, vibrations, and constant movement. The Loose-Leaf design’s enhanced durability and flexibility make it an ideal solution for such demanding environments.

3. Medical Devices: In the medical field, flexible PCBs are essential for devices that need to conform to the human body or operate within tight spaces. Loose-Leaf designs ensure that these devices can bend and flex without compromising functionality or reliability.

As the demand for flexible and reliable electronic components continues to grow, the Loose-Leaf design represents a significant advancement in the field of FPC and Rigid-Flex PCB technology. By enhancing flexibility, reducing mechanical stress, and improving durability, this innovative approach opens up new possibilities for design engineers and product developers across a wide range of industries.

Whether in the creation of cutting-edge wearable devices or in the development of robust aerospace systems, the Loose-Leaf design is set to play a crucial role in the future of electronics. As we continue to push the boundaries of what is possible, innovations like this will be key to meeting the challenges of tomorrow.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP