Search

Knife Molds or Steel Molds for FPC Production: Making the Right Decision

- Nov 07,2024

-

Share

In the domain of Flexible Printed Circuit (FPC) production, a crucial determination that both manufacturers and customers encounter is the choice between knife molds and steel molds. As a professional FPC producer, Shenzhen Huaruixin Electronics Co., Ltd. is highly aware of the significance of this selection and is here to guide you through the procedure.

Technology occupies a vital position in FPC production.

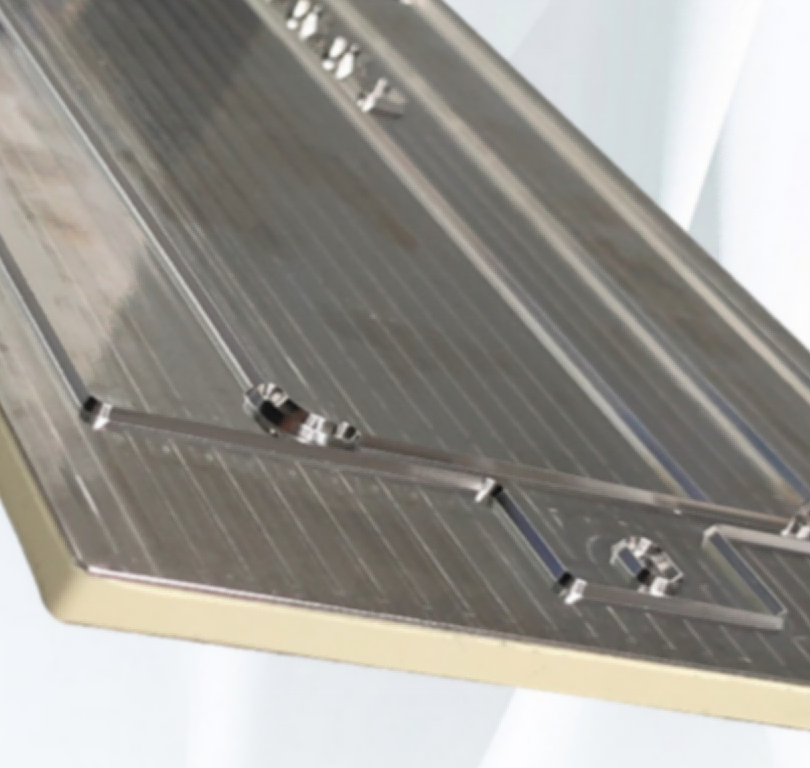

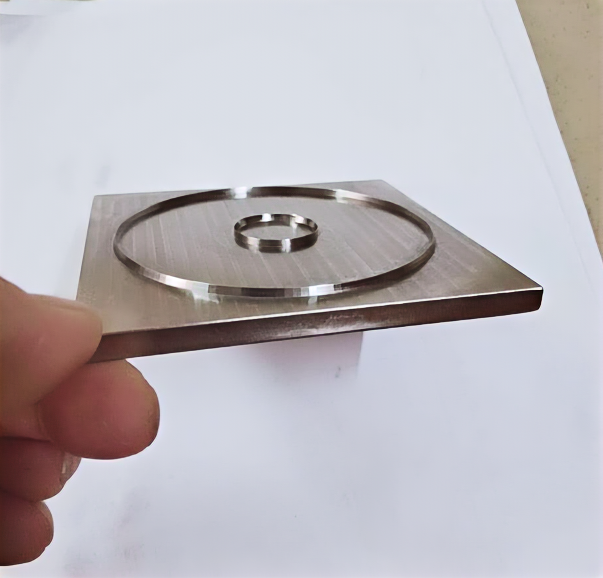

With the advancement of manufacturing processes, both knife molds and steel molds have their distinctive advantages. Knife molds are well-known for their flexibility and simplicity of customization. They can be promptly adjusted to fulfill the changing design requirements, making them suitable for projects that demand frequent modifications or small-scale production runs. On the contrary, steel molds provide superior precision and durability. Owing to advanced machining techniques, steel molds can manufacture FPCs with extremely narrow tolerances, guaranteeing consistent quality and performance.

Our extensive production experience at Shenzhen Huaruixin Electronics Co., Ltd. has enlightened us that the selection between knife molds and steel molds depends on several factors. From a customer's perspective, it is essential to take into account the specific requirements of your project. If you are looking for cost-effective solutions for short-term or prototype projects, knife molds might be the most appropriate choice. However, if you need high-volume production with strict quality control, steel molds could be the better alternative.

We understand that every customer is unique, and that is why we adopt an individualized approach to each project. Our team of experts works closely with customers to understand their requirements and recommend the most suitable mold option. We consider factors such as production volume, design complexity, and budget to ensure that you obtain the best outcomes.

At Shenzhen Huaruixin Electronics Co., Ltd., we are dedicated to providing high-quality FPCs and outstanding customer service. Whether you choose knife molds or steel molds, you can be confident that our state-of-the-art manufacturing facilities and experienced technicians will deliver products that meet your expectations.

So, if you are in the market for FPCs, come and negotiate and communicate with us. Let's discuss your project requirements and find the ideal solution for your needs. Shenzhen Huaruixin Electronics Co., Ltd. - your reliable partner in FPC production.

In the FPC industry, factors such as circuit density, layer count, and trace width also have an impact on determining the appropriate mold choice. Additionally, considerations like impedance control and solderability can affect the decision between knife molds and steel molds. Our expertise in these fields enables us to provide valuable insights and recommendations to our customers.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP