Search

Key Considerations in Customizing Flexible FPC for Advertising Screens from a Technical Perspective

- Dec 05,2024

-

Share

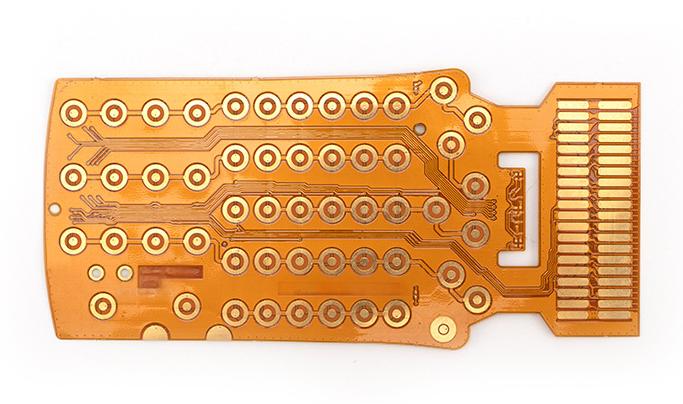

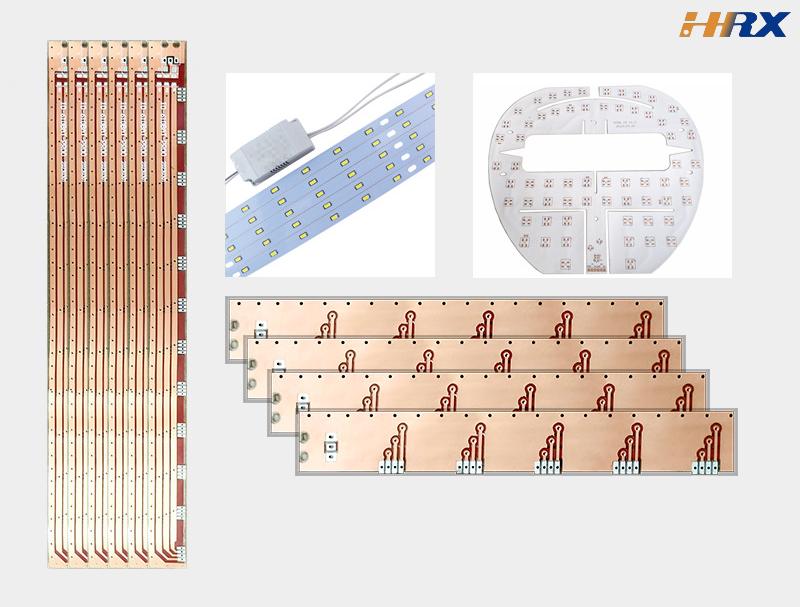

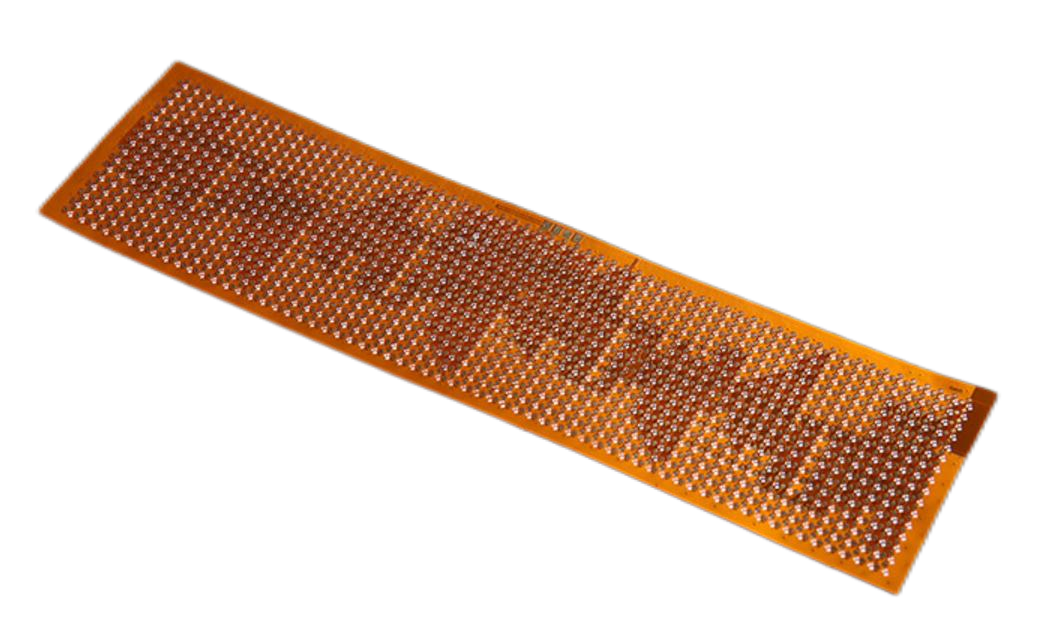

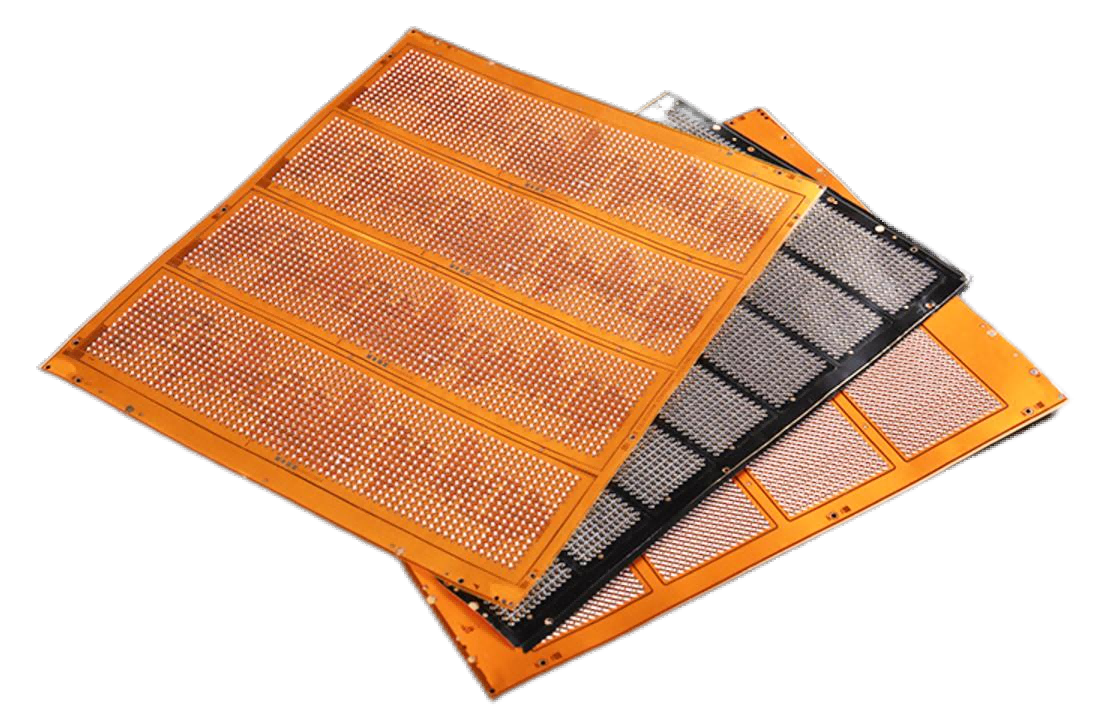

In the highly sophisticated and competitive domain of electronics, the customization of flexible FPC for advertising screens poses a distinct array of technical challenges and requisites. Shenzhen Huaruixin Electronics Co., Ltd., leveraging its profound expertise and extensive track record in FPC production and sales, is adept at surmounting these intricacies. From a technical engineer's vantage point, the following are the pivotal aspects that demand meticulous attention and astute consideration during the customization process.

1. Electrical Performance and Signal Integrity

The electrical attributes of the FPC constitute the bedrock for the seamless operation of the advertising screen. Paramount among these is the precise control of trace impedance. In high-resolution advertising screen applications, any impedance discrepancy can precipitate signal reflections and consequent degradation of image fidelity. For instance, in a project involving a 4K advertising display FPC, we were compelled to maintain an impedance tolerance within a stringent ±5 ohms across all signal conduits to guarantee pristine and lucid image transmission. Concurrently, the power distribution network must be engineered with finesse to accommodate the power demands of the profusion of LEDs or other display constituents. In a large-format outdoor advertising screen FPC, the power consumption can soar to several hundred watts. We incorporated wide power traces and a multiplicity of vias to curtail resistance and ensure a stable power supply, thereby precluding flickering or dimming artifacts in the display output.

2. Flexibility and Durability

Given the flexible nature of the FPC destined for advertising screens, which may be subjected to bending or curving during installation or operational phases, flexibility and durability emerge as cardinal attributes. The material selection wields a preponderant influence. We routinely deploy thin copper foils, typically in the 9 - 18 μm range, which strike an optimal equilibrium between conductivity and pliability. In a curved indoor advertising screen project, the FPC was mandated to endure repeated bending with a minimum radius of 10 mm. Through the utilization of a flexible polyimide substrate and a specialized adhesive laminate, the FPC was able to withstand over 10,000 bending cycles without incurring any fractures or disruptions in the conductive traces. Additionally, the FPC must exhibit resilience against environmental stressors such as humidity and temperature fluctuations. In an outdoor advertising screen application, we applied a protective encapsulation that could withstand temperature extremes spanning from -20°C to 60°C and elevated humidity levels, thereby safeguarding the long-term reliability and functionality of the FPC.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP