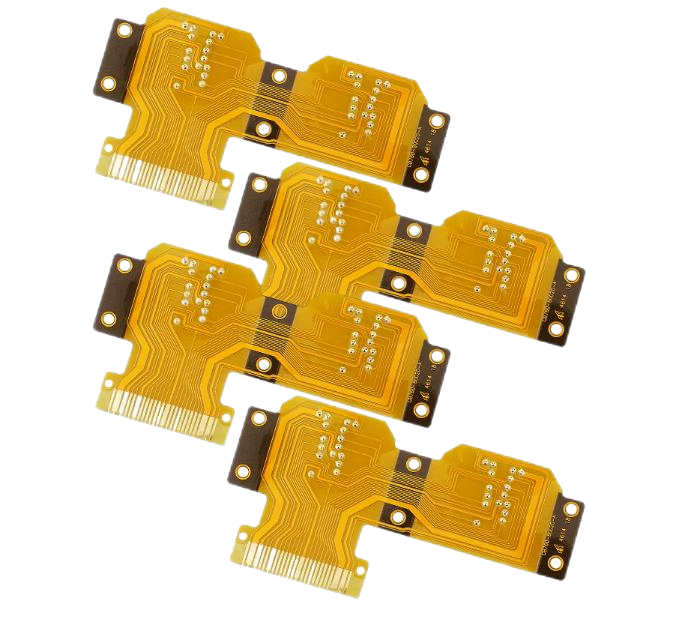

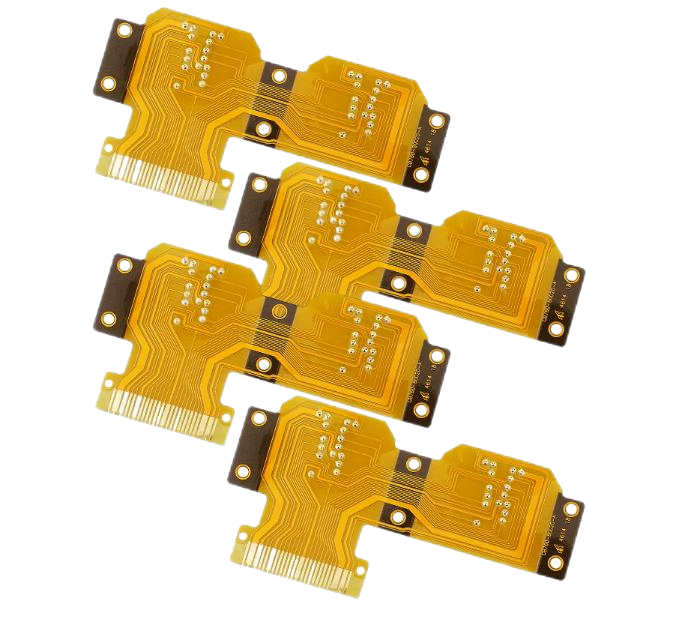

In the highly specialized domain of electronics manufacturing, the production of printer cartridge FPC (Flexible Printed Circuit) flexible cables stands as a complex and exacting task.

Shenzhen Huaruixin Electronics Co., Ltd., a renowned professional FPC manufacturer with a wealth of experience, has mastered the art of navigating through the numerous challenges inherent in this process. Here, we will spotlight the critical issues that demand meticulous attention during production and present effective strategies to avert them.

1. Material Selection: The Cornerstone of Quality

The selection of appropriate materials is non-negotiable and forms the very foundation of a successful FPC production. High-caliber base films and conductive materials are of utmost importance. Substandard materials can precipitate a host of problems, including compromised flexibility, susceptibility to breakage, and erratic electrical conductivity. To circumvent such issues, an uncompromising quality control regime must be instituted during the procurement phase. Suppliers should be subject to a rigorous vetting process, and only materials that not only adhere to industry benchmarks but also precisely match the specific product requisites should be greenlit. For instance, a base film with an optimal thickness and tensile strength is the linchpin in ensuring that the FPC can endure the incessant bending and mechanical stresses endured during the installation and operational lifespan of the printer cartridge.

2. Circuit Design and Layout: Precision Engineering

Accurate and astute circuit design and layout are the bedrock of a functionally sound FPC. The circuitry must be finetuned to flawlessly meet the electrical connection imperatives of the printer cartridge. Any lapses in the design can give rise to signal interference, short circuits, or open circuits, which can render the entire product inoperable. Design engineers should harness the power of state-of-the-art software tools for comprehensive simulation and verification prior to commencing production. Moreover, ample clearance and isolation must be maintained between disparate circuits to stave off crosstalk. As an illustrative example, in the layout of power and signal lines, meticulous spacing and effective shielding measures must be implemented to safeguard the integrity and stability of signal transmission.

3. Manufacturing Process Control: The Heart of Consistency

During the manufacturing odyssey, several pivotal aspects mandate unwavering attention.

Etching Process: The Fine Line of Precision

The etching process is a delicate dance that demands pinpoint accuracy. Over-etching or under-etching can precipitate catastrophic consequences such as broken traces or residual copper, which can cripple the functionality of the FPC. Regular and meticulous inspection, coupled with precise calibration of etching equipment, is the sine qua non for upholding the consistency and exactitude of the etching process.

Lamination Process: The Art of Bonding

The lamination of diverse layers is a highly sensitive operation that hinges on strict adherence to temperature, pressure, and time parameters. Any deviation from the optimal conditions can lead to delamination or the formation of air bubbles between layers, thereby undermining the mechanical and electrical robustness of the FPC. Real-time monitoring and astute adjustment of lamination parameters are the keys to preempting these potential disasters.

Soldering Process: The Heat of Connection

In the soldering of connectors and components, the temperature and soldering duration must be calibrated with surgical precision. Excessive heat can inflict irreparable damage on the FPC or its constituent components, while inadequate soldering can spawn unreliable connections that jeopardize the overall performance. Employing advanced soldering equipment endowed with temperature control and vigilant monitoring capabilities is not an option but an absolute necessity.

4. Quality Inspection and Testing: The Final GatekeeperComprehensive and exhaustive quality inspection and testing serve as the ultimate bulwark against defective products. Visual inspection, electrical testing, and reliability testing should be conducted with the utmost rigor. Visual inspection can unearth blatant defects such as scratches, cracks, and foreign matter marring the surface of the FPC. Electrical testing encompasses continuity testing, insulation resistance testing, and impedance testing, all of which are essential for certifying the electrical prowess of the circuit. Reliability testing, including temperature cycling testing and vibration testing, is the litmus test for evaluating the durability and stability of the FPC under a gamut of environmental conditions. Any subpar products must be promptly identified and expeditiously removed to safeguard the unimpeachable quality of the final offering.

In summation, the production of printer cartridge FPC flexible cables is a multifaceted and arduous endeavor. By zeroing in on material selection, circuit design and layout, manufacturing process control, and quality inspection and testing, and implementing corresponding preventive measures with unwavering resolve, high-quality FPC products can be churned out to satiate the voracious demands of the printer cartridge market.

Shenzhen Huaruixin Electronics Co., Ltd. is ever-eager to engage in fruitful communication and collaboration with new and old customers, with the shared objective of ceaselessly enhancing and innovating in the realm of FPC production.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.