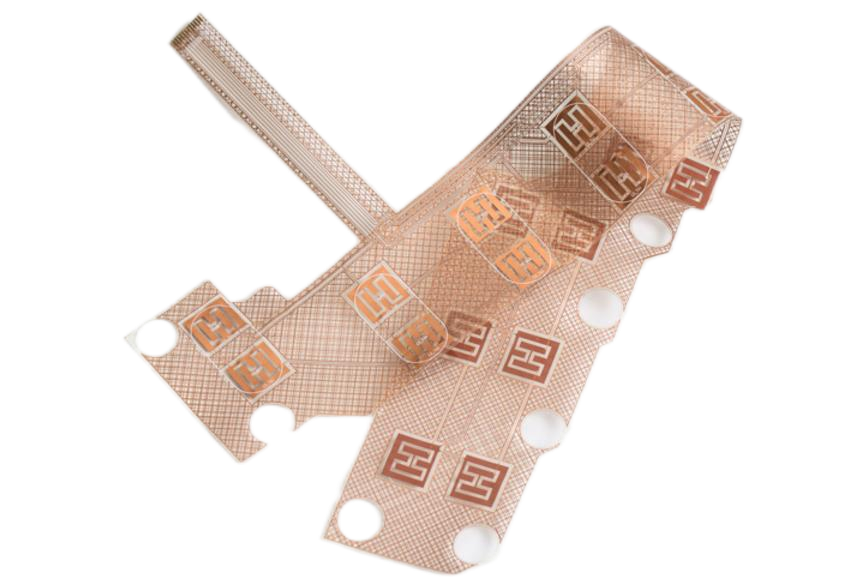

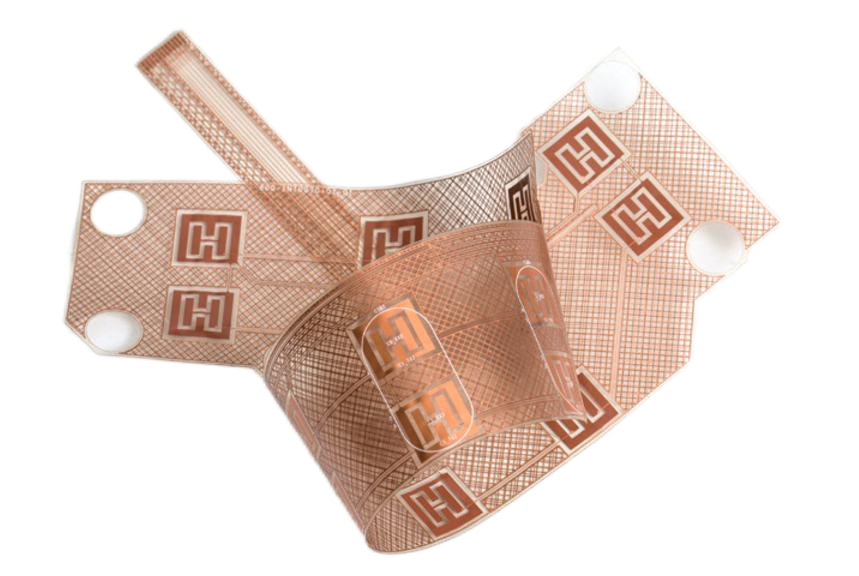

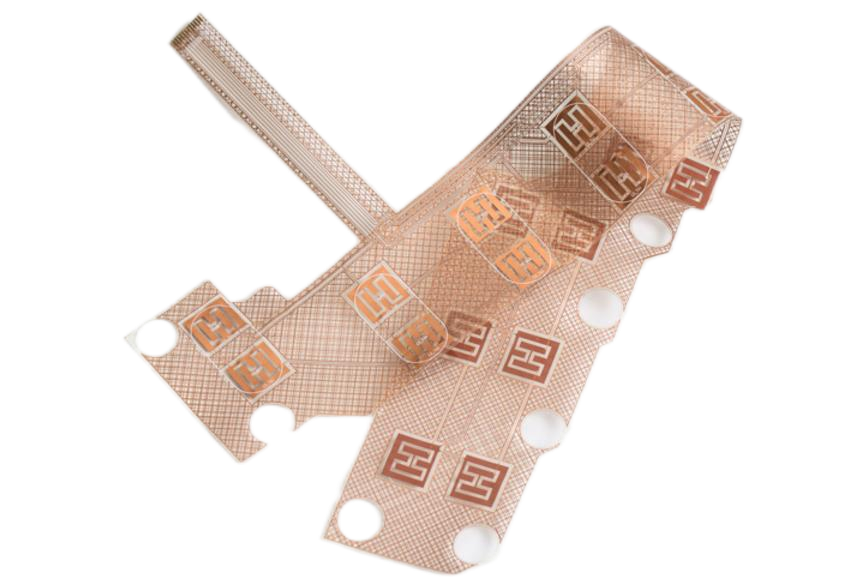

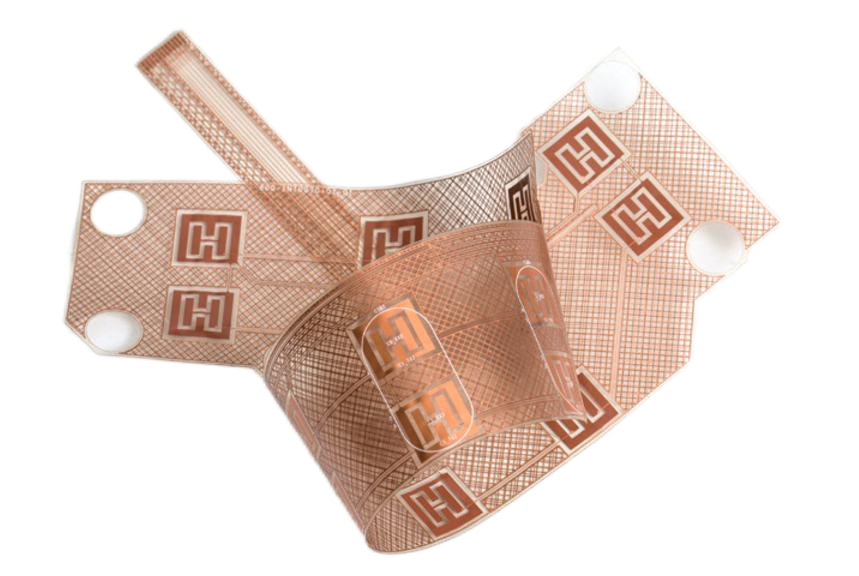

As a technical engineer immersed in the intricate domain of electronics, the customization of double-sided transparent FPC (Flexible Printed Circuit) and ultra-thin PET (Polyethylene Terephthalate) flexible circuit boards mandates a profound and comprehensive comprehension of a multitude of cardinal aspects.

Key Considerations:

1. Material Compatibility and Adhesion Kinetics:

When grappling with double-sided transparent FPCs and ultra-thin PET substrates, ensuring the harmonious compatibility of materials is not only vital but also demands a profound understanding of adhesion kinetics. The adhesive deployed to bond disparate layers, such as the conductive traces and the PET film, must possess superlative adhesion characteristics and refrain from instigating any deleterious chemical reactions that could potentially degrade the performance or aesthetic allure of the board. For instance, certain adhesives might exhibit embrittlement over time or under specific temperature and humidity regimens, precipitating delamination quandaries.

2. Trace Precision and Microfabrication:

The exactitude of the conductive trace layout assumes a preponderant role. The width and spacing of the traces mandate precise control to satiate the electrical requisites. In double-sided designs, the alignment congruence between the top and bottom traces during the manufacturing process poses a formidable challenge. Even a minuscule misalignment can engender electrical shorts or open circuits. Consequently, state-of-the-art microfabrication techniques and stringent quality control protocols are indispensably requisite to safeguard the integrity of the traces.

3. Flexibility and Durability: Mechanical and Material Resilience:

These ultra-thin and pliable circuit boards are engineered to endure repeated bending and folding in sundry applications. However, maintaining their durability whilst permitting flexibility represents a precarious equipoise. The material selection and manufacturing modus operandi ought to be optimized to ensure that the board can withstand a substantial number of bending cycles without succumbing to cracking or forfeiting its electrical conductivity. For example, the choice of copper thickness and the caliber of the flexible substrate play a preponderant role in dictating the flexural endurance and mechanical resilience of the FPC.

4. Optical Clarity and Photonic Compatibility:

For double-sided transparent FPCs, optical clarity is a sui generis desideratum. The transparency of the board should not be appreciably compromised by the presence of conductive traces and other constituents. This demands a meticulous selection of materials and manufacturing processes that minimize any scattering or absorption of light. Specialized coatings or treatments might be obligatory to augment the optical properties while concurrently preserving the electrical functionality and photonic compatibility.

Application Areas:

1. Consumer Electronics: Mobile and Portable Device Integration:

In smartphones and tablets, these flexible circuit boards are ubiquitously employed to establish connections among diverse components such as the display, touch panel, and motherboard. Their flexibility endows the devices with more compact and ergonomic designs, facilitating thinner bezels and foldable functionalities. For example, in a foldable smartphone, the double-sided transparent FPCs can be deployed to route signals between the two halves of the display, ensuring seamless operation during folding and unfolding maneuvers.

2. Wearable Devices: Bio-Integrated and Conformal Electronics:

Wearables like smartwatches and fitness trackers hinge on the flexibility and diminutive size of these circuit boards. They are utilized to interconnect sensors, batteries, and processors within the constricted space of the device. The ultra-thin PET flexible circuit boards can adaptively conform to the curved surfaces of the wearable, proffering a comfortable wearing experience for the user. Moreover, the transparency can confer an advantage in certain designs where aesthetics and the visibility of underlying components are of paramount significance.

3. Medical Equipment: Biomedical Sensing and Implantable Technologies:

In medical devices such as portable monitors and implantable sensors, the flexibility and biocompatibility of these FPCs are of cardinal importance. They can be enlisted to connect electrodes and sensors to the principal control unit. The double-sided transparent feature might prove invaluable in some optical sensing applications within medical equipment, permitting enhanced integration of light-based sensors and signal transduction.

4. Automotive Electronics: Vehicular Connectivity and ADAS Integration:

With the burgeoning trend of in-car electronics and advanced driver-assistance systems (ADAS), these flexible circuit boards find extensive applications in interconnecting sensors, cameras, and control units. Their capacity to withstand the rigors of the automotive environment, encompassing temperature oscillations and vibrations, renders them eminently suitable for deployment in dashboards, door panels, and under-hood electronics.

In summation, customizing double-sided transparent FPC and ultra-thin PET flexible circuit boards entails surmounting a plethora of technical hurdles.

Shenzhen Huaruixin Electronics Co., Ltd., armed with its copious experience in FPC production and sales, is optimally positioned to navigate these complexities. We cordially welcome new and old customers to partake in erudite discussions and collaborative learning to further excavate the latent potential of these innovative circuit board technologies and their variegated application areas.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.