Search

How to Reduce the Cost of LED Light Boards

- Apr 08,2025

-

Share

In the highly competitive LED lighting market, cost control is of utmost importance for a company's competitiveness and profitability. As a professional manufacturer specializing in the design and production of FPC&PCB&Rigid - Flex Printed Boards, Shenzhen Huaruixin Electronics Co., Ltd. brings unique insights and proven solutions to help our customers reduce the cost of LED light boards, drawing on our years of accumulated expertise and rich experience.

I. Material Selection and Optimization

(A) PCB Substrate Materials

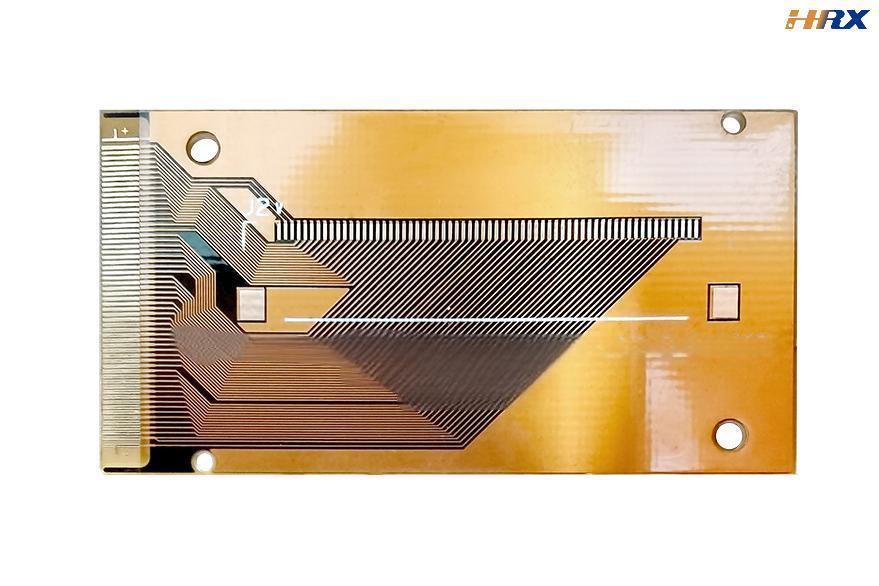

Advantages of FPC

We are well - aware of the remarkable advantages of FPC (Flexible Printed Circuit) in LED light board applications. FPC offers excellent heat dissipation and solderability, and is easy to assemble and connect. It uses an additive process, and the cost of the base material is low. The cost of the polymer thick - film circuit is only 1/10 of the price of the copper - polyimide film circuit and 1/2 - 1/3 of the price of the rigid circuit board. For instance, in some LED light strip products with specific requirements for space layout and flexibility, we recommended the use of FPC substrates to our customers. This not only met the special design needs of the products but also significantly reduced material costs, enhancing the price competitiveness of the products in the market.

Aluminum - based PCB

For LED light boards with high power and demanding heat dissipation requirements, such as those used in some outdoor and industrial lighting products, aluminum - based PCB is an ideal choice. Although the unit price of aluminum - based PCB is relatively higher than that of traditional rigid PCB, considering the overall cost, its excellent heat dissipation performance can reduce the use of additional heat dissipation devices and simultaneously extend the service life of LED lamp beads, reducing maintenance costs. Take the LED light board solution we provided for an outdoor lighting fixture manufacturer as an example. After using aluminum - based PCB, the failure rate of the customer's products was significantly reduced, and the overall cost was effectively controlled over the product's life cycle.

(B) LED Lamp Beads

Rational Selection

The cost of LED lamp beads accounts for a large proportion of the total cost of LED light boards. Therefore, rational selection is crucial. We will provide customers with the best lamp bead selection suggestions based on their performance requirements for LED light boards, such as brightness, color, and lifespan, combined with the characteristics and prices of different lamp beads. For example, for some ordinary lighting scenarios with low requirements for color rendering index, cost - effective domestic lamp beads can be selected to replace imported ones, effectively reducing costs while meeting basic lighting needs. At the same time, we also remind customers to pay attention to the quality parameters of lamp beads, such as electrostatic resistance, wavelength consistency, and leakage current, to avoid product quality problems and increased after - sales costs due to the use of inferior lamp beads.

High - Voltage Chip Solution

In the field of Mini LED applications, using high - voltage chips is an effective cost - reduction method. High - voltage chips have a smaller driving current, higher luminous efficiency, and fewer series - connected LED beads, making PCB board wiring more convenient. We maintain close cooperation with multiple chip manufacturers to jointly develop high - voltage chip solutions for our customers. For example, in the Mini LED light board solution provided for a display manufacturer, high - voltage chips were used, which not only reduced the number of lamp beads and the difficulty of PCB wiring but also improved the overall performance and stability of the light board, helping the customer gain an edge in the market competition.

II. Design Optimization

(A) Circuit Design

Simplify the Circuit

By optimizing the circuit design and reducing unnecessary electronic components, both material costs and production process complexity can be reduced. Our professional circuit design team conducts in - depth analysis of the circuit during the design of LED light boards, removing redundant parts to ensure that the circuit structure is the simplest while meeting electrical performance requirements. For example, in some simple LED lighting circuits, by reasonably designing the power module, the number of filter capacitors and voltage - regulating diodes was reduced, effectively reducing costs.

Integrated Lamp - Driver Design

Integrating the driver circuit with the LED light board, that is, the integrated lamp - driver design, can reduce the overall volume and weight, as well as material and assembly costs. When designing the LED light board for a smart home lighting product, we adopted an integrated lamp - driver solution, skillfully arranging the driver circuit on the LED light board. This not only made the product appearance more concise and beautiful but also reduced connecting wires and additional driver enclosures, reducing the production cost for the customer by approximately 20%.

(B) PCB Layout Design

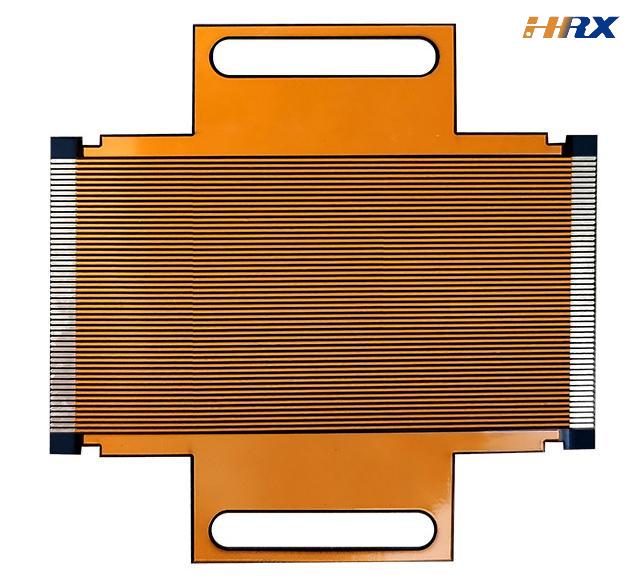

Fish - bone - shaped PCB

In the design of Mini LED light boards, the fish - bone - shaped PCB is an effective cost - reduction layout method. This design can reduce the PCB board area, improve the utilization rate of a single board, and at the same time reduce the PCB accuracy requirements, thus reducing manufacturing costs. The Mini LED light boards we provided for several TV manufacturers adopted the fish - bone - shaped PCB design, reducing the PCB manufacturing cost by approximately 30% and significantly improving the yield rate.

Reduce the Number of PCB Layers

Under the premise of meeting electrical performance and signal transmission requirements, try to reduce the number of PCB layers. Each additional PCB layer will significantly increase material and manufacturing process costs. By optimizing circuit layout and signal wiring, we have helped customers successfully change some LED light boards originally designed with multi - layer PCBs to double - layer or four - layer PCBs, effectively reducing costs while ensuring product performance.

III. Production Process Improvement

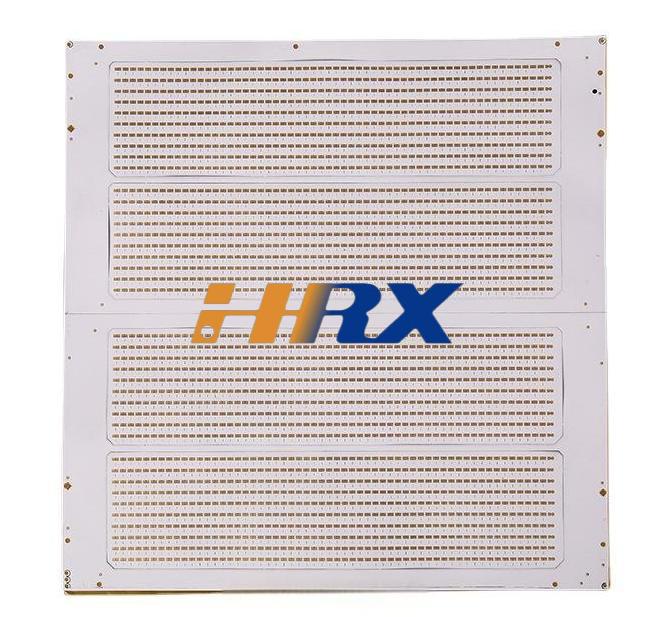

(A) Secondary Printing of White Solder Mask

For LED light board products with high reflectivity requirements, we adopt a process solution of secondary printing of white solder mask. This solution can reduce the use of high - value ink materials while ensuring reflectivity. For example, in the production of a high - end LED lighting fixture's light board, by implementing the secondary printing of white solder mask process, the ink cost was reduced by approximately 40%, and the product's reflective effect reached the leading level in the industry.

(B) Laser Window - Opening Solution

In response to the problem of solder mask ink side - etching that easily occurs in the production of LED light boards, we introduced a laser window - opening solution. This solution can accurately control the size and position of the window, ensuring product yield and reducing production costs. In actual production, after adopting the laser window - opening solution, the product yield rate increased from the original 85% to over 95%, greatly reducing the cost waste caused by defective products.

IV. Supply Chain Management and Cooperation

(A) Long - term and Stable Cooperation

We have established long - term and stable cooperative relationships with numerous high - quality raw material suppliers. Through large - scale procurement and strategic cooperation agreements, we can obtain more favorable purchase prices. At the same time, stable cooperative relationships also help ensure the quality and supply stability of raw materials, reducing production delays and cost increases caused by raw material shortages or quality problems. For example, we signed an annual purchase agreement with a well - known lamp bead supplier, reducing the purchase price by 15% - 20% while ensuring the quality of lamp beads.

(B) Collaborative R & D

We actively carry out collaborative R & D with customers and suppliers, jointly exploring new materials, designs, and processes to achieve the dual goals of cost reduction and performance improvement. In a cooperation project with a large - scale lighting enterprise, we jointly developed a new type of LED light board material with the customer and the supplier. This material reduced the cost by approximately 30% while meeting the product performance requirements, bringing significant economic benefits to the customer.

Shenzhen Huaruixin Electronics Co., Ltd., with its professional technical team, rich industry experience, and in - depth understanding of cost control, can provide customers with comprehensive cost - reduction solutions for LED light boards by taking effective measures in material selection, design optimization, production process improvement, and supply chain management, helping customers gain an advantage in the market competition.

If you have any needs or projects, please feel free to contact us. Welcome to visit our website: www.hrxfpc.com for more information or send an email to sales@hrxfpc.com for inquiries.

We also welcome new and old friends to communicate and learn together.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP