How to Choose the Right Surface Treatment for Rigid - flex Boards: A Customer - oriented Guide

- Nov 19,2024

-

Share

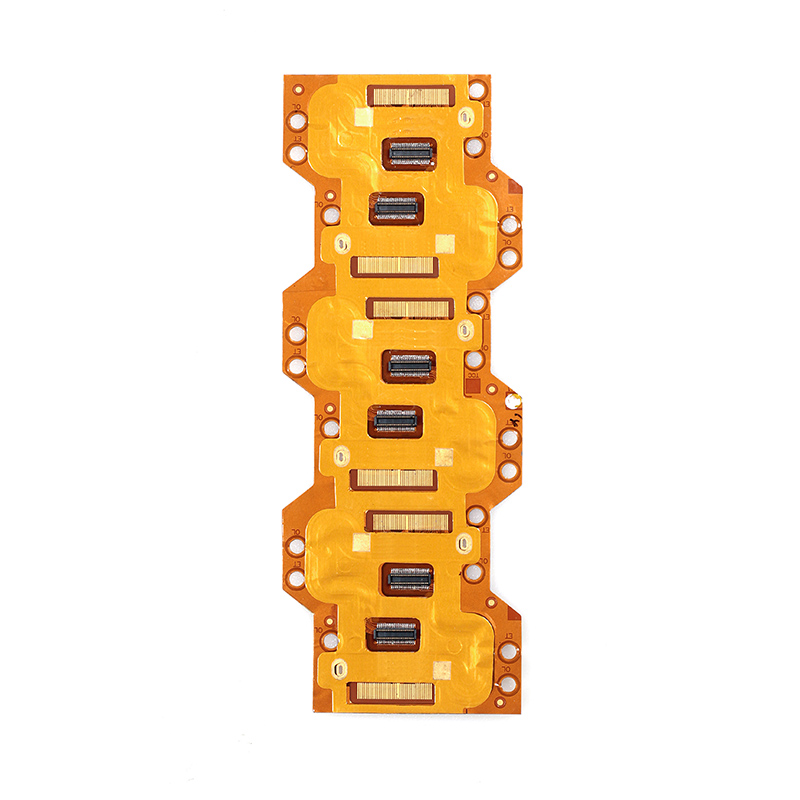

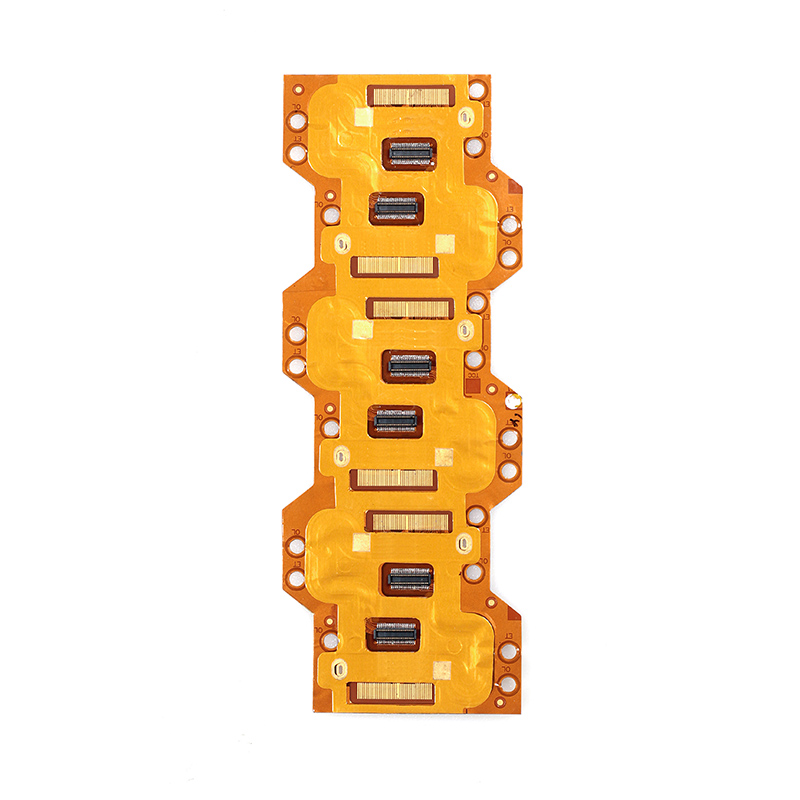

When it comes to Rigid - flex Board production, choosing the appropriate surface treatment is crucial for the performance and quality of your final product. Here at Shenzhen Huaruixin Electronics Co., Ltd., a specialized FPC production and sales company, we understand your concerns. In this blog, we'll help you make an informed decision by discussing various factors, along with some successful design cases.

1. Soldering Performance

Fine - pitch Component Soldering: If your Rigid - flex Board has numerous fine - pitch electronic components, like high - density integrated circuit chips, you need a surface treatment that enables precise soldering. Electroless nickel - immersion gold (ENIG) is an excellent choice. The flat and uniform gold layer it provides significantly reduces the risks of short circuits and cold joints during soldering. For instance, in smartphone motherboards and high - end server circuit boards, where the precision of soldering is of utmost importance, the ENIG process ensures reliable connections between signal pins.

General Component Soldering: For Rigid - flex Boards with relatively large - spaced components and less demanding soldering requirements, the Hot - Air Solder Leveling (HASL) lead - free process usually suffices. It offers good solderability for most common components at a relatively lower cost. For example, in simple industrial control boards with discrete components, HASL lead - free can effectively complete the soldering task.

2. Electrical Performance

High - frequency Signal Transmission: In Rigid - flex Boards handling high - frequency signals such as radio - frequency circuits or high - speed digital signal circuits, the surface treatment greatly affects signal integrity. ENIG, with its stable gold layer and low roughness, provides better signal transmission performance, reducing signal reflection and loss. In contrast, the HASL lead - free surface, due to its slightly inferior flatness, may cause some interference to high - frequency signals. For example, in the RF modules of 5G communication equipment, the ENIG treatment helps maintain the quality of high - frequency signals.

Electrical Connection Reliability: For applications requiring long - term stable electrical connections, like in aerospace and automotive electronics, corrosion resistance and stability of contact resistance are key. The ENIG process has strong anti - corrosion capabilities and can maintain a low contact resistance under harsh conditions, ensuring the reliability of electrical connections. Although the HASL lead - free process has relatively weaker performance in this regard, it can still meet basic electrical connection requirements in less demanding environments.

3. Mechanical Performance

Flexibility Requirement: Rigid - flex Boards have both rigid and flexible parts. In the flexible areas, the flexibility of the surface treatment layer needs to be considered. Some flexible HASL lead - free processes or special surface treatment materials can meet this requirement to some extent while providing necessary soldering performance. This helps prevent cracking or peeling of the surface treatment layer during bending or folding.

Wear Resistance: If the Rigid - flex Board may be subject to mechanical actions like friction or frequent insertion and extraction during use, the wear resistance of the surface treatment layer is important. The relatively hard gold surface of the ENIG process has good wear resistance, making it suitable for circuit boards with frequently plugged - in interfaces, such as the area near the USB ports on a computer motherboard.

1. Chemical Environment

Corrosive Environment: If your Rigid - flex Board will be exposed to a humid environment, chemical corrosive gases (like industrial exhaust gases, salt - fog environments), or chemical liquids (such as engine oil and coolant near a car engine), the anti - corrosion advantage of the ENIG surface treatment becomes very prominent. It effectively prevents the copper layer from being corroded and extends the service life of the circuit board. For example, in marine environment monitoring equipment or chemical production equipment, the ENIG treatment is essential for the long - term stable operation of the Rigid - flex Board.

General Environment: For Rigid - flex Boards used in relatively dry and clean indoor environments, such as those inside ordinary office equipment or consumer electronics, the HASL lead - free process may be sufficient as the risk of corrosion is relatively low.

2. Temperature Environment

High - temperature Environment: In high - temperature environments (such as inside a car engine compartment or near industrial furnaces), the surface treatment layer needs to withstand high temperatures without performance degradation. Some high - temperature - stable ENIG processes or special - formula HASL lead - free processes with good thermal stability can be selected. At the same time, it's necessary to consider the thermal expansion coefficient matching of different materials at high temperatures to avoid delamination or cracking between the surface treatment layer and the substrate.

Temperature - varying Environment: For Rigid - flex Boards experiencing frequent temperature changes, such as outdoor electronic equipment or aerospace equipment, a surface treatment method with good thermal stress adaptability should be chosen. The ENIG process performs well in this case due to its good adhesion and relatively stable physical properties. However, attention should also be paid to the thickness design of the nickel and gold layers to cope with the stress caused by thermal cycling.

1. Material Cost

The chemical materials used in the ENIG process, such as nickel salts and gold salts, are relatively expensive, which makes the material cost of ENIG - treated Rigid - flex Boards significantly higher than that of HASL lead - free ones. In large - scale production, the difference in material cost can have a significant impact on the total cost of the product. For example, in cost - sensitive consumer electronics like ordinary smartwatches and low - end mobile phones, material cost is an important consideration.

2. Processing Cost

The ENIG process usually involves multiple complex chemical plating and cleaning steps, requiring more precise equipment and strict process control, resulting in higher processing costs. On the other hand, the HASL lead - free process is relatively simple, with lower equipment requirements and processing difficulty, and thus lower processing costs. In cases of small - batch production or strict cost control, processing cost is also an important factor in determining the surface treatment method.

1. Existing Production Equipment and Process Capabilities

If your production facility already has mature HASL lead - free production equipment and process experience, considering the HASL lead - free process first, provided it meets the product performance and usage environment requirements, can reduce equipment investment and process adjustment costs. Conversely, if your factory has technical advantages and equipment resources in the ENIG process, it may be a better choice.

2. Compatibility with Subsequent Processing and Assembly Processes

After surface treatment, the Rigid - flex Board will undergo other processing steps such as component installation and packaging. The surface treatment method needs to be compatible with these subsequent processes. For example, some packaging processes may have specific requirements for surface flatness and chemical activity, which requires selecting a surface treatment method that can meet these requirements. In automated production lines, the surface - treated Rigid - flex Board needs to smoothly pass through automatic soldering equipment, inspection equipment, etc., which also demands the consistency and compatibility of the surface treatment.

1. Smartphone Motherboard Project

At Shenzhen Huaruixin Electronics, we produced a smartphone motherboard Rigid - flex Board. Considering the large number of fine - pitch components and high - speed signal transmission requirements, we chose the ENIG surface treatment. The gold layer provided excellent solderability for the CPU, memory chips, and other key components. It also ensured stable high - speed signal transmission between different chips, contributing to the high - performance operation of the smartphone.

2. Automotive Engine Control Unit Rigid - flex Board

For an automotive engine control unit, the Rigid - flex Board needed to withstand high temperatures, chemical exposure, and mechanical vibrations. We adopted a combination of HASL lead - free for some areas with less critical requirements and ENIG for the key components and connectors. The HASL lead - free part handled general power supply and signal connections, while the ENIG part ensured reliable operation of the control unit's core components in the harsh automotive environment.

3. Industrial Monitoring Equipment Rigid - flex Board

In an industrial monitoring equipment project, the Rigid - flex Board was used in a corrosive and temperature - varying environment. We selected the ENIG surface treatment for the entire board. The excellent corrosion resistance and stable electrical performance of ENIG allowed the board to operate reliably in the industrial environment, accurately collecting and transmitting monitoring data.

We hope this information helps you make the best decision for your Rigid - flex Board surface treatment. At

Shenzhen Huaruixin Electronics Co., Ltd., we are always here to communicate, discuss, and learn together with our new and old customers.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.