Search

How Copper Foil Thickness Affects FPC Performance

- Dec 18,2024

-

Share

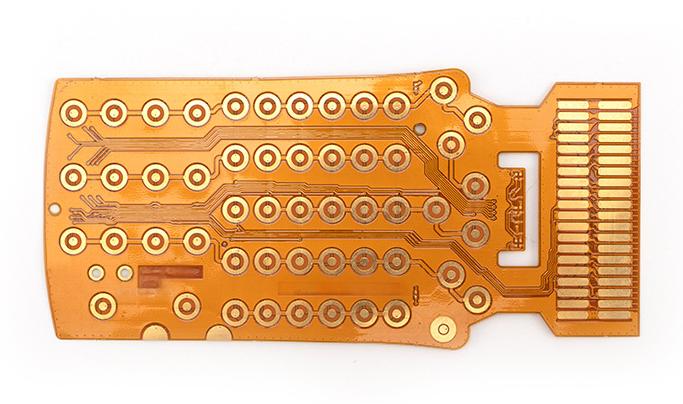

In the realm of Flexible Printed Circuits (FPCs), the thickness of copper foil emerges as a pivotal determinant that profoundly influences the performance attributes of the end product. Shenzhen Huaruixin Electronics Co., Ltd., a preeminent and highly proficient manufacturer and vendor of FPCs with a wealth of accrued experience, is intimately acquainted with these intricate nuances. Let's embark on an in-depth exploration of how copper foil thickness impinges upon FPC performance and some attendant considerations.

1. Conductivity

The thickness of copper foil is directly proportional to its cross-sectional area. In accordance with the resistivity formula (where represents resistance, signifies resistivity, denotes the length of the conductor, and stands for the cross-sectional area), when the length and material remain constant (with identical resistivity ), a thicker copper foil invariably results in a diminished resistance. For instance, in high-power FPCs deployed in the battery management system of electric vehicles, which mandate substantial current-carrying capacity, a thicker copper foil is indispensable. This is because it effectively curtails the line resistance. By virtue of Joule's law (where symbolizes heat generation, represents current, is resistance, and is time), a reduction in resistance concomitantly leads to a decrease in heat production for a given current and time . This not only augments the energy efficiency of the FPC but also mitigates the potential for line damage or performance deterioration due to overheating. Conversely, a thinner copper foil, characterized by a relatively larger resistance, is more aptly suited for low-current signal transmission lines. A prime example is the FPCs incorporated in diminutive consumer electronics such as smartwatches, where only feeble control signals are transmitted. In such scenarios, a thinner copper foil suffices to fulfill the signal transmission requisites while concomitantly conferring a sleeker and more lightweight profile to the FPC.

2. Mechanical Properties

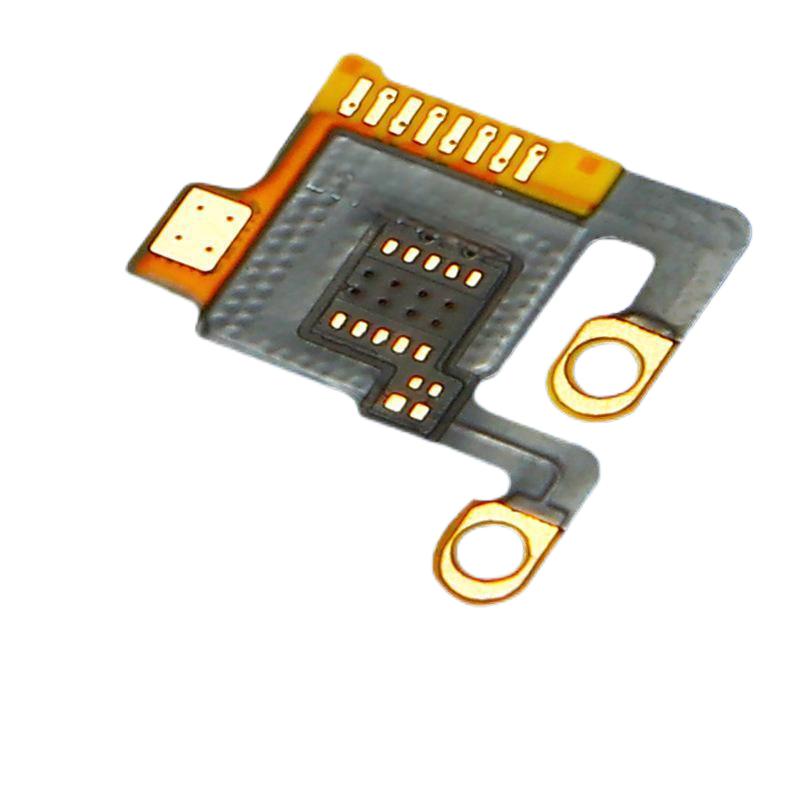

Thick copper foil endows the FPC with enhanced mechanical robustness. In applications where the FPC is subjected to appreciable mechanical stresses, such as in the connector FPCs of laptops that endure frequent plugging and unplugging operations, a thicker copper foil exhibits superior resistance to the tensile and frictional forces engendered during these processes. This effectively diminishes the likelihood of copper foil rupture. In contrast, a thinner copper foil is inherently more fragile and prone to fracturing under external mechanical loads. Nevertheless, it offers the advantage of enhanced flexibility, rendering it highly suitable for FPC applications that entail recurrent bending. Consider, for example, wearable devices like smart bracelets. The thin copper foil in such FPCs can gracefully adapt to the device's bending motions without incurring damage, provided the bending amplitude remains within its tolerance limits.

3. Processing Technology

The etching process for thick copper foil demands a more protracted duration. Since etching involves the removal of superfluous copper foil through a chemical solution, a thicker copper foil necessitates the etching away of a greater volume of copper material. This mandates the meticulous adjustment of etching process parameters, including etching solution concentration, etching time, and etching temperature, in strict accordance with the copper foil thickness. For instance, a thicker copper foil might require a higher concentration of etching solution or an extended etching time to ensure the precise and complete removal of the unwanted copper, thereby yielding an accurate circuit pattern. Conversely, a thinner copper foil is relatively more amenable to etching, yet it is also more susceptible to damage during processing. During surface treatment or cleaning procedures, a thinner copper foil may be prone to scratches or localized damage due to the impact of fluid flow or chemical etchant aggression. Consequently, a more delicate and cautious processing approach is imperative to safeguard its integrity.

4. Electromagnetic Performance

Thick copper foil confers superior electromagnetic shielding capabilities. In high-reliability equipment with stringent electromagnetic compatibility (EMC) requirements, such as medical device FPCs, a thick copper foil serves as an effective barricade against external electromagnetic interference ingress into the circuit, while also curtailing the leakage of electromagnetic signals emanating from the internal circuitry. This shielding efficacy is predicated on the principle of leveraging copper's excellent electrical conductivity to reflect and absorb electromagnetic radiation. Conversely, a thinner copper foil exhibits relatively weaker electromagnetic shielding characteristics. However, in applications where the electromagnetic shielding demands are less exacting, a thinner copper foil can adequately meet the basic circuit functionality prerequisites while imparting enhanced portability and flexibility to the FPC.

In conclusion, the judicious selection of copper foil thickness in FPC production represents a critical step. Shenzhen Huaruixin Electronics Co., Ltd., armed with its profound professional acumen and cutting-edge technology, is poised to assist customers in making optimal choices that align with their specific application needs. We wholeheartedly welcome both new and existing customers to engage in open communication and knowledge exchange, jointly exploring and advancing the frontiers of FPC technology and its diverse applications.

Let’s talk! We’ll provide the perfect solution for you!

-

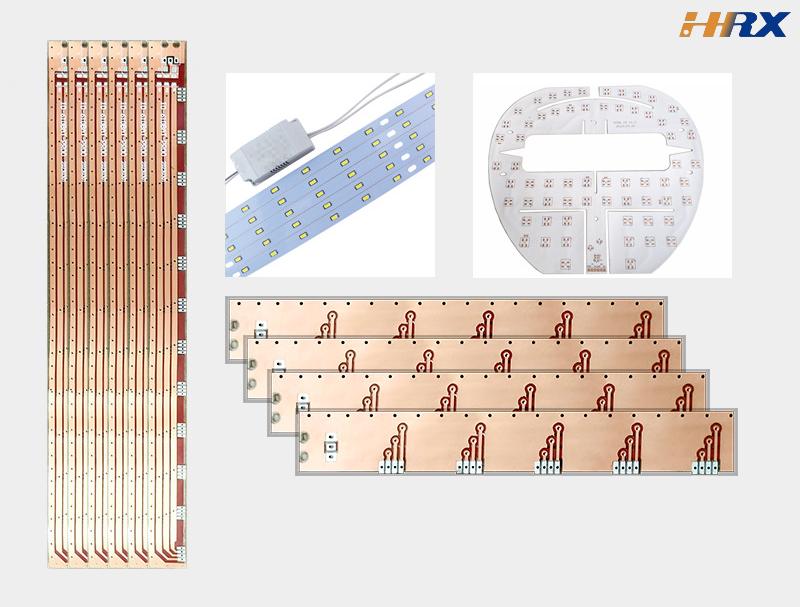

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP