Search

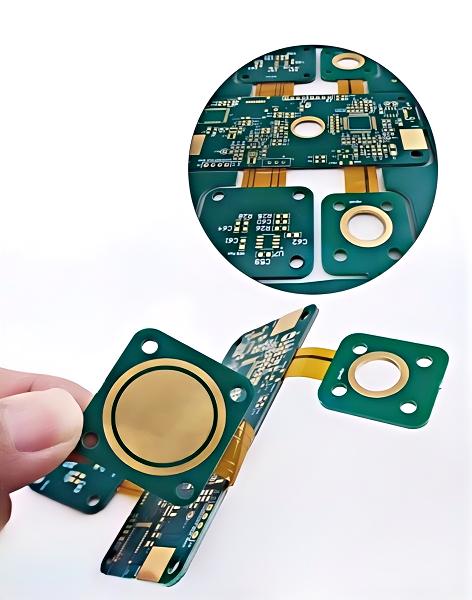

Hot Pressing Process Upgrade: The Crucial Technology for Enhancing the Bonding Strength of FR4 Reinforced Plate and FPC

- Oct 21,2024

-

Share

In the realm of modern electronic manufacturing, the flexible printed circuit board (FPC) is prevalently utilized in diverse electronic products due to its thin and flexible attributes.

Nevertheless, the mechanical strength and environmental resistance of FPC have been the focus of engineers.

Through the improvement of the hot pressing process, we have successfully augmented the bond strength between the FR4 reinforced plate and the FPC. This not only boosts the mechanical strength of the FPC but also significantly enhances its reliability in high-temperature or vibration environments.

This paper will elaborate on the specific measures and technical points of this process upgrading in detail.

Firstly, the Basic Principle of the Hot Pressing Process

The hot pressing process aims to solidify the adhesive between the FR4 reinforced plate and the FPC through heating and pressurization, thereby achieving a close combination of the two. The traditional hot pressing process has certain issues, such as inaccurate temperature control and uneven pressure distribution, resulting in inadequate bonding strength.

Secondly, the Improvement Measures of the Hot Pressing Process

1. Precise Control of Hot Pressing Parameters

Temperature Control

• Optimize the Temperature Setting: Determine the optimal hot pressing temperature range through experiments, typically between 150-180 °C. Excessively high or low temperatures will impact the curing effect of the adhesive.

• Temperature Uniformity: Employ high-precision temperature control equipment to ensure uniform temperature distribution during hot pressing, avoiding local overheating or underheating.

Pressure Regulation

• Appropriate Increase of Pressure: Based on the material characteristics and thickness, appropriately increase the hot pressing pressure to ensure close contact between the FR4 reinforced plate and the FPC.

• Uniform Pressure Distribution: A multi-point pressure control system ensures uniform pressure distribution throughout the hot pressing area.

Time Management

• Extend the Hot Pressing Time: Appropriately extend the hot pressing time to ensure full penetration and curing of the adhesive.

• Avoid Excessive Heating: Set a reasonable time limit to prevent material damage caused by excessive heating.

2. Select a High-Performance Adhesive

• High-Temperature Adhesive: Choose high-temperature resistant and high-strength epoxy resin adhesive to improve the bond strength.

• Uniform Adhesive Coating: Utilize automatic coating equipment to ensure the uniform distribution of the adhesive on the surface of the FR4 reinforced plate and FPC.

3. Material Surface Treatment

• Surface Cleaning: Before hot pressing, employ ultrasonic cleaning or plasma cleaning technology to thoroughly remove oil and dust on the material surface.

• Surface Activation: Through plasma treatment or chemical treatment, enhance the activity of the material surface and improve the bonding effect.

4. Process Optimization

• Preheat Treatment: Preheat the FR4 reinforced plate and FPC before hot pressing to reduce thermal stress and enhance the bonding quality.

• Slow Cooling: After the completion of hot pressing, employ a slow cooling process to avoid internal stress concentration caused by rapid cooling.

5. Upgrade the Equipment

• High-Precision Hot Press: Introduce high-precision hot press equipment to ensure the accuracy of temperature, pressure and time control.

• Automated Production Lines: Automate production to enhance production efficiency and consistency.

6. Quality Inspection and Feedback

• Bond Strength Test: Conduct regular tensile tests, peel strength tests, etc., to evaluate the bond strength.

• Data Analysis and Feedback: Collect production data, analyze the influence of process parameters on the bonding strength, and adjust the process parameters in a timely manner.

7. Environmental Control

Temperature and Humidity Control: Control the temperature and humidity in the production environment to prevent material property changes caused by environmental factors.

• Dust Prevention Measures: Take effective dust prevention measures to ensure the cleanliness of the production environment.

Thirdly, the Improvement Effect and Application Prospect

Through the aforementioned improvement of the hot pressing process, the bonding strength between the FR4 reinforced plate and FPC has been significantly enhanced, and the mechanical strength and environmental resistance of the FPC have been greatly improved. This process upgrade not only enhances the product quality but also extends the service life of the product and is widely applied in smart phones, wearable devices, and other fields.

The upgrading of the hot pressing process is one of the key technologies for improving the performance of FPC.

Through precise control of hot pressing parameters, the selection of high-performance adhesives, the optimization of the process flow, and other measures, we have successfully realized the high-strength combination of the FR4 reinforced plate and the FPC.

In the future, with the continuous advancement of technology, the hot pressing process will play a more significant role in the field of electronic manufacturing.

It is hoped that the sharing of this article can provide useful references for engineers and technicians engaged in related fields and jointly promote the progress of electronic manufacturing technology.

If you have any questions or suggestions, you are welcome to email sales@hrxfpc.com to discuss and exchange, and make progress together.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP