Search

FPC Reinforcements: Key Considerations in Design and Production

- Nov 08,2024

-

Share

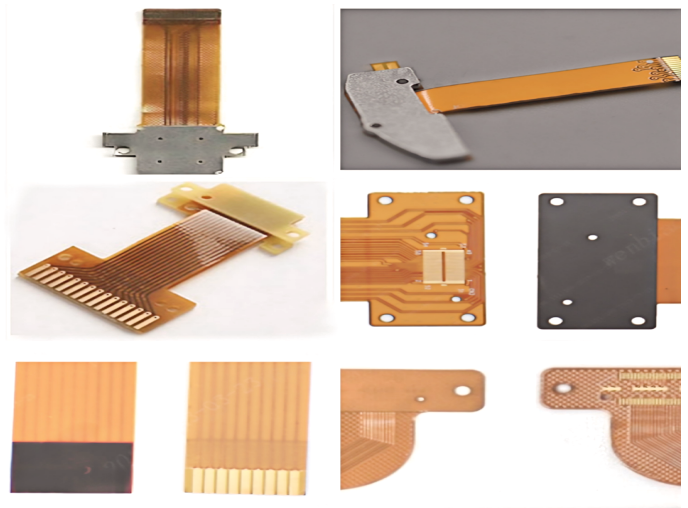

In the domain of Flexible Printed Circuit (FPC) design and production, the selection of the appropriate reinforcement material is of paramount significance. Shenzhen Huaruixin Electronics Co., Ltd., a professional FPC manufacturing and sales enterprise, is here to impart some valuable insights.

There exist several types of FPC reinforcements:

1. PI reinforcement (Polyimide): Renowned for its outstanding heat resistance and flexibility.

2. FR-4 reinforcement (Fiberglass Epoxy): Provides high mechanical strength and is suitable for applications demanding durability.

3. Stainless steel reinforcement: Offers exceptional strength and corrosion resistance.

4. Aluminum reinforcement: Robust and capable of handling substantial loads.

5. PET reinforcement (Polyethylene Terephthalate): A cost-efficient option with moderate flexibility.

6. Acrylic reinforcement: Economical and able to meet basic reinforcement requirements.

When choosing a reinforcement material, multiple factors come into consideration:

Mechanical Strength:

If specific parts of the FPC are required to withstand high mechanical forces or external pressures, materials such as FR-4, stainless steel, or aluminum are optimal choices. For instance, in industrial applications where the FPC is exposed to vibrations and impacts, stainless steel reinforcements have been successfully employed to guarantee the durability of the circuit.

Temperature Resistance:

For FPCs that need to undergo high-temperature soldering or operate in high-temperature environments, PI or FR-4 materials are frequently preferred. In the electronics manufacturing sector, where components are subjected to high temperatures during the soldering process, PI reinforcements have demonstrated high efficacy in maintaining the integrity of the FPC.

Flexibility Requirements:

If the reinforcement needs to retain a certain degree of flexibility, flexible materials such as PI or PET are more favorable options. Rigid materials like FR-4 or metals are not suitable for applications where flexibility is an essential requirement. For example, in wearable devices where the FPC needs to conform to the body's movements, PI or PET reinforcements are commonly utilized.

Cost Considerations:

For cost-sensitive products, materials like PET or acrylic can be selected as they are more economically viable. In the consumer electronics market, where cost constitutes a major factor, PET reinforcements are frequently adopted to keep production costs low without compromising excessively on performance.

Environmental Adaptability:

In harsh working conditions such as high temperatures, high humidity, or chemical corrosion, materials like PI and stainless steel perform well. For instance, in automotive applications where the FPC is exposed to extreme temperatures and vibrations, PI reinforcements are utilized to ensure the reliability of the electrical connections.

For high-temperature and high-reliability applications, materials such as PI, FR-4, and stainless steel are the prime choices due to their high strength and temperature resistance. When flexibility and lightweight are of the utmost importance, PI or PET materials are preferred. If high-strength support is necessary, FR-4, stainless steel, or aluminum are the preferred options. And for cost-sensitive consumer products, PET or acrylic materials are the economical solutions.

At Shenzhen Huaruixin Electronics Co., Ltd., we possess extensive experience in FPC design and production. Our team of experts is committed to providing high-quality FPC solutions that fulfill the diverse requirements of our customers. Whether you are a new or old acquaintance, we warmly welcome you to communicate and exchange ideas with us. Let's collaborate to create superior FPC products for a wide array of applications.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP