Search

FPC Product Structure Design: Key Considerations and Insights

- Jan 12,2025

-

Share

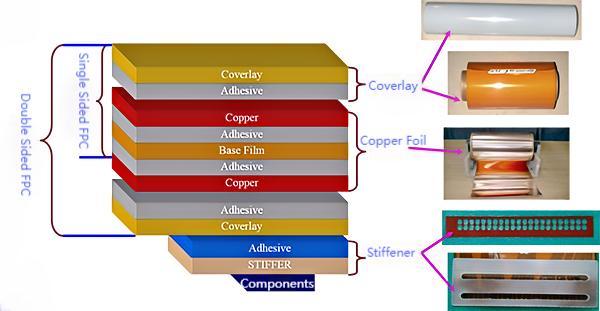

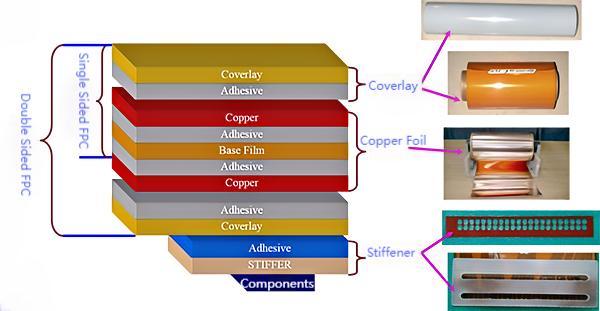

In the highly dynamic realm of electronics manufacturing, Flexible Printed Circuits (FPCs) have emerged as a linchpin component. Today, let's delve into the crucial considerations when it comes to designing and fabricating FPC products, especially with regard to their intricate structural combinations involving materials such as Single Sided FPC, Double Sided FPC, Coverlay, Copper Foil, Stiffener, and Components.

Single Sided FPC: When dealing with single-sided FPCs, trace routing stands as one of the foremost concerns. Designers must meticulously ensure an efficient utilization of space while rigorously maintaining proper impedance control. The thickness and flexibility of the base substrate play an indispensable role. A thinner laminate might confer enhanced flexibility but could introduce handling conundrums during the production phase. Shenzhen Huaruixin Electronics Co., Ltd., leveraging its wealth of experience, has ascertained that through astute layout optimization, production yields can be substantially augmented. For instance, we deliberately eschew sharp bends in the traces, as these can precipitate cracking over time, compromising the integrity of the circuit.

Double Sided FPC: In the case of double-sided FPCs, precise alignment during the manufacturing process is of paramount importance. The via holes necessitate exacting drilling and plating procedures to guarantee unfailing electrical connections between the two sides. Our company deploys state-of-the-art drilling and plating methodologies to mitigate the risks of open circuits or short circuits. Moreover, the selection of the dielectric material sandwiched between the two copper layers wields a significant influence on signal integrity. We conduct comprehensive and exhaustive testing regimens to cherry-pick the most apt material in accordance with the specific exigencies of each application.

Coverlay: The coverlay functions as a critical protective shield for the FPC. It must adhere tenaciously to the underlying copper traces and furnish reliable insulation. During the lamination process, the regulation of temperature and pressure emerges as the linchpin. An overly elevated temperature can instigate coverlay deformation or delamination, whereas inadequate pressure will culminate in subpar adhesion. At Shenzhen Huaruixin Electronics Co., Ltd., we have painstakingly calibrated our lamination parameters over the years, drawing on our extensive experience, to ensure a superlative coverlay application.

Copper Foil: Opting for the appropriate copper foil thickness is non-negotiable. Thicker foils proffer lower resistance yet curtail flexibility, while thinner foils might falter when confronted with high current densities. In the etching process, the mastery of etch rate and uniformity is pivotal to attaining precise trace widths. Our production team maintains an unwavering vigil over the etching process to satisfy the exacting tolerances mandated by modern electronics.

Stiffener: Stiffeners are incorporated to impart mechanical robustness in specific zones of the FPC. The selection of materials and the attachment modality demand scrupulous deliberation. Diverse applications beckon for varying degrees of stiffness. For example, in the context of handheld devices, a lightweight yet rigid stiffener is the preferred choice. Our adept engineers collaborate closely with clients to zero in on the optimal stiffener material and ingeniously design the attachment points, thereby ensuring peak performance.

Components: The integration of components onto the FPC mandates precision placement and dependable soldering. The thermal profile during the soldering operation must be meticulously overseen to preclude any damage to the FPC or the components. We deploy advanced pick-and-place machines and reflow soldering ovens equipped with programmable profiles to actualize high-caliber component assembly.

Shenzhen Huaruixin Electronics Co., Ltd., as a preeminent professional FPC design, production, and sales entity boasting extensive experience, is wholeheartedly committed to sharing these invaluable insights. We are convinced that by ceaselessly refining our processes and fostering collaboration with customers and peers alike, we can spearhead innovation within the FPC industry.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP