Ensuring FPC Design Performance and Quality Meets Industry Standards

- Nov 07,2024

-

Share

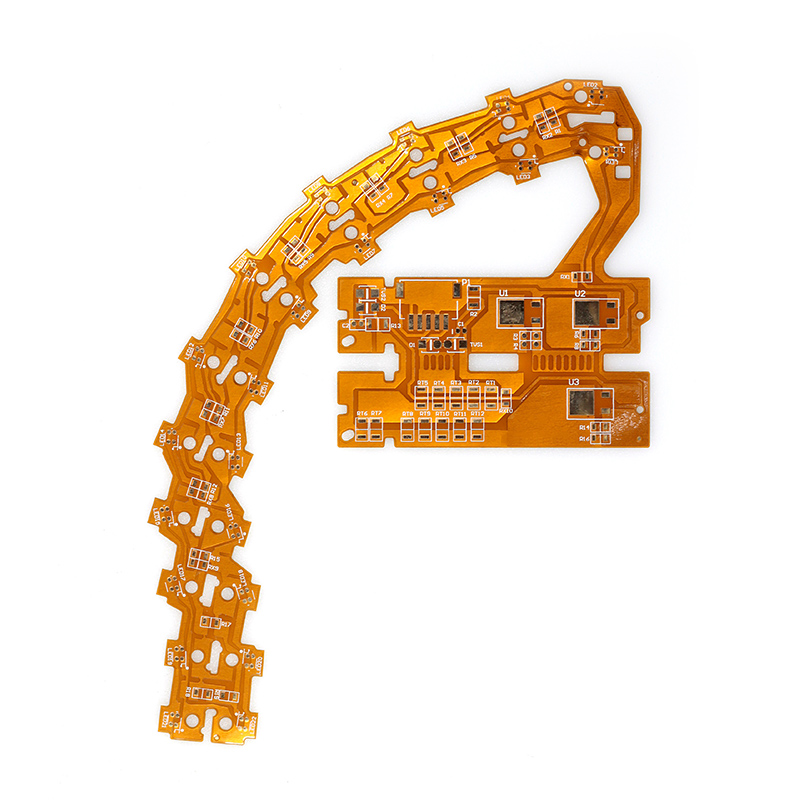

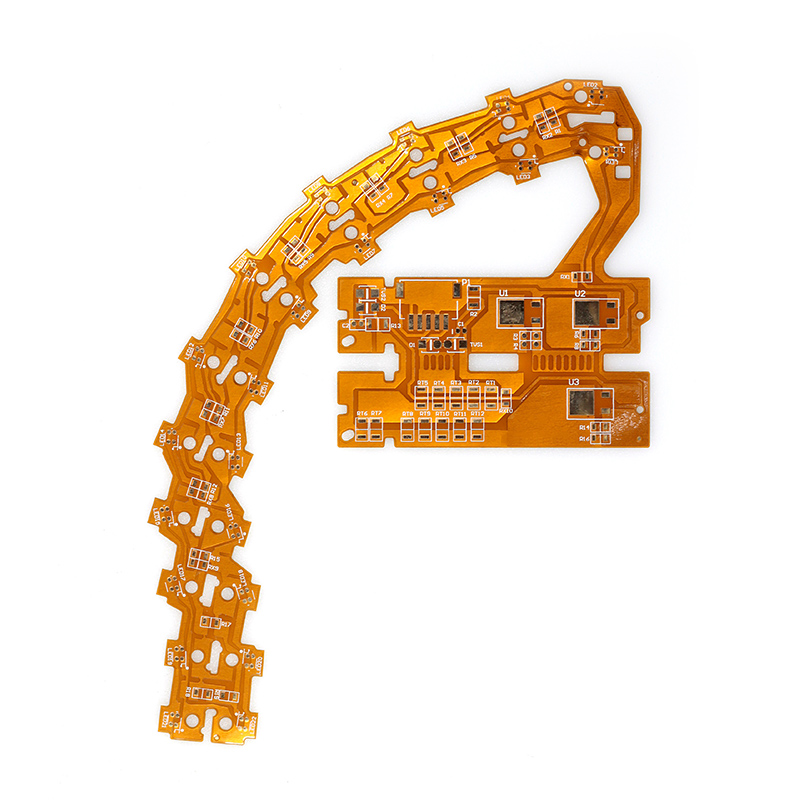

In the field of flexible printed circuits (FPCs), ensuring that the design performance and quality meet industry standards is crucial for the success of electronic products.

Understanding Industry Standards

The first step in ensuring FPC design performance and quality is to have a comprehensive understanding of industry standards. These standards cover various aspects such as electrical performance, mechanical properties, reliability, and environmental resistance. For example, standards may specify requirements for conductor resistance, insulation resistance, signal integrity, bending radius, and temperature cycling resistance.

By familiarizing ourselves with these standards, we can design FPCs that meet the specific needs of different applications and ensure compatibility with other components in the electronic system.

Design Considerations

Circuit Layout and Signal Integrity

A well-designed circuit layout is essential for achieving optimal signal integrity. This includes minimizing signal path lengths, avoiding crosstalk between adjacent signals, and providing proper grounding and shielding.

Use advanced design tools and simulation software to analyze and optimize the circuit layout before manufacturing. This can help identify potential issues and ensure that the FPC meets the required electrical performance.

Material Selection

Choosing the right materials is crucial for FPC performance and quality. Consider factors such as electrical conductivity, insulation properties, flexibility, and temperature resistance when selecting materials.

Work with reliable material suppliers to ensure that the materials used meet industry standards and are of high quality.

Impedance Control

Mechanical Design

Consider the mechanical requirements of the application when designing the FPC. This includes factors such as bending radius, tensile strength, and adhesion to ensure that the FPC can withstand the rigors of installation and use.

Manufacturing Process Control

Quality Management System

Implement a comprehensive quality management system to ensure consistent production quality. This includes processes for incoming material inspection, in-process quality control, and final product inspection.

Shenzhen Huaruixin Electronics Co., Ltd. has a strict quality management system in place to ensure that every FPC produced meets the highest standards of quality.

Advanced Manufacturing Equipment and Techniques

Process Monitoring and Optimization

Testing and Verification

Electrical Testing

Perform comprehensive electrical testing on the FPC to ensure that it meets the required electrical performance standards. This includes tests for conductor resistance, insulation resistance, capacitance, and signal integrity.

Mechanical Testing

Environmental Testing

Reliability Testing

Conclusion

Ensuring that FPC design performance and quality meet industry standards is a complex task that requires a combination of design expertise, manufacturing process control, and testing and verification.

Shenzhen Huaruixin Electronics Co., Ltd. is dedicated to providing high-quality FPCs that meet the needs of our customers and the industry. We welcome new and old friends to communicate, learn from each other, and work together to advance the field of FPC technology.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.