Search

Does Gerber files required for PCB quote or production?

- Jun 12,2024

-

Share

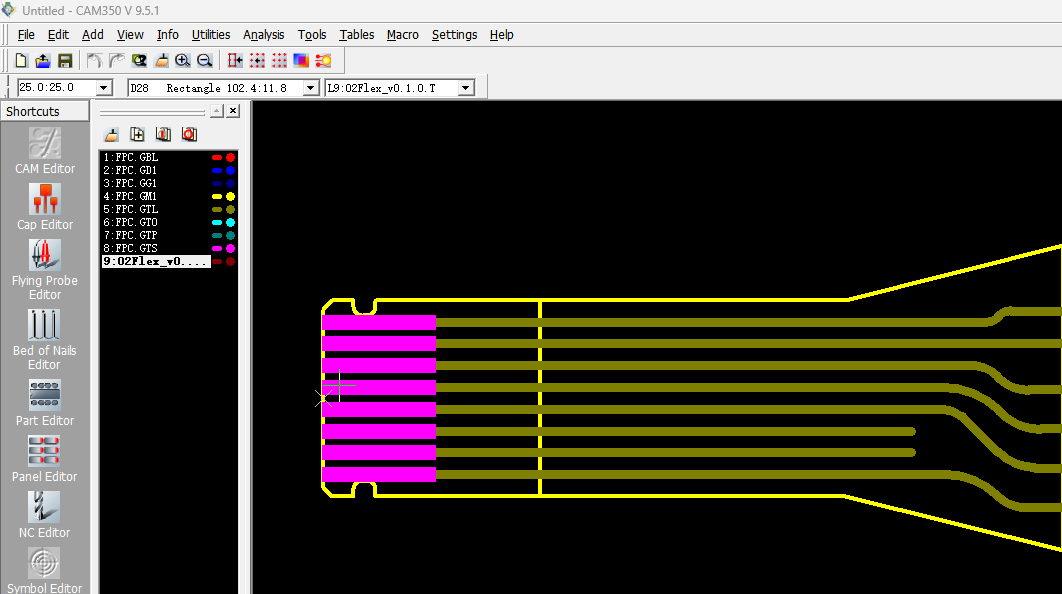

Whether you're a product developer, designer, engineer, or buyer in the PCB industry, you've likely come across the term "Gerber file." This file format is indispensable in the world of printed circuit board (PCB) manufacturing, serving as the blueprint that communicates your design to the manufacturer. Once provided to the PCB manufacturer, they will use specialized CAM software, such as Genesis 2000 or CAM350, to interpret the Gerber file. This data can then be converted into various forms like production data, stencil data, or even formal quotes.

Why the Gerber File is Crucial

The Gerber file is the most essential element when it comes to evaluating a project. It contains detailed information about the PCB layout, such as the copper traces, vias, and pads, and it ensures that the manufacturer can understand the intricacies of your design. With this file, PCB manufacturers can thoroughly assess your project and identify potential challenges early on.

However, the Gerber file alone is not enough to ensure an accurate evaluation and quote. There are six key specifications that should accompany the Gerber file to help manufacturers assess the project more precisely: (The following picture shows opening Gerber files with CAM350)

Six Key Specifications for Accurate PCB Quotes

1. Board Layer Count: The number of layers in your PCB, whether it’s a simple two-layer board or a more complex multi-layer stack-up, directly affects the manufacturing process and costs. Make sure to specify the exact layer count.

2. Material Type: The choice of PCB material (such as FR4, Polyimide, or Rogers) impacts the board's performance, especially in terms of thermal management and signal integrity. It’s important to specify this clearly to avoid any mismatch between your design and the material used.

3. Copper Thickness: Different applications require different copper thicknesses. Standard copper thickness for PCBs is often around 1 oz (35 µm), but high-current applications may need thicker copper. Include this detail to ensure the board can handle the required power.

4. Solder Mask Color: While solder mask color might seem like a purely aesthetic choice, it also plays a role in manufacturing. Green is the industry standard, but other colors like black, blue, and red are also available. Be clear about your preference.

5. Surface Finish Type: The surface finish, such as HASL, ENIG, or OSP, affects the longevity and solderability of your PCB. Specify the finish that best suits your project’s needs to ensure optimal performance.

6. Board Thickness: The thickness of your PCB can range widely depending on the application. Thicker boards may be needed for more durable designs, while thinner boards are often used for lightweight or flexible designs.

Additional Considerations for Complex Designs

If your project involves more complex designs like Rigid-Flex or HDI (High-Density Interconnect) boards, you’ll also need to provide a stack-up drawing. This drawing details how the various layers of your PCB are arranged and is crucial for ensuring that the board can be manufactured correctly.

How Detailed Documentation Leads to More Accurate Quotes

The more comprehensive your documentation, the more accurate the quote from the PCB manufacturer. A complete set of documents—beyond just the Gerber file—allows manufacturers to evaluate your design thoroughly, minimizing the chances of errors, delays, or unexpected costs down the line.

In summary, while the Gerber file is the foundation of any PCB manufacturing project, providing additional specifications like board layer count, material type, and copper thickness is equally important. By delivering all the necessary documentation, you enable your manufacturer to give you a precise and competitive quote, ensuring the success of your PCB project.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP