Search

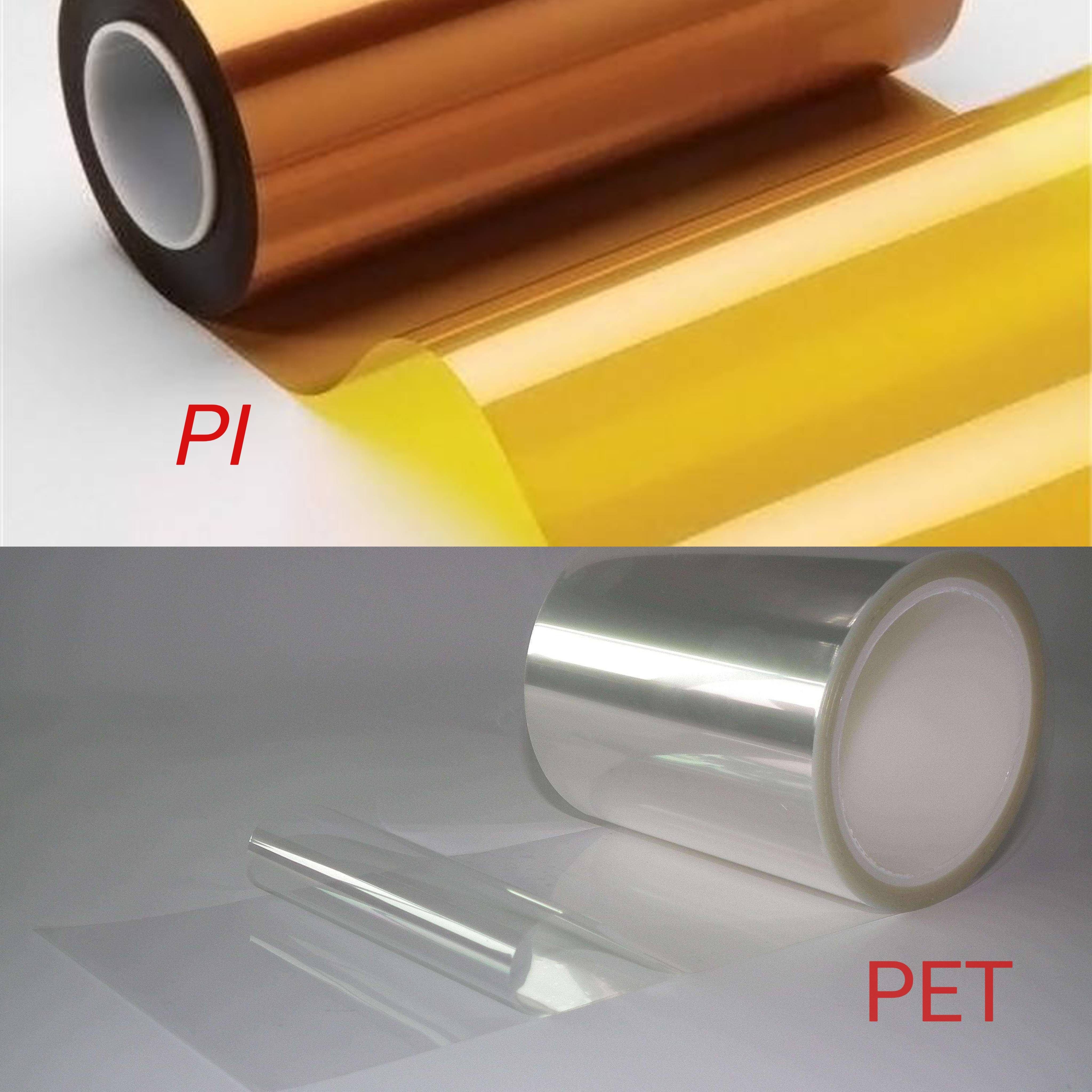

Difference between PI and PET Films in FPC and Selection Considerations

- Dec 18,2024

-

Share

In the intricate domain of Flexible Printed Circuits (FPCs), the selection of base materials, namely Polyimide (PI) film and Polyester (PET) film, wields a decisive influence over the performance and suitability of the ultimate FPC product. Shenzhen Huaruixin Electronics Co., Ltd., a distinguished and highly proficient manufacturer and purveyor of FPCs with an extensive reservoir of experience, is deeply immersed in the nuances of handling these materials. Let's embark on a comprehensive analysis of the disparities between PI and PET films and decipher how to make sagacious choices during FPC design and production.

1. Material Properties

Conversely, PET film presents a more cost-effective alternative in comparison to PI film. It commands a relatively lower price point, which endears it to applications where cost containment is a preponderant concern. For example, in uncomplicated consumer electronic artifacts such as basic calculators, the employment of PET film-based FPCs can effectively curtail production expenditures while still furnishing satisfactory electrical interconnections. PET film also possesses a certain degree of optical transparency, which can confer an advantage in specific applications where a modicum of light transmission is requisite. However, its thermal stability is circumscribed, with a maximum continuous use temperature hovering around 120℃. This thermal limitation restricts its applicability in high-temperature milieus.

2. Electrical Performance

In the realm of electrical insulation, both PI and PET films acquit themselves commendably. Nevertheless, PI film generally showcases superior dielectric properties across a broad swath of frequencies and temperatures. This implies that it can sustain stable electrical insulation even under the duress of harsh operating conditions, thereby ensuring the reliable transmission of electrical signals within the FPC. In high-frequency communication FPCs, such as those deployed in certain wireless modules, the stable dielectric characteristics of PI film are instrumental in minimizing signal attenuation and electromagnetic interference. PET film, while apt for numerous commonplace electrical applications, may not muster the same level of performance in extreme electrical environments.

3. Mechanical Strength

PI film endows FPCs with enhanced mechanical fortitude, especially when it comes to withstanding tensile and compressive forces. In FPCs that are obligated to bear substantial mechanical loads, such as those in connectors that are frequently engaged in mating and unmating operations, PI film-based FPCs can more effectively resist deformation and mechanical damage. For instance, in laptop connectors, the mechanical potency of PI film helps the FPC preserve its dimensional stability and connection integrity over an extended period. PET film, although possessing a degree of mechanical strength, is relatively more fragile and prone to damage when subjected to significant mechanical stressors.

4. Selection in FPC Design and Production

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP