Search

Customization of Transparent FPC and Related Films: Insights from Design Engineers and Consumers

- Nov 19,2024

-

Share

From the Perspective of a Design Engineer

The Significance of Technical Expertise in Design

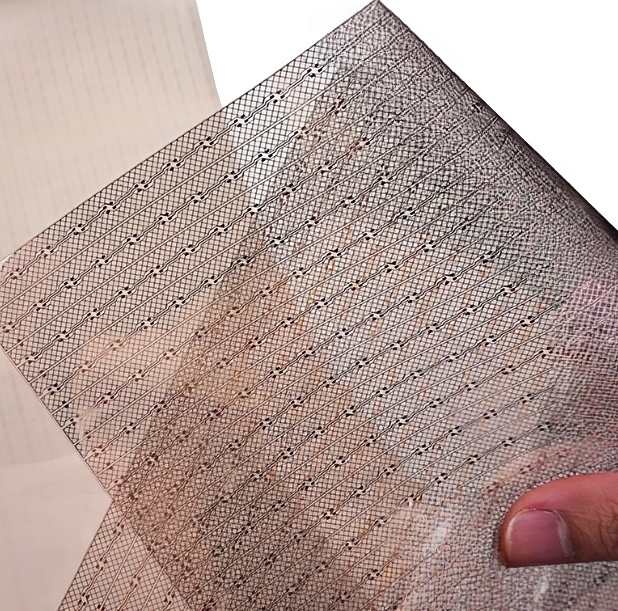

In the case of PET and PEN films with silver plating, the engineer must be well - versed in the plating process. The adhesion between the silver layer and the substrate is not just a matter of mechanical bonding but also involves chemical compatibility. Understanding the surface energy of the PET or PEN material and how it interacts with the silver plating solution is essential. A small oversight in this regard can lead to issues like poor conductivity, peeling of the silver layer, or even short circuits within the circuit.

The Role of Production Experience in Design

When it comes to customizing PET or PEN films with silver plating for display screens, production experience helps in optimizing the plating process parameters. Knowing the right temperature, plating time, and current density based on past production runs can make a significant difference. An experienced production team can also anticipate potential issues during mass production, such as variations in film thickness or non - uniform plating, and take preventive measures during the design phase. This seamless integration of design and production knowledge is what separates a successful customization project from a failed one.

From the Perspective of a Consumer

Consumer Expectations and Technical Sophistication

Moreover, I expect these components to be durable. I don't want to see any signs of degradation in the display quality over time, which implies that the materials used and the manufacturing techniques employed must be top - notch. For example, if the silver plating starts to flake off or the FPC loses its flexibility due to poor design or production, it will directly affect my satisfaction with the product.

The Impact of Professionalism on Consumer Satisfaction

For instance, in a smartphone with a customized transparent FPC for wireless charging and display connections, if the FPC fails due to design flaws or poor production quality, it can be extremely frustrating. On the other hand, when a company like Huaruixin Electronics applies its technical expertise and production experience to create a high - quality product, it not only meets but exceeds my expectations as a consumer.

In conclusion, both technical proficiency and production experience are essential to deliver products that satisfy the demanding requirements of consumers in this highly competitive electronics market.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP