Search

Customization of FPC Flexible Wireless Charging Coil Circuit Board Charging Modules: Pitfalls, Selection, and Success Stories

- Nov 19,2024

-

Share

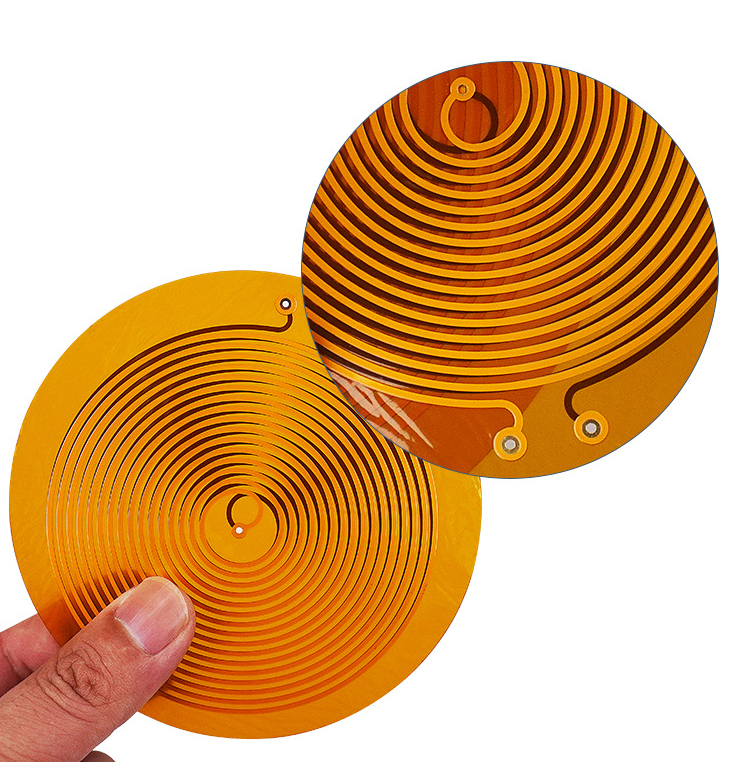

In the field of wireless charging technology, the customization of FPC (Flexible Printed Circuit) flexible wireless charging coil circuit board charging modules has become a crucial aspect. This blog will comprehensively discuss some common mistakes to avoid during the customization process, how to make the right selection, and present some successful design cases. Moreover, it will introduce Shenzhen Huaruixin Electronics Co., Ltd., a professional FPC production and sales company, and welcome new and old customers to communicate and explore together.

Common Mistakes to Avoid in Customization

1.Ignoring Compatibility Issues

One of the most frequent mistakes is not considering the compatibility between the charging module and the target device. Different devices have different power requirements and wireless charging standards. For example, some smartphones support Qi - based wireless charging with specific power ratings. If the FPC wireless charging coil circuit board charging module is not designed to be compatible with these standards, it may lead to inefficient charging or even failure to charge. Designers should thoroughly research the device's specifications that the module will be used with.

2.Poor Coil Design

The design of the FPC coil plays a vital role. Incorrect coil parameters such as the number of turns, wire thickness, and coil diameter can affect the charging efficiency and range. A coil with too few turns may not generate enough magnetic flux, while a coil with an inappropriate diameter may not be able to couple effectively with the receiving coil in the device. Additionally, improper spacing between the coil and other components on the circuit board can cause interference and reduce performance.

3. Neglecting Thermal Management

During the charging process, heat is generated. If the thermal management of the FPC wireless charging coil circuit board charging module is not properly addressed, it can lead to overheating. Overheating not only affects the performance and lifespan of the module but can also pose a safety risk. Designers should incorporate heat - dissipating materials or design proper ventilation channels to ensure the module operates within a safe temperature range.

How to Make the Right Selection

1. Consider the Charging Power Requirements

Based on the target device, determine the appropriate charging power. High - power charging modules are required for devices that need fast charging, while low - power modules may be sufficient for smaller or less power - hungry devices. For example, for some tablets that support fast wireless charging, a charging module with a power output of 15W or more might be needed.

2.Evaluate the Quality of FPC Materials

The quality of the FPC material directly impacts the flexibility, durability, and electrical performance of the charging module. High - quality FPC materials should have good conductivity, flexibility to withstand repeated bending, and resistance to environmental factors such as moisture and temperature variations. Look for materials that have been tested and proven in similar applications.

3.Look for Customization Options

A good FPC wireless charging coil circuit board charging module supplier should offer a wide range of customization options. This includes the ability to adjust coil parameters, integrate additional components such as protection circuits, and customize the shape and size of the module to fit specific device designs. Shenzhen Huaruixin Electronics Co., Ltd. is an excellent example of a company that provides extensive customization services to meet the diverse needs of customers.

Successful Design Cases

Case 1: Custom Charging Module for a Popular Smartphone Model

Shenzhen Huaruixin Electronics Co., Ltd. designed a customized FPC wireless charging coil circuit board charging module for a well - known smartphone brand. By carefully analyzing the smartphone's wireless charging requirements and internal structure, the design team optimized the coil design to achieve maximum charging efficiency. They used high - quality FPC materials that ensured flexibility and durability. The resulting charging module not only met the power requirements of the smartphone but also provided a stable and efficient charging experience. This design was highly praised by both the smartphone manufacturer and consumers.

Case 2: Charging Module for a Wearable Device

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP