Search

Connection Stability in FPC Applications: Unraveling the Intricacies and Engineering Resolutions

- Dec 17,2024

-

Share

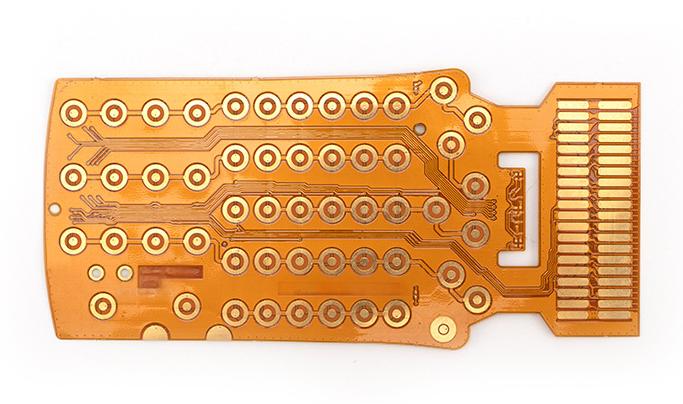

In the highly sophisticated domain of contemporary electronics, Flexible Printed Circuits (FPCs) have emerged as a cornerstone technology, enabling remarkable feats of miniaturization and flexibility. However, the Achilles' heel that often plagues FPC applications is the vexing issue of connection stability. Shenzhen Huaruixin Electronics Co., Ltd., a paragon in the FPC manufacturing and distribution landscape with a prodigious reservoir of experience, has been at the vanguard of surmounting these challenges.

I. Perplexing Problems Impinging on Connection Stability

A. Mechanical Tortures and Fatigue-Induced Deterioration

FPCs are incessantly subjected to a gamut of mechanical tribulations during their operational lifespan. Take, for instance, the FPC ensconced within a cutting-edge foldable smartphone, which serves as the vital conduit between the display panel and the motherboard. The incessant cycles of folding and unfolding, tantamount to a mechanical endurance test, can precipitate the formation of microscopic fissures within the copper traces or the adhesive laminates. These minuscule cracks, initially imperceptible, gradually propagate and culminate in intermittent or even total severance of the electrical connection. Analogously, in a wearable fitness tracker, the FPC tethering the sensor module to the central processing unit endures perpetual flexural deformations as the wearer engages in diverse physical activities. Such repetitive bending can inexorably lead to a weakening of the connection interfaces, thereby jeopardizing the seamless transmission of sensor data.

B. Oxidative Assaults and Corrosive Incursions

The malevolent forces of the environment can exact a heavy toll on the connection stability of FPCs. In environments rife with humidity or corrosive agents, the metallic constituents of the FPC, notably the copper conductors and solder joints, are rendered highly susceptible to oxidation. Consider, for example, industrial control apparatuses deployed within the caustic environs of a chemical manufacturing facility. Here, the FPCs are incessantly bombarded by corrosive gases and vapors, which instigate the oxidation of the copper traces. This oxidative process engenders an increase in electrical resistance, thereby precipitating signal attenuation and, in severe cases, connection failures. Similarly, in the realm of marine electronics, the saline-laden atmosphere can wreak havoc on FPC connectors and traces, corroding them and thereby compromising the integrity of the electrical connections.

C. Solder Joint Anomalies and Deficiencies

Defective solder joints constitute a pernicious source of connection instability. In the high-volume manufacturing of electronic devices incorporating FPCs, any lapses in the control of soldering process parameters can spawn a litany of issues, such as cold solder joints or insufficient solder deposition. A cold solder joint, characterized by its dull and granular appearance as opposed to the lustrous and homogeneous texture of a flawless joint, exhibits feeble mechanical and electrical adhesion. In a tablet device, for instance, a substandard solder joint in the FPC interfacing the touchscreen controller with the motherboard can precipitate erratic touch responses or even render the touchscreen completely unresponsive, much to the chagrin of the end-user.

II. Ingenious Solutions Devised by Shenzhen Huaruixin Electronics Co., Ltd.

A. Sophisticated Material Curation and Design Optimization

Our esteemed company spares no effort in sourcing and deploying high-caliber materials that exhibit enhanced resilience against mechanical duress and environmental adversities. We meticulously select flexible substrates endowed with superior flexibility and durability metrics. For instance, we incorporate polyimide substrates of precisely engineered thickness and mechanical characteristics, which are better equipped to withstand the rigors of repeated flexing. In the realm of design, our team of virtuoso engineers employs optimized trace routing and pad geometries. By judiciously augmenting the width and thickness of critical traces in regions prone to high current densities or frequent flexural stresses, we effectively mitigate the risk of trace rupture. Moreover, our engineers harness the power of finite element analysis (FEA) to simulate the mechanical comportment of FPCs under diverse stress scenarios and effectuate design refinements with surgical precision.

B. Protective Coating Regimens and Sealing Technologies

To thwart the insidious onslaught of oxidation and corrosion, we deploy an arsenal of protective coatings on FPCs. We utilize conformal coatings, which confer a thin yet robust protective mantle over the entire expanse of the FPC. These coatings, available in acrylic, urethane, or silicone formulations, are tailored to meet the specific exigencies of diverse applications. Additionally, for connectors and other critical connection loci, we employ hermetic sealing techniques such as potting or encapsulation. In the automotive electronics domain, where FPCs are exposed to a tempestuous cocktail of temperature extremes and mechanical vibrations, our sealed FPC assemblies ensure unwavering connection stability by barricading moisture and corrosive entities from infiltrating the sensitive circuitry.

C. Rigorous Quality Assurance in Solder Joint Fabrication

Shenzhen Huaruixin Electronics Co., Ltd. has instituted a draconian quality control regimen for solder joint formation. We deploy automated soldering apparati equipped with ultra-precise temperature and temporal controls, ensuring the reproducibility and excellence of solder joints. Both pre- and post-soldering, we conduct exhaustive inspections using state-of-the-art inspection tools, including X-ray imaging and optical microscopy. X-ray inspection empowers us to detect internal imperfections within solder joints, such as voids or incomplete solder fill, while optical microscopy facilitates a meticulous visual scrutiny of the surface quality of the joints. Any substandard solder joints are expeditiously reworked or the entire FPC assembly is summarily rejected, thereby guaranteeing that only unimpeachable products reach our discerning customers.

III. Epilogue

Let’s talk! We’ll provide the perfect solution for you!

-

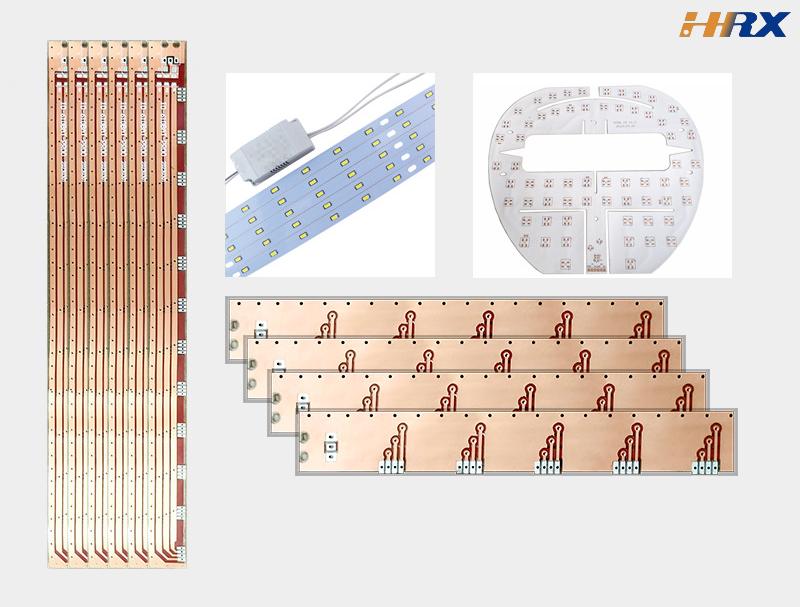

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP