In the highly sophisticated realm of modern electronics, Flexible Printed Circuits (FPCs) have emerged as a linchpin component, renowned for their remarkable flexibility, space-efficient design, and outstanding high-reliability attributes. Nevertheless, as with any technological marvel, FPCs are not immune to certain challenges during their practical utilization. One of the most prevalent and vexing issues is signal interference, which demands meticulous attention and astute solutions.

Signal Interference in FPC Applications

Signal interference can precipitate a litany of deleterious consequences, including errant data transmission, degradation of signal integrity, and even catastrophic system failures. In the context of FPCs, this interference can stem from a multitude of sources. Foremost among these is the phenomenon of crosstalk, which occurs when multiple signal traces are in close juxtaposition on the flexible circuit substrate. As electrical impulses traverse adjacent traces, they can engender unwanted electromagnetic couplings, inducing spurious voltages and currents in neighboring conductors. This insidious effect can severely disrupt the pristine signal waveform, compromising the overall functionality of the FPC assembly.

Another significant contributor to signal interference is the vulnerability of FPCs to external electromagnetic interference (EMI). In today's electrically congested environment, external sources such as high-voltage power lines, omnipresent radio frequency transmitters, or adjacent electronic devices can emit powerful electromagnetic fields. These fields can readily couple with the FPC, inducing unwanted currents and voltages that distort the intended signals, thereby jeopardizing the reliable operation of the entire electronic system.

Shenzhen Huaruixin Electronics Co., Ltd., a preeminent and highly experienced professional manufacturer and distributor of FPCs, has amassed a wealth of expertise and devised a comprehensive suite of efficacious solutions to combat signal interference issues.

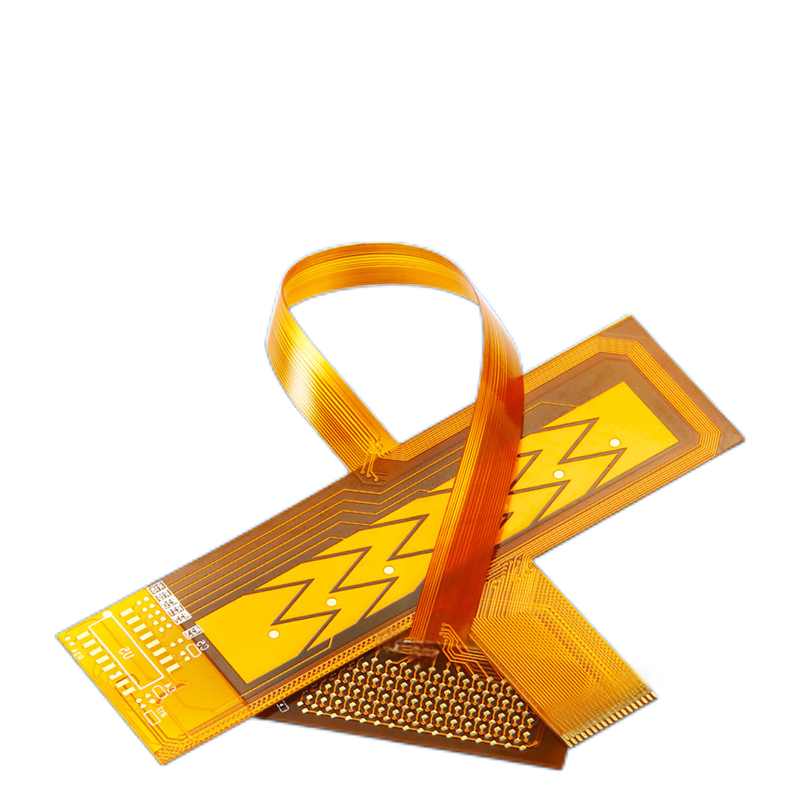

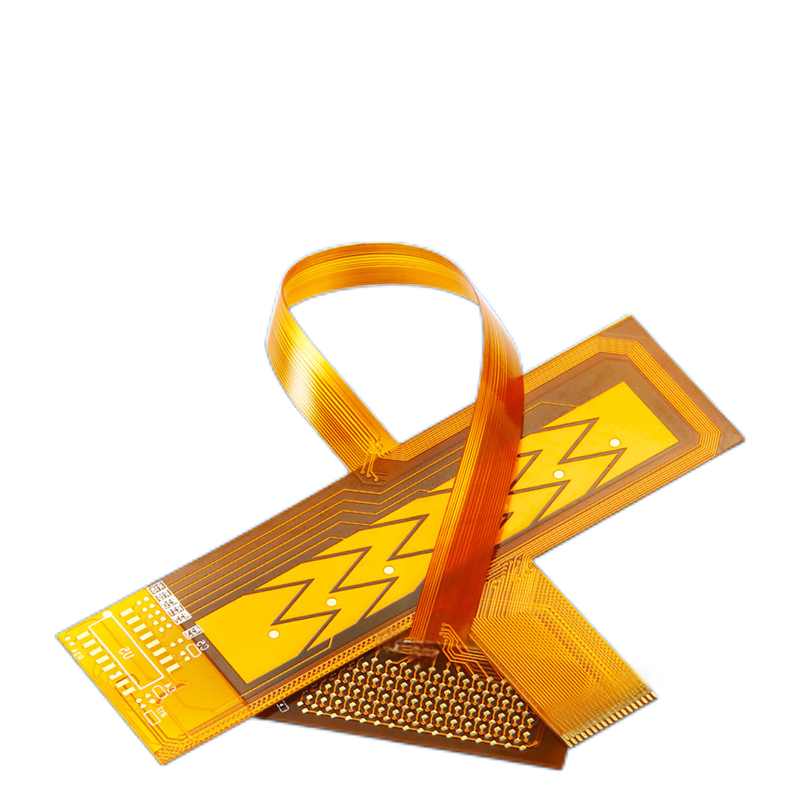

To mitigate the pernicious effects of crosstalk, our team of adept engineers employs state-of-the-art layout design methodologies. We meticulously calculate and optimize the inter-trace spacing, taking into account critical parameters such as signal frequency, amplitude, and rise/fall times. By judiciously increasing the physical separation between high-speed or sensitive signal traces or incorporating advanced shielding structures like microstrip or stripline geometries, we can effectively curtail crosstalk to negligible levels. Additionally, differential signaling techniques are frequently employed, wherein two complementary signals are transmitted in parallel. The differential receiver, equipped with sophisticated circuitry, can then extract the differential voltage, thereby canceling out any common-mode interference that may have been picked up during signal propagation.

In the battle against external EMI, our FPCs are engineered with meticulous attention to grounding and shielding strategies. We ensure the establishment of a continuous and low-impedance ground plane, which serves as a stable reference for all signal paths and facilitates the dissipation of unwanted currents. To fortify the shielding efficacy, we employ high-quality shielding layers fabricated from conductive materials such as copper foil with precise thickness and surface finish or advanced metalized films. These shielding enclosures are strategically positioned to encase sensitive signal regions, effectively acting as an impenetrable electromagnetic barrier. They reflect or absorb external electromagnetic fields, thereby safeguarding the internal signals from corruption.

Furthermore, our stringent quality control regimen encompasses comprehensive testing for signal integrity. We deploy cutting-edge testing apparatus, capable of precisely measuring parameters such as signal attenuation, characteristic impedance, and crosstalk coefficients. This meticulous testing regime enables us to identify and rectify any nascent issues during the manufacturing process, ensuring that our customers receive FPCs of the highest caliber, with minimal signal interference artifacts.

Conclusion

As the insatiable appetite for smaller, lighter, and more functionally rich electronic devices continues to escalate, the pivotal role of reliable FPC applications becomes even more pronounced. While signal interference represents a formidable obstacle, with the profound expertise and innovative solutions proffered by

Shenzhen Huaruixin Electronics Co., Ltd., these challenges can be surmounted with aplomb. We extend a warm invitation to both our esteemed existing clientele and prospective new customers to initiate a dialogue and engage in fruitful discussions with us. Together, we can embark on a journey of exploration and discovery, unearthing novel strategies to optimize FPC applications and surmount any technical impediments that may loom on the horizon. Our unwavering commitment to quality and ceaseless innovation in FPC manufacturing endows us with the confidence to assure you that your electronic designs will achieve peak performance and reliability.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.