Flexible Printed Circuits (FPCs) have become an indispensable component in modern electronics, powering everything from smartphones to medical devices. Their lightweight, flexible, and compact nature allows them to fit into tight spaces, making them ideal for portable and wearable technologies. Despite their small size, FPCs play a critical role in the performance and durability of electronic devices.

However, producing an FPC is not as simple as creating a standard circuit board. Due to their flexible nature, FPCs require a series of auxiliary materials to reinforce certain sections, improve durability, and enhance performance. Below, we will explore the essential auxiliary materials used in FPC assembly and how they contribute to its overall functionality.

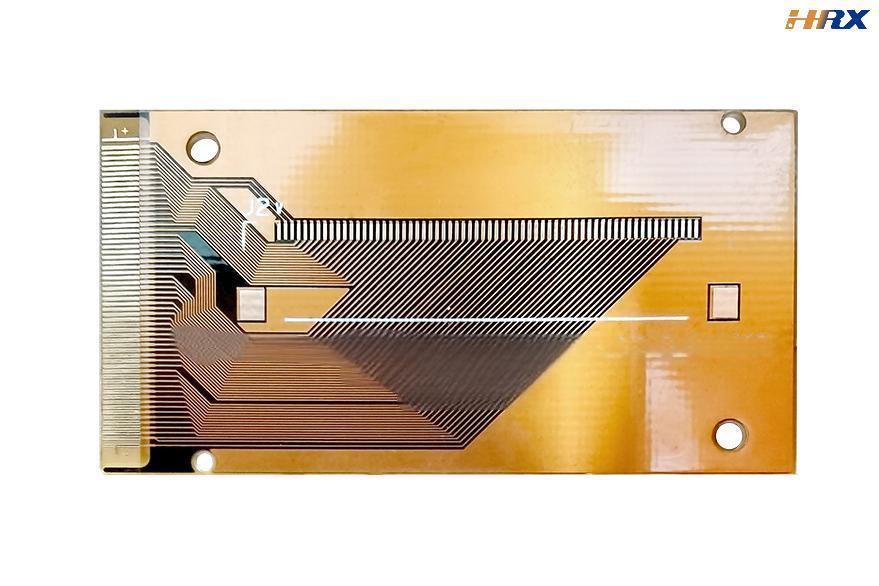

1. Stainless Steel Stiffener

One of the most commonly applied auxiliary materials in FPCs is the stainless steel plate, used for local reinforcement. This process involves attaching a thin stainless steel sheet to specific areas of the FPC where extra strength is required. This reinforcement is crucial in regions that are prone to bending, as it prevents excessive flexibility that could lead to damage or malfunction. For example, in FPCs used in consumer electronics, reinforced areas are often present near connection points or high-stress zones.

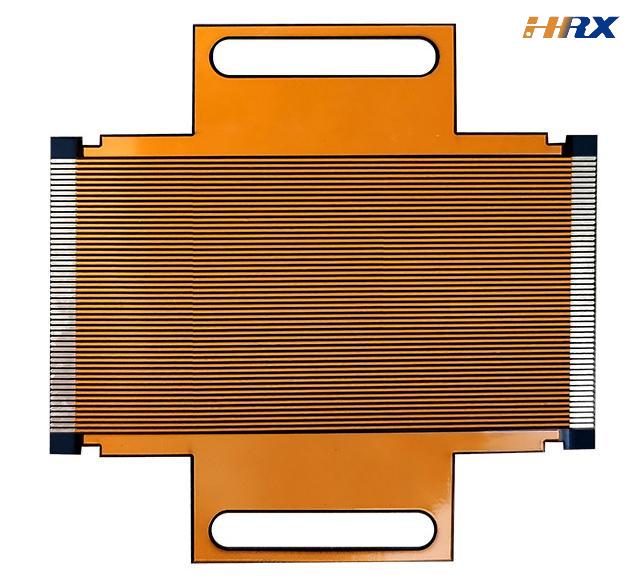

2. PI (Polyimide) Stiffener

Polyimide, or PI, is another vital material in FPC assembly. It is typically applied as a reinforcing film to improve the thickness and strength of the circuit, particularly on the back of the gold fingers (the contact points on the FPC). PI films offer excellent thermal stability, making them resistant to high temperatures. This is important because the gold finger area often undergoes repeated insertion and removal in connectors, increasing the likelihood of wear and tear. The added PI layer provides a cushion of protection while maintaining the flexibility of the FPC.

3. FR4 Stiffener

FR4, a glass-reinforced epoxy laminate, is frequently added to specific areas of the FPC to increase its thickness, providing structural integrity during insertion and removal operations. This is particularly useful in applications where the FPC needs to function like a rigid board in certain areas, such as when connected to other components that require firm contact points. By adding FR4, manufacturers can combine the benefits of both flexibility and rigidity in a single FPC.

4. EMI (Electromagnetic Interference) Shielding Film

In applications where electromagnetic interference (EMI) is a concern, such as in mobile phones, an EMI shielding film is applied to FPCs. This film is designed to protect the circuit from unwanted electromagnetic signals that could disrupt performance. EMI shielding is crucial in communication devices and wearable electronics, ensuring signal integrity and preventing cross-talk between circuits.

5. Metal domes

Metal domes, also known as tactile switches, are a key auxiliary material in FPCs, especially in products that require user interaction, such as keyboards or control panels in medical devices. These switches provide tactile feedback when pressed and are often mounted onto the FPC itself. The use of dome switches enhances the durability and reliability of user inputs, ensuring that the device operates smoothly under repeated use.

6. Adhesive Tapes

Adhesive tapes are widely used in FPC assembly for bonding components together or securing the FPC within a product. For instance, in mobile phones, adhesive tape is used to attach the FPC to the display or internal chassis, ensuring the circuit remains in place during use. The flexibility and strength of these tapes are critical in maintaining the compact and lightweight nature of modern devices.

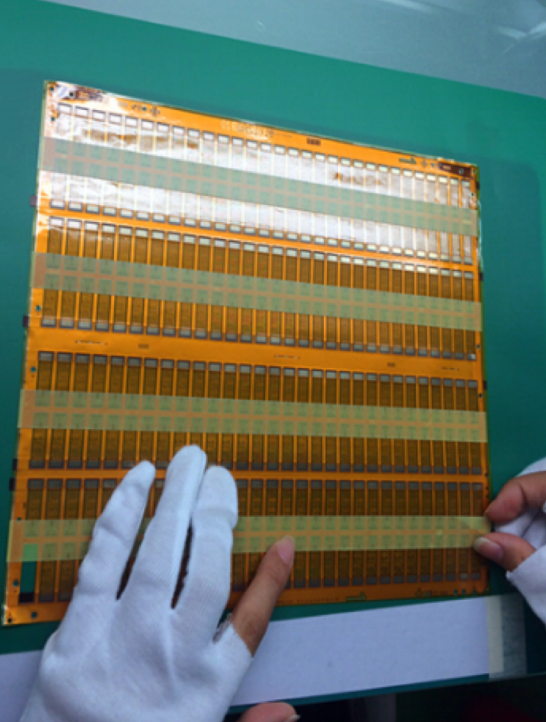

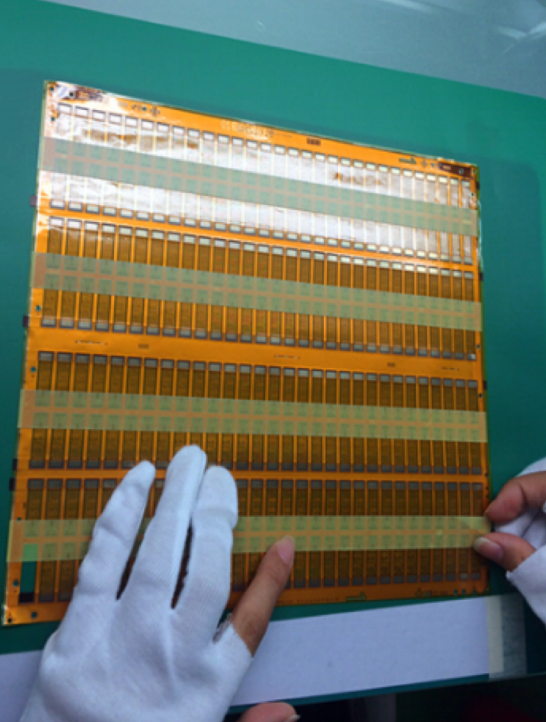

Precision in FPC Assembly

The assembly of an FPC requires a meticulous, detail-oriented approach. Each auxiliary material serves a specific purpose, ensuring that the final product meets the demands of modern technology. Stainless steel plates prevent bending in high-stress areas, PI films and FR4 reinforce the structural integrity, and EMI shielding keeps signals clean and uninterrupted. Meanwhile, dome switches and adhesive tapes contribute to functionality and ease of use in applications ranging from consumer electronics to medical devices.

It’s often said that "slow work yields fine results," and this certainly holds true in the world of FPC assembly. Despite its delicate, compact form, the FPC is a powerful component, serving as the backbone of many portable electronic products. Its role is often compared to that of a sparrow: small but complete in its functions.

As our reliance on flexible electronics continues to grow, so too will the need for innovative FPC designs and materials. Whether it's for wearables, automotive systems, or industrial applications, the careful use of auxiliary materials ensures that FPCs remain a versatile and essential part of modern technology.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.