Search

Choosing the Right Separation Method in FPC Design

- Nov 07,2024

-

Share

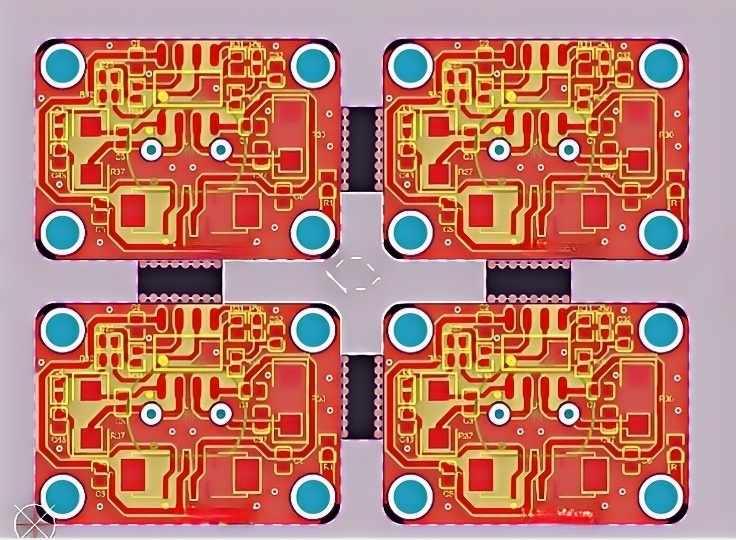

In the world of Flexible Printed Circuit (FPC) design, there are several options for separating or dividing the circuit, such as V-cut, stamp holes, milling grooves, or other methods.

Each of these methods has its own set of advantages and disadvantages, and choosing the right one depends on various factors.

Let's start with V-cut.

The V-cut method is a popular choice for many FPC designs. One of the main advantages of V-cut is its cost-effectiveness.

It is a relatively simple and inexpensive process that can be done quickly. V-cuts also allow for easy separation of the circuit boards after assembly, making it convenient for mass production.

However, there are some limitations to V-cut. It may not be suitable for designs with very thin or fragile materials, as the V-cut can cause stress on the board and potentially lead to damage. Additionally, the accuracy of the V-cut can be affected by factors such as board thickness and the quality of the cutting tool.

Stamp holes are another option for separating FPCs.

Stamp holes are small holes punched into the board that can be used for alignment or separation. One advantage of stamp holes is their precision. They can be accurately placed and sized to ensure proper alignment and separation. Stamp holes also allow for easy handling and assembly of the boards. However, stamp holes can add complexity and cost to the design. They require additional processing steps and may take up more space on the board.

Milling grooves are a more advanced separation method that offers several advantages.

Milling grooves can be very precise and can be customized to fit specific design requirements. They can also be used to create complex shapes and geometries. However, milling grooves are more expensive and time-consuming than other methods.

They require specialized equipment and expertise, and the milling process can generate dust and debris that may need to be cleaned up.

In addition to these methods, there are other separation options available, such as laser cutting or chemical etching. Each of these methods has its own unique advantages and disadvantages, and the choice depends on the specific needs of the design.

When choosing a separation method for your FPC design, it is important to consider factors such as board thickness, material properties, production volume, and cost. You should also consult with a professional FPC manufacturer like Shenzhen Huaruixin Electronics Co., Ltd. Our experienced team can provide valuable advice and guidance on choosing the right separation method for your project.

At Shenzhen Huaruixin Electronics Co., Ltd., we are committed to providing high-quality FPCs and excellent customer service. We have the expertise and resources to handle a wide range of FPC designs and requirements. Whether you need V-cut, stamp holes, milling grooves, or another separation method, we can help you find the best solution for your needs.

So, if you are in the process of designing an FPC, take the time to consider the different separation methods available and choose the one that best suits your project. And if you need any assistance or advice, don't hesitate to contact us. Shenzhen Huaruixin Electronics Co., Ltd. - your trusted partner in FPC production.

Let’s talk! We’ll provide the perfect solution for you!

-

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly. - WHAT WE DO — PCB Design Solutions — Flex PCB Production — Components Sourcing — FPC&PCB Assembly

- PRODUCTS — Single Sided Flexible Circuits — Double Sided Flexible Circuits — Multilayer Flexible Cirucits — Rigid-Flex Circuits — FPC Assembly — PCB Assembly

- CAPABILITY — FPC Capability — Rigid-Flex Capability — PCB Capability — Assembly Capability

- Copyright © 2024 Shenzhen Huaruixin Electronics Co., Ltd. All Rights Reserved.

- Design By BONTOP