Balancing Performance and Cost in FPC Design

- Nov 07,2024

-

Share

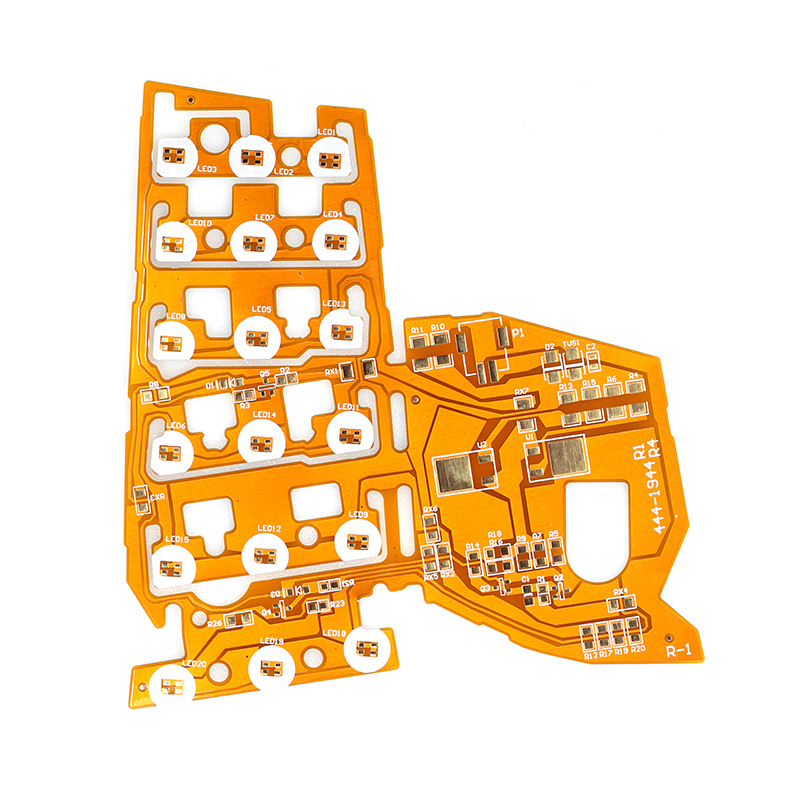

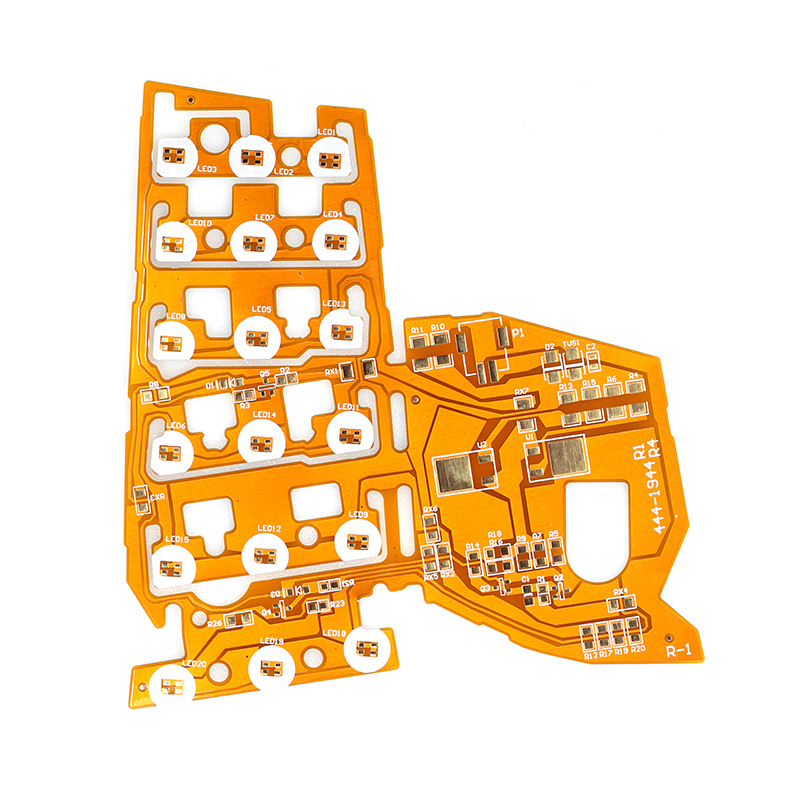

In the world of flexible printed circuit (FPC) design, finding the right balance between performance and cost is a crucial challenge. Shenzhen Huaruixin Electronics Co., Ltd., a professional manufacturer specializing in the design, production, and sales of FPCs, is here to share some insights on achieving this delicate equilibrium.

Understanding the Importance of Balance

Performance and cost are two key factors that drive the success of any FPC design. High-performance FPCs are essential for applications that demand reliability, speed, and precision. However, excessive focus on performance can lead to skyrocketing costs, making the product less competitive in the market. On the other hand, cutting costs too much can compromise the quality and performance of the FPC, resulting in dissatisfied customers and potential reputational damage.

Strategies for Balancing Performance and Cost

Material Selection

Choosing the right materials is a critical step in FPC design. High-quality materials can enhance performance but often come with a higher price tag. Consider the specific requirements of your application and select materials that offer the best balance of properties and cost. For example, polyimide films are known for their excellent electrical insulation and thermal stability but can be expensive. Alternatives like polyester films may be more cost-effective for less demanding applications.

Work closely with suppliers to understand the latest material options and negotiate favorable prices. Shenzhen Huaruixin Electronics Co., Ltd. has established strong partnerships with reliable material suppliers, enabling us to offer high-quality FPCs at competitive prices.

Layer Configuration

The number of layers in an FPC can significantly impact both performance and cost. Multilayer FPCs offer increased wiring density and better signal isolation but are more expensive to manufacture. Analyze your circuit requirements carefully and determine the optimal number of layers. In some cases, a single-layer or double-layer FPC may be sufficient, while for more complex designs, multilayer configurations may be necessary.

Consider using advanced layer stacking techniques to improve performance without adding excessive cost. For example, using microvia technology can reduce the overall thickness of the FPC and improve signal integrity.

Design Optimization

A well-designed FPC can achieve better performance while minimizing cost. Optimize the circuit layout to reduce signal path lengths and minimize crosstalk. Use efficient routing strategies to maximize the use of available space and reduce the need for additional layers.

Incorporate design for manufacturability (DFM) principles to ensure that the FPC can be produced efficiently and cost-effectively. This includes considering factors such as panelization, via placement, and component placement.

Testing and Quality Control

Implementing a comprehensive testing and quality control process is essential to ensure the performance and reliability of the FPC. However, excessive testing can add to the cost. Strike a balance by using appropriate testing methods and tools that provide accurate results without unnecessary expense.

Shenzhen Huaruixin Electronics Co., Ltd. has a state-of-the-art testing facility and a team of experienced quality control engineers to ensure that every FPC meets the highest standards of quality.

Conclusion

Balancing performance and cost in FPC design is a complex task that requires careful consideration of multiple factors. By following the strategies outlined above and working with a professional FPC manufacturer like

Shenzhen Huaruixin Electronics Co., Ltd., you can achieve the optimal balance for your specific application. Whether you are a new or old friend, we welcome you to communicate and collaborate with us to create high-quality FPC solutions that meet your needs and budget.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.