Avoiding Common Mistakes in HASL Surface Treatment: A Customer - Oriented Guide

- Nov 18,2024

-

Share

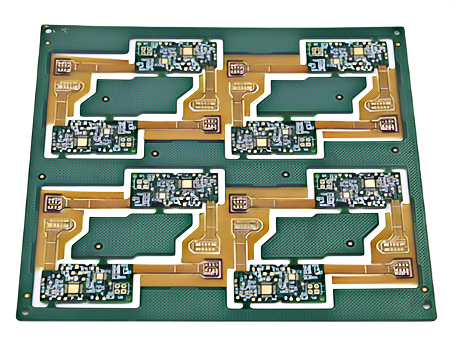

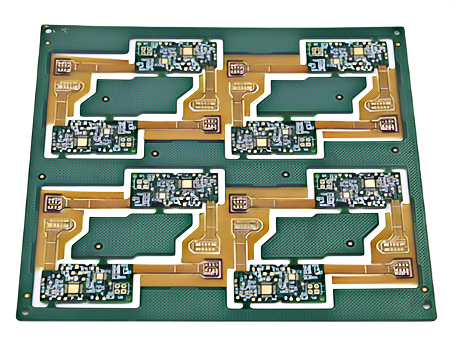

When it comes to HASL (Hot - Air Solder Leveling) surface treatment in circuit board production, there are some common errors that can really affect the quality of your product. Shenzhen Huaruixin Electronics Co., Ltd., your reliable partner in FPC production and sales, wants to make sure you know what these are and how to avoid them.

Key Design Mistakes to Steer Clear Of

1. Component Compatibility Woes

The Problem: Not thinking about how your components will handle the HASL process can be a big mistake. If you have components that are sensitive to heat, and you don't protect them during the high - temperature HASL, they can get damaged.

The Impact: Damaged components mean your circuit board might not work at all. This leads to more costs and longer waiting times as you'll need to replace those parts.

What to Do: Before you start, learn about the temperature limits and other characteristics of each component. If you have heat - sensitive ones, plan for ways to keep them cool during HASL, like adding heat - dissipation features.

2. Solder Mask Design Disasters

The Problem: Solder mask openings that are too big or too small are a common headache. Big openings let too much solder in the wrong places during HASL, causing short circuits. Small openings don't let enough solder in where it's needed, leading to weak connections.

The Impact: Short circuits are bad news - they stop your circuit board from working. Weak connections can make your device act up or stop working over time.

What to Do: Design the solder mask openings carefully, based on the size of your component pins and how you'll be soldering. You can use design software to check your work or make a sample to see if it's right.

3. Heat Distribution Headaches

The Problem: If you don't plan for heat during the HASL process when you're laying out your circuit board, you're in trouble. For example, having lots of heat - generating components close together without a way to spread the heat can cause hot spots.

The Impact: These hot spots can make the solder go crazy - it might melt too much or not be even. This can damage your board and components.

What to Do: When you're designing your layout, spread out heat - generating components. Add things like thermal vias and heat - spreading copper areas to keep the heat even. You can also use software to see how the heat will move and fix any problems.

4. Dimension Change Dilemmas

The Problem: Forgetting that the HASL process can change the size of your circuit board is a common mistake. The solder that's added can make the board thicker or change other important measurements.

The Impact: If you don't plan for this, your circuit board might not fit where it's supposed to during assembly. It could also bump into other parts and cause problems.

What to Do: Early on in your design, find out how much the size might change after HASL. You can do tests or look at past projects. Then, make sure to leave some room for these changes in your mechanical design and installation plans.

Critical Production Mistakes to Avoid

1. Solder Alloy Selection Slip - Ups

The Problem: Picking the wrong solder alloy for your circuit board's environment is a big no - no. If you use an alloy that melts too easily in a hot environment, your solder can get soft or move around when your device is working.

The Impact: This can cause short circuits or bad connections, making your circuit board perform poorly or stop working.

What to Do: Think about where your circuit board will be used. If it's in a hot place, choose an alloy that can handle the heat. If it's in a place with chemicals, pick an alloy that won't corrode.

2. Process Parameter Problems

Temperature Trouble: If the HASL temperature is too high, the solder can go wild - too much melting, too much solder in one place, and possible damage to your board and components. If it's too low, the solder won't melt right, and you'll get weak connections or not enough solder.

Time Troubles: Leaving your board in the solder too long can cause the same issues as high temperature. Not long enough, and you won't get good coverage.

Hot - Air Knife Hassles: If the hot - air knife settings like temperature, pressure, and angle are wrong, your solder won't be smooth or even.

The Problem:

The Impact: These problems mean your welding quality will be bad, and you might end up with a lot of circuit boards that don't work.

What to Do: Use good equipment to control the temperature and time. Test to find the best settings before you start making a lot of boards. And make sure to get the hot - air knife settings just right for your solder and board.

3. Cleaning and Pretreatment Pitfalls

Before HASL, if your board isn't clean, things like oil and oxides can stop the solder from sticking well.

After HASL, if you don't clean off the extra solder and other stuff left behind, it can corrode your board or mess up other parts later.

The Problem:

The Impact: Poor solder adhesion means weak connections or parts that fall off. Corrosion can make your board die early and make your device unreliable.

What to Do: Before HASL, clean your board well with the right chemicals. After HASL, use good cleaning tools and cleaners to get rid of all the extra stuff.

4.Quality Inspection Gaps

Not checking your circuit boards properly after HASL is a huge mistake. Just looking at them quickly isn't enough - you need to test how they work electrically and look for problems inside the board too.

If your inspection rules are fuzzy or you don't follow them closely, bad boards can slip through and cause big problems later.

The Problem:

The Impact: Defective boards can make your product fail more often, give you a bad reputation, and make your customers unhappy.

What to Do: Set up a good quality inspection system. Look at the boards closely for things like even solder, no short circuits, and no surface problems. Test how they work electrically and use X - rays to see inside. Make sure your inspection rules are clear and always follow them.

1. Industrial Control Circuit Board Win

We at Shenzhen Huaruixin Electronics worked on an industrial control circuit board with HASL. We made sure to protect heat - sensitive components with special cooling paths. The solder mask was perfect, and the layout was great for heat distribution. We picked a high - melting - point solder alloy for the hot environment. Our process was spot - on with temperature, time, and hot - air knife control. Cleaning was thorough, and our strict quality checks caught any issues. These boards are working great in industrial settings, showing how important these steps are.

2. Medical Equipment Circuit Board Success

In a medical equipment project, we used HASL and focused on making sure the components were safe and reliable. The design kept the components safe during HASL, and the solder mask was optimized. We chose a non - toxic, stable solder alloy. Production was careful with cleaning and process control, and our quality inspections were tough to meet medical standards. The boards are working well in medical devices, keeping patients safe.

We hope this guide helps you avoid these common mistakes and get the best results from your HASL - treated circuit boards. At

Shenzhen Huaruixin Electronics Co., Ltd., we're always here to answer your questions and work with you to make great products.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.