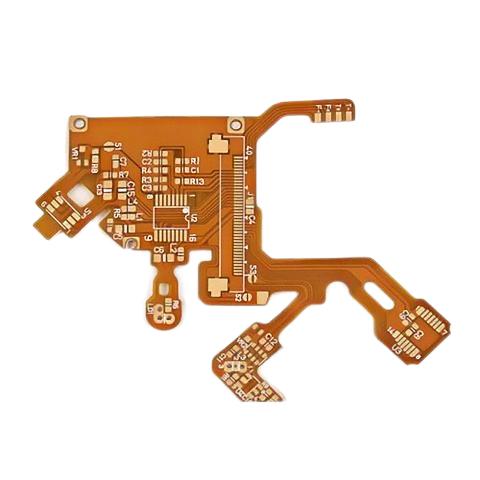

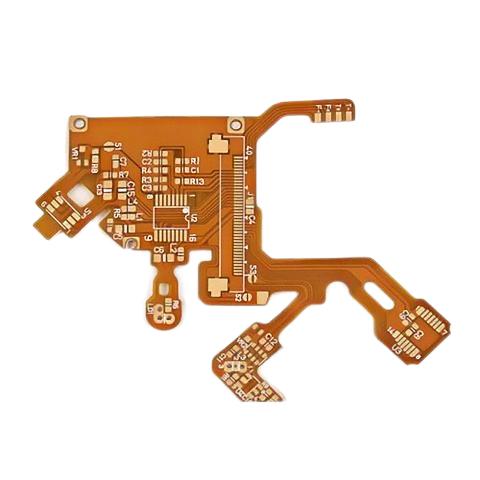

In the instrument and meter industry, Flexible Printed Circuits (FPCs) have emerged as a vital component, facilitating reliable circuit connections and signal transmissions. They are the linchpin in ensuring the stability and accuracy of diverse sensors such as those for temperature, pressure, and flow within complex and often harsh working environments. As a technical engineer, several critical aspects demand meticulous attention during the design and production of FPCs tailored for this specific application.

1. Material Selection: The Foundation of Durability

The selection of appropriate materials is the cornerstone of a successful FPC design. In industrial instrument and meter scenarios, FPCs might be subjected to extreme temperatures, high humidity levels, and exposure to various chemical substances. Take, for example, an FPC integrated into a gas flow meter operating in a petrochemical plant. Here, the base material of the FPC must exhibit exceptional chemical resistance. Polyimide (PI) is a favored choice due to its remarkable thermal stability and outstanding chemical inertness. The copper foil utilized for the conductive layer should possess not only excellent adhesion to the base material but also ensure sufficient electrical conductivity. At

Shenzhen Huaruixin Electronics Co., Ltd., we pride ourselves on our extensive reservoir of experience in meticulously choosing the most apt materials in accordance with the unique demands of different instrument and meter applications. Our team undertakes rigorous evaluation and testing of a plethora of material combinations to safeguard the long-term reliability and performance of FPCs within industrial instrument and meter systems.

2. Circuit Design Optimization: Minimizing Signal Anomalies

Efficient circuit design is the key to mitigating signal interference and guaranteeing precise sensor readings. In the signal conditioning circuitry of a temperature sensor array, for instance, the layout of the conductive traces demands painstaking planning. Thoughtful consideration must be given to reducing crosstalk between adjacent signal lines. Employing advanced grounding and shielding strategies is non-negotiable.

At Shenzhen Huaruixin Electronics Co., Ltd., our team of adept engineers harnesses state-of-the-art circuit design software. Through comprehensive simulation and in-depth analysis of electromagnetic interference (EMI) and signal integrity during the design phase, we are able to make astute adjustments. This iterative process ensures that the FPCs deliver optimal performance, even in the face of the most challenging signal processing requirements within the instrument and meter domain.

3. Precision Manufacturing Processes: The Art of Miniaturization and Accuracy

The production of FPCs for instrument and meter applications necessitates a high degree of precision. Consider the manufacturing of FPCs for a high-precision pressure transducer in an industrial calibration instrument. The etching process must be executed with pinpoint accuracy to achieve the exacting trace widths and spacings mandated by the design. The drilling and via formation procedures are equally critical, as they must ensure flawless interlayer connections.

Shenzhen Huaruixin Electronics Co., Ltd. is equipped with cutting-edge manufacturing facilities and a stringent quality control regime. We leverage advanced laser drilling and etching technologies to attain the highest levels of precision in FPC production. Our vigilant quality control team meticulously oversees each production step, ensuring that every FPC that rolls off our production line adheres to the exacting standards and tolerances essential for the instrument and meter industry.

4. Environmental Testing and Validation: Proving Resilience in the Field

To validate the reliability of FPCs in the complex and demanding industrial instrument and meter landscapes, comprehensive environmental testing is an absolute imperative. FPCs integrated into the circuitry of a liquid flow meter used in a wastewater treatment plant, for example, must endure rigorous temperature cycling, high-humidity exposure, and mechanical vibration testing. At

Shenzhen Huaruixin Electronics Co., Ltd., we have established a dedicated and well-equipped testing laboratory. Here, we subject our FPC products to a battery of simulated harsh environmental conditions. This meticulous testing regimen enables us to identify and rectify any latent weaknesses or vulnerabilities before the FPCs are deployed in actual instrument and meter installations.

In conclusion, the design and production of FPCs for the instrument and meter industry entail a multifaceted approach, with each aspect requiring careful deliberation and expert execution. At

Shenzhen Huaruixin Electronics Co., Ltd., we stand as a professional vanguard in the manufacturing and sales of FPCs, armed with a wealth of experience and a commitment to excellence. We wholeheartedly welcome new and old customers to engage in open communication, collaborative exploration, and mutual learning in this dynamic and technically challenging field. Our unwavering dedication to quality and innovation empowers us to offer top-tier FPC solutions that not only meet but exceed the exacting requirements of the instrument and meter industry.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.