In the sphere of medical monitoring apparatuses, such as electrocardiographs (ECGs), sphygmomanometers, glucometers, and other vital sign monitors, Flexible Printed Circuits (FPCs) serve as the essential conduits for linking sensors with processing chips, thereby guaranteeing the seamless and stable transmission of biomedical signals. This is of paramount importance as it has a direct bearing on the precision and trustworthiness of patient health data.

1. Biocompatibility and Safety

Medical monitoring devices often have direct or indirect patient contact. Thus, the materials incorporated in FPCs must adhere to stringent biocompatibility norms. The substrate materials, adhesives, and coatings ought not to elicit any adverse reactions, like dermal irritation or allergic manifestations. For instance, in an ECG device where the FPC lies in close proximity to the patient's epidermis, the selection of a non-toxic and hypoallergenic polyimide substrate is indispensable. Rigorous material testing and validation procedures are implemented to ensure conformity with relevant medical safety regulations. The research and development team collaborates intensively with medical device fabricators to cherry-pick the most appropriate materials that strike an optimal balance between functionality and patient well-being.

2. Signal Integrity and Noise Suppression

Accurate signal conveyance is the crux of medical monitoring. In a glucometer, for example, the FPC is tasked with faithfully relaying the electrical impulses from the glucose sensor to the signal conditioning and processing circuitry without any distortion or interference. To this end, meticulous attention must be paid to the layout of the conductive traces. Minimizing the length of signal paths and implementing proper grounding strategies are vital for curtailing electromagnetic interference (EMI) and crosstalk. Advanced simulation software and seasoned engineers are engaged to optimize the circuit blueprint. Additionally, shielding layers can be integrated into the FPC architecture to further safeguard the signals from extraneous noise sources, ensuring the integrity of the biomedical signals and the reliability of the diagnostic information.

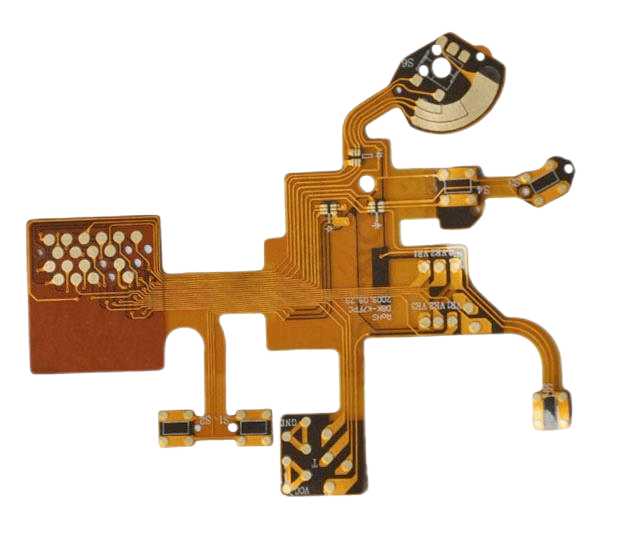

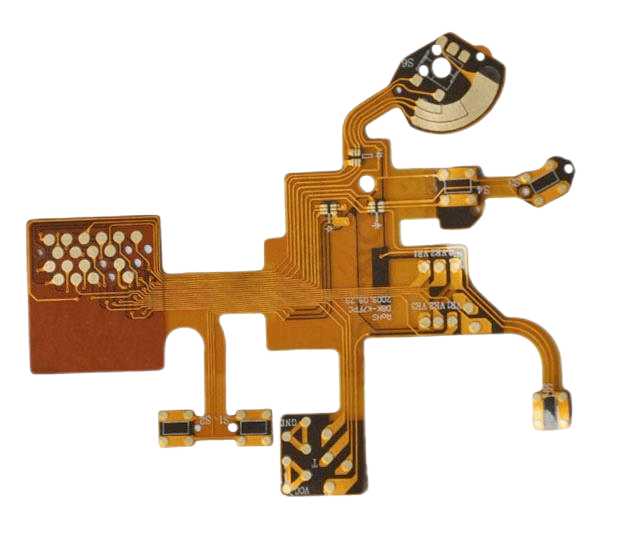

3. Miniaturization and Flexibility

The trend in medical monitoring devices is towards greater compactness and portability. FPCs present remarkable advantages in this context. Their innate flexibility empowers them to be contorted and molded to snugly fit within the constricted spaces of a device. Consider a wearable cardiac monitor, where the FPC can be artfully routed around the contours and curvatures of the device, facilitating a more ergonomic and space-efficient design. In contrast to conventional rigid circuit boards, FPCs can be folded or twisted, which proves especially advantageous when interconnecting components in a confined area. This pliability also mitigates the risk of damage due to mechanical stress during assembly or routine usage. State-of-the-art manufacturing processes, such as high-resolution etching and lamination techniques, are harnessed to fabricate FPCs with fine pitch and ultra-thin profiles that meet the exacting size and flexibility prerequisites of contemporary medical devices, thereby enabling seamless integration and enhanced user comfort.

4. Durability and Reliability

Medical devices are anticipated to possess a prolonged operational lifespan and function under diverse conditions. FPCs deployed in sphygmomanometers, for instance, must endure repeated flexing and mechanical strains. Premium-grade materials and cutting-edge manufacturing technologies are employed to augment the durability of FPCs. Stringent testing regimens, including flexural endurance assays and thermal cycling evaluations, are carried out to ascertain that the FPCs can sustain their performance over time.

In conclusion, the design and production of FPCs for medical monitoring devices mandate a holistic approach that takes into account biocompatibility, signal integrity, miniaturization, and durability.

Shenzhen Huaruixin Electronics Co., Ltd., a professional entity in the FPC manufacturing and sales domain with a wealth of experience, extends a warm invitation to both new and existing patrons to engage in dialogues and knowledge exchange. Through collaborative efforts, we can continue to propel the evolution of FPCs in the medical sector and enhance the caliber and efficacy of medical monitoring devices.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.