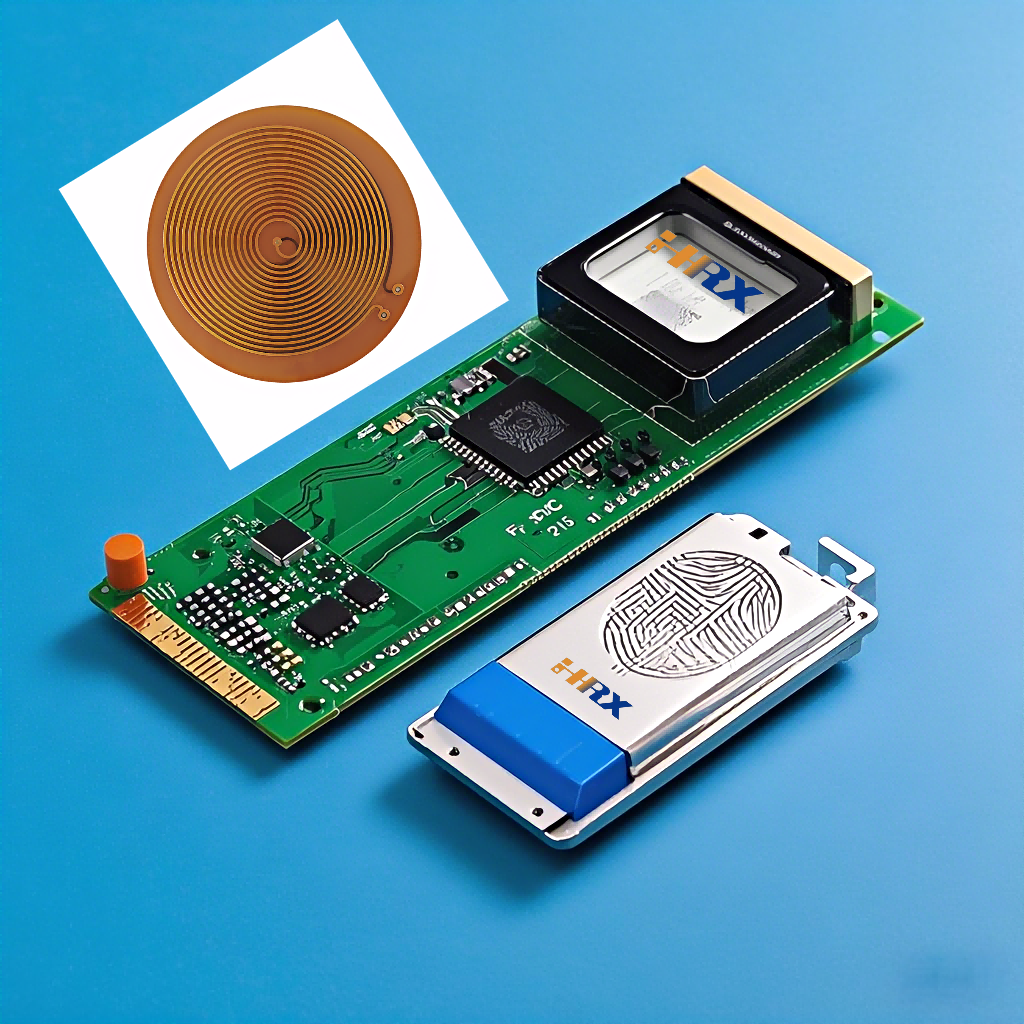

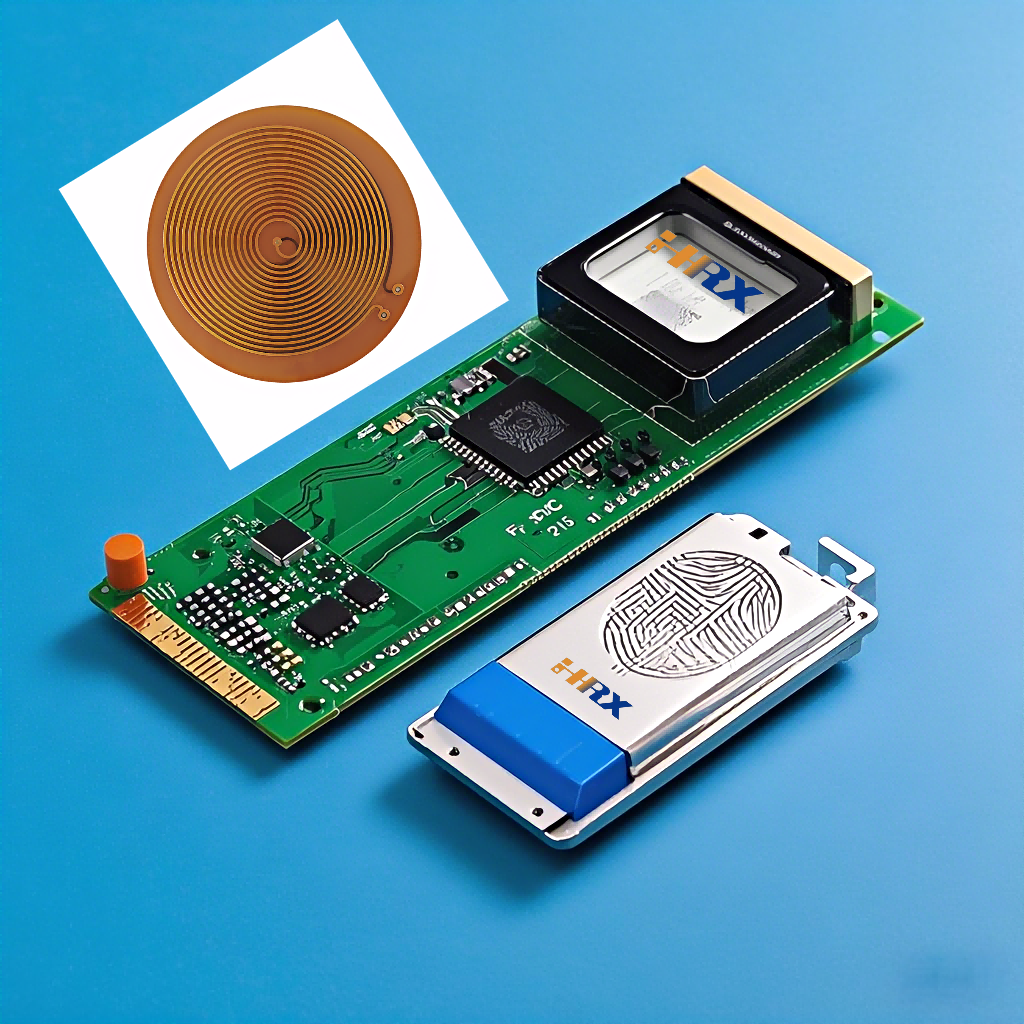

In the fast - paced and highly competitive realm of consumer electronics, the seamless integration of components is pivotal for elevating product performance and user experience. When it comes to the design and production of FPC (Flexible Printed Circuit) boards in conjunction with fingerprint recognition modules, there are several critical aspects that demand meticulous attention.

1. Material Selection

The choice of materials for FPC is of utmost importance. High - grade base films with exceptional flexibility, or flexure, and thermal stability are indispensable. Polyimide (PI) films, for example, are extensively utilized due to their remarkable high - temperature resistance and robust mechanical properties. In a notable success story, a leading smartphone manufacturer partnered with a premier FPC supplier. By incorporating advanced PI films with low coefficient of thermal expansion (CTE) in the FPC for fingerprint recognition modules, they achieved consistent and reliable performance even under extreme temperature fluctuations during extended device usage. Shenzhen Huaruixin Electronics Co., Ltd., with its wealth of experience, is proficient in selecting the most appropriate materials, considering factors such as dielectric constant and moisture absorption, for diverse FPC applications related to fingerprint recognition modules.

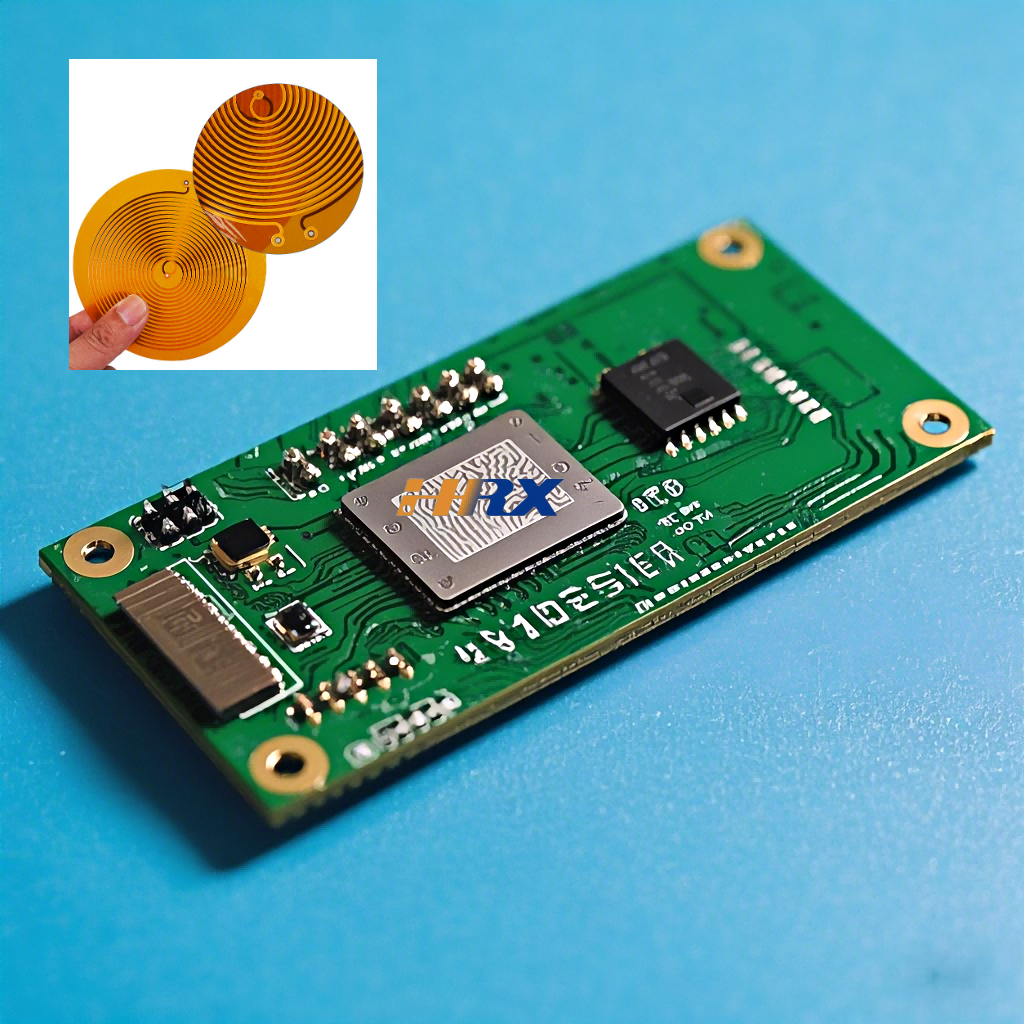

2. Circuit Layout Design

A meticulously planned circuit layout is essential. The traces on the FPC should be designed to minimize signal interference and ensure optimal impedance matching. In fingerprint recognition modules, precise and rapid signal transmission is crucial for swift and accurate fingerprint authentication. For instance, in a recent project, a tablet computer manufacturer encountered issues with false fingerprint readings. After re - engineering the FPC circuit layout by optimizing the trace width, clearance, and implementing proper grounding techniques, the problem was successfully resolved. Shenzhen Huaruixin Electronics Co., Ltd. houses a professional R & D team well - versed in high - speed circuit design principles, capable of creating highly optimized circuit layouts for FPC in fingerprint recognition modules, guaranteeing seamless signal propagation.

3. Adhesion and Bonding

The adhesion between different layers of the FPC and its connection with the fingerprint recognition module must be robust and dependable. Weak adhesion can lead to delamination over time, severely compromising the functionality of the module. A smart lock manufacturer once faced problems with intermittent connection in their fingerprint - unlocking system. Through the application of high - performance adhesives with excellent shear strength and the implementation of advanced bonding processes, such as anisotropic conductive film (ACF) bonding, they significantly enhanced the stability of the FPC - fingerprint module connection. Shenzhen Huaruixin Electronics Co., Ltd. has mastered state - of - the - art adhesion and bonding techniques, ensuring the long - term reliability of FPC - fingerprint recognition module assemblies.

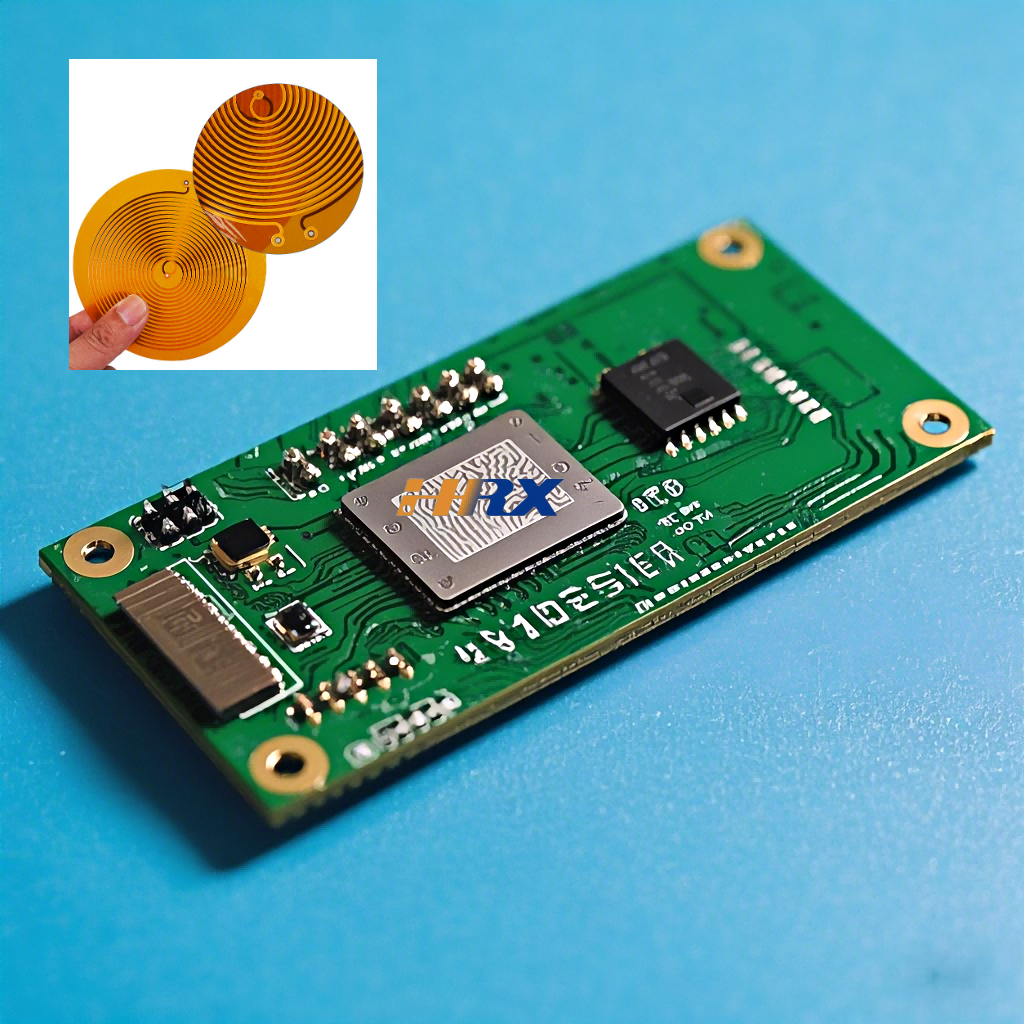

4. Dimensional Accuracy

Precision in dimensional control is non - negotiable. The FPC must be fabricated with tight tolerances to fit perfectly with the fingerprint recognition module, ensuring accurate alignment of electrical contacts. In the production of a wearable device with fingerprint - based security features, stringent dimensional control of the FPC, including controlling the flatness and profile of the FPC, enabled a compact and reliable design. Shenzhen Huaruixin Electronics Co., Ltd. employs advanced manufacturing equipment, such as high - precision CNC machines, and rigorous quality control processes, including automated optical inspection (AOI), to ensure top - level dimensional accuracy in FPC production for fingerprint recognition modules.

Shenzhen Huaruixin Electronics Co., Ltd. is a professional FPC manufacturer with extensive experience in the design and production of FPC for fingerprint recognition modules. We welcome new and old friends to engage in communication and discussion with us, with the aim of jointly driving the advancement of this field.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.

Huaruixin Electronics mainly produces printed circuit boards as the core business, to provide customers with one-stop solutions for FPC/PCB production, components sourcing and Assembly.